Page 1 of 2

Liquid Nails Question

Posted:

Wed Jan 04, 2012 10:15 pmby PSBreen

After my little set back the other day I decided to give Liquid Nails HD another try. I attached the 1/8" skin to one side of a door. I used a 9" trowel with 3/16" V notches. I spread the glue thin enough I could read through it. Would you believe it took an entire 10 oz tube to cover the door? That really seems like a lot of glue. The door is only 30 x36 with a 15 x 18 window cutout. The other issue is that you only have 20 minutes working time. I'll be real surprised if I can get it spread on an entire side and attach the skin before it hardens. Any suggestions on a glue that would give me a little more time to work? Thanks.

Posted:

Wed Jan 04, 2012 10:43 pmby StPatron

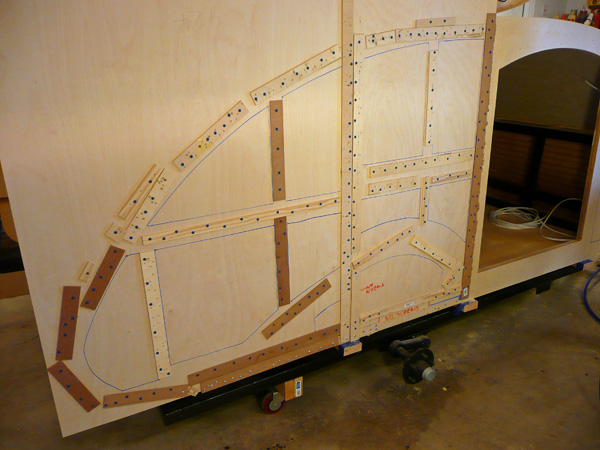

I see in your album that you are using a skeletonized plywood wall.

What are you using for a skin?

What are your plans for a final surface treatment?

Posted:

Wed Jan 04, 2012 10:47 pmby absolutsnwbrdr

Definitely seems like a lot of glue. Why are you troweling it on? Why not just run a bead around the perimeter and a few beads across the middle?

Posted:

Wed Jan 04, 2012 11:58 pmby PSBreen

We're using 3/4" ply with cutouts (cookie cutter style) for insulation and will skin it with 1/8" luan ply. Running a bead would probably work if we were attaching 2 solid sheets. With this method everything needs to be glued together to get a solid structure. The skins actually provide a lot of the strength to resist twisting and warping.

Final exterior surface will be light fiberglass, epoxy and spar varnish.

Posted:

Thu Jan 05, 2012 1:36 amby afreegreek

just use your favourite flavour of PVA and leave the liquid nails in the tube, or better yet, on the store shelf..

Posted:

Thu Jan 05, 2012 3:25 amby PaulC

afreegreek wrote:just use your favourite flavour of PVA and leave the liquid nails in the tube, or better yet, on the store shelf..

Ditto from me or use a contact adhesive that you can buy in bulk.

Cheers

Paul

Posted:

Thu Jan 05, 2012 8:48 amby PSBreen

So PVA? Would that be like Titebond glue?

Posted:

Fri Jan 06, 2012 3:49 amby Steve_Cox

I like Liquid Nails HD but never tried to used it with a notched trowel, usually just around the perimeter of a piece of plywood and maybe an X across the middle.... worked well for me. For complete coverage in doing a lamination of plywood I preferred rolling on epoxy.

Posted:

Fri Jan 06, 2012 8:50 amby Oldragbaggers

Steve_Cox wrote:I like Liquid Nails HD but never tried to used it with a notched trowel, usually just around the perimeter of a piece of plywood and maybe an X across the middle.... worked well for me. For complete coverage in doing a lamination of plywood I preferred rolling on epoxy.

+1 on the epoxy

Posted:

Fri Jan 06, 2012 9:51 amby aggie79

I used a product similar to Liquid Nails - PL Premium - to attach plywood skins to the plywood frame.

I applied a bead of the PL Premium along the perimeter of the profile, around openings, and along the "framing members". I also added some random beads across the insulation to the plywood framing. I then set the plywood skin on top and used a j-roller on the plywood skin to force the PL Premium to spread out. Then I used screws and scrap plywood as cauls to "clamp" the skin to the plywood.

This method does not result in the entire plywood framing surface area being bonded to the skin. It is however, have substantially more than enough structural strength.

Take care,

Tom

Posted:

Fri Jan 06, 2012 10:03 amby PSBreen

It's looking like my aircraft maintenance practices are making me work too hard. When we did repairs to bonded (sandwich) structures everything had to be firmly attached to the next component or it wouldn't give us the strength we needed.

I did a test panel last night with Titebond III, won't know until later today how that worked. If I can get by with a bead of adhesive instead of complete coverage then I may need to try that again. The main thing is I don't want the skins separating from the frame for a long, long time.

Posted:

Fri Jan 06, 2012 1:35 pmby aggie79

Steve,

Titebond III is a good product. I it used to bond the skins of my insulated floor. The only issue I had with it is I worked by myself and couldn't work fast enough for its comparatively short open work time.

As I now realize, most of us first timers incredibly overbuild our teardrops. In the picture below, my teardrop shell is only supported in three places - once at the middle of the floor at the front and twice at the rear sidewalls. My wife and I sat in the shell - we're about 330 pounds total and I'm about 2/3 of that - and there was minimal deflection even without the exterior plywood skin on.

When I glued the exterior sidewall skins on, I just ran a bead along the framing and not on the insulation. The picture below shows the plywood scraps and self-drilling screws that I used to "clamp" the outer skin.

This is what it looked like after the screws removed, excess plywood cut away (routed), and with screw holes filled.

Take care,

Tom

Posted:

Fri Jan 06, 2012 6:21 pmby afreegreek

ya, that's it.. EPOXY to bond skin to a plywood frame... really...are you towing the trailer or are you parking your truck on it?

honestly, I read some of the advice given to people and I want to go pound my head against a brick wall...

Posted:

Fri Jan 06, 2012 7:29 pmby vwbeamer

While I'm too cheap and Lazy to build a trailer like Tom, I respect that he does everything the very best way.

Nothing wrong with over kill if you have the time , money and patience to do it that way, and when he hooks his teardrop up he doesn't worry about it falling apart.

Posted:

Fri Jan 06, 2012 7:47 pmby 48Rob

ya, that's it.. EPOXY to bond skin to a plywood frame... really...are you towing the trailer or are you parking your truck on it?

honestly, I read some of the advice given to people and I want to go pound my head against a brick wall...

Mr. Greek,

While you post some good information here on the board, some of which I've learned new things from, and appreciate, it sure seems like you often go out of your way to troll through all the posts to find something you can contest, or some one, or some method to put down.

Please, give it a rest already.

If someone wants to spend their money on a product you feel is a waste, politely offer your opinion, then leave it alone.

Searching for posts so you can tell everyone how you have already told everyone your opinion is just getting old.

Rob