Page 1 of 1

Built Up Arched Ribs

Posted:

Mon May 07, 2012 10:24 pmby KCStudly

Some time back I recall seeing a good technique for getting the most arch out of a given board width by offsetting the arch layout slightly off the board to one side and rejoining the inside radius cutout back onto the the "crown" side of the board; rather than using a wider board and trying to get the full layout onto it and then having more waste in the end.

Did that make sense?

If so, can someone please steer me to the specifics involved in this technique or to a link? (Search came up empty.)

Thanks,

Re: Built Up Arched Ribs

Posted:

Mon May 07, 2012 10:43 pmby eamarquardt

I think I know what you mean but and if so you're going to have a weak spot unless you have multiple layers with the joints staggered.

I'm thinking of laminating the galley ribs out of multiple layers of either 1/8 ply or solid strips. I'll build a form, build a stack of strips all glued together, clamp them to the curved form, and let the glue cure. As I understand it you get very little springback.

If I use 1/8 ply there will be very little waste. If I buy solid wood, resaw it into strips, and plane to thickness there will be nearly a 50% waste.

Hope this helps.

Cheers,

Gus

Re: Built Up Arched Ribs

Posted:

Tue May 08, 2012 7:49 amby Lancie49

This will be an interesting thread.

Looking forward to learning stuff.

Re: Built Up Arched Ribs

Posted:

Tue May 08, 2012 10:11 pmby KCStudly

Gus, I've been having the same thoughts as you on using left over thin ply. The other thought I had was to do one or two wider glue ups then rip the arc lengthwise on the band saw using a feather board, then true up the sawed (sawn?) edges on the jointer or with a power plane, if needed, palm sander if not. I think this would save some effort over gluing multiples and would result in nice even finished ribs.

Re: Built Up Arched Ribs

Posted:

Tue May 08, 2012 10:59 pmby eamarquardt

KCStudly wrote:Gus, I've been having the same thoughts as you on using left over thin ply. The other thought I had was to do one or two wider glue ups then rip the arc lengthwise on the band saw using a feather board, then true up the sawed (sawn?) edges on the jointer or with a power plane, if needed, palm sander if not. I think this would save some effort over gluing multiples and would result in nice even finished ribs.

I'm have searched around and can't find anyone that sells the veneers used in the construction of cold molded boats. So, I'm going to rip some 1/8 BB and try that. I'll make some test pieces with radius's much smaller than the ribs will be to get an idea if there is any "springback". On one of the test pieces I'll clamp the ribs to the form (or even more extreme form) for a few days to "prebend" them a bit and see if that has any effect on "sprinback". I think that individual ribs will be easier as the clamping will be for a smaller section width and more uniform. I plan on making some test pieces as soon as I get back from visiting China for the next two weeks. I plan to true them up by building a "bridge" for my router, routing one side before the rib from the "mold", flip them over and true up the other side. I plan to make the mold out of short sections of angle iron screwed down to plywood. I'll test and see if an outside mold or inside mold works better. I think clamping the rib on the outside of the mold will be easier. I bought 24 spring clamps so I can clamp the heck out of the ribs.

That's my plan but I'm certainly open to suggestions or hearing from anyone with experience.

Cheers,

Gus

Re: Built Up Arched Ribs

Posted:

Tue May 08, 2012 11:19 pmby KCStudly

Re: Built Up Arched Ribs

Posted:

Tue May 08, 2012 11:35 pmby eamarquardt

Re: Built Up Arched Ribs

Posted:

Wed May 09, 2012 6:01 amby bobhenry

I am approaching the problem using sandwiched 1/2 plywood for the tiny house Caboose build. In the wall panelization biz we often have arched window and doorway openings and they are accomplished by plywood sandwich with hardwood fillers.

As I tossed away these "scraps" I thought " These would make nice bowed roof spars for a 5' wide teardrop...........

Re: Built Up Arched Ribs

Posted:

Wed May 09, 2012 7:06 amby KCStudly

Thanks for the reply Bob Henry. I am familar with the header construction you mentioned. What I'm really trying to avoid is putting screws into the edge grain of plywood, so I'm going through the different hatch rib construction techniques in my mind (built up mitered and radiused; Laminated over a form; plywood; combinations of these) looking for the easy but "correct" way.

I think the reverse of what you are suggesting (two thin plys on the outside of each rib) with the cores made from poplar or even cedar would probably be about the same effort as laminating.

Still undecided.

Re: Built Up Arched Ribs

Posted:

Wed May 09, 2012 7:52 amby bobhenry

"I'm really trying to avoid is putting screws into the edge grain of plywood."

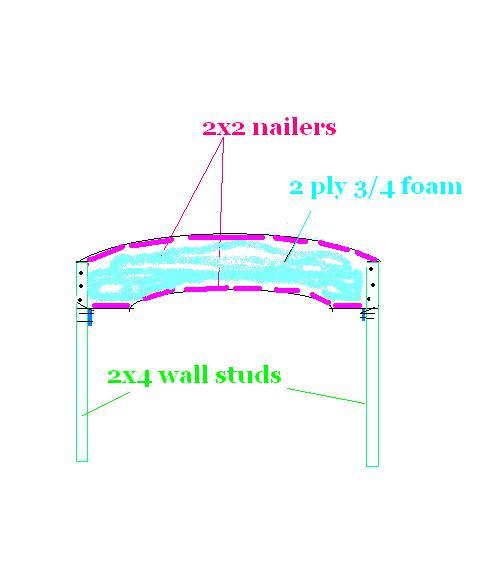

I think you missed my interpetation of the trusses I am pairing up the plywood as 2 outer faces and inserting 2x material in the center void. Maybe this will help......

This will provide me with an 1 1/2" of SFP lumber to securely screw the roof material to.

Mine in the picture is deeper because it is spanning 8' and I will be glueing and screwing the connections as they will be trapped between the roof and the ceiling panels and will not show. However, they could be glued and clamped or glued and pin nailed with little notice of the fastners when built on a smaller shallower scale.

Re: Built Up Arched Ribs

Posted:

Wed May 09, 2012 9:35 pmby KCStudly

Ah ha, now I see it. So without the extra depth, then the foam core goes away and we're back to Ply laminated on to the sides of lumber... or just lumber by it's self.

That still means cutting twice as many rib shape pieces of ply as there are ribs.

I think my next move will be to do a detailed layout of the ribs and see what size plank would work for the arcs and how many miter joints would be necessary.

Part of me wants to do the laminated lay up just for the cool factor and I think it would look cool,too, being as how I intend for the ribs to be exposed. It might just be the quickest and easiest method, so long as I can rip the slats cleanly and w/o too much trouble. Do the galley wall caps and hatch ribs all using the same jig and technique, production line style to gain efficiency.