Page 1 of 2

FLOOR DECKING/RIBBING - OAK VS. POPLAR

Posted:

Wed Sep 21, 2005 6:09 pmby demtears

I'm ready to start construction on the floor of my tear, but after a trip to my local Home Depot, I'm left with a bit of a problem. I wanted to use poplar,as it is one of the softest hardwoods, however, in my area it is only available in 8 foot lengths and I'm building a ten foot tear. Would oak be too hard or brittle to handle the wear and tear of a road trip?

Posted:

Wed Sep 21, 2005 6:32 pmby WarPony

From what I've seen on this site, oak or poplar is probably overkill for the floor. What is your layout for the floor? Maybe I don't understand what your plan of attack is going to be.

Posted:

Wed Sep 21, 2005 6:43 pmby Gage

For my floor, I used the cheapest piece of 1/2"x8' ply I could find and then added a 2' piece to it. I then covered the floor with vinyl tiles. Worked great.

Just the way I did it. Have a good day.

Posted:

Wed Sep 21, 2005 7:21 pmby demtears

The main floor will be 1/2 inch ply, but the cross ribbing or braces I wanted to go with poplar. as seen on Michael W's tear.

www.westhoffdesign.com/michael/teardrop ... ame2-l.gif

Posted:

Wed Sep 21, 2005 9:31 pmby Gage

Aw, I misunderstood your question. Sorry about that. What I did was run them lenght ways. I used high grade 2x6x10 pine (hand picked and very straight) and cut them to 2" strips. My floor sits down on the main frame and the 2" runners. Just the way I did it and have had no problems.

Hope that helps, have a good day.

Hope that helps, have a good day.

Posted:

Wed Sep 21, 2005 9:43 pmby vinoscooter

I think what your talking about is what they call on here as...The sub floor frameing...If you need to extend 8 foot to 10 you might want to use a Half Lap joint..

http://www.sawdustmaking.com/About%20Jo ... joints.htm

Ive seen others use it on the forum for the sub floor...It'll give a solid joint for sure...Maybe use it w/ 2 5ft length's...joint in the middle...After it's all glued, screwed,& bolted to the frame...Don't worry it'll be solid...

http://www.sawdustmaking.com/index.htm# ... nformation

http://www.sawdustmaking.com/index.htm# ... nformation

Good basic info here....scroll down to see the lap joints.. on the top link.The bottom link is the home page..There's different ways to extend 8 ft into a 10 footer..this is just one way to do it..vinoscooter

Posted:

Wed Sep 21, 2005 10:38 pmby Roly Nelson

My first woody tear has a 3/8" plywood floor, since you can't concentrate any heavy loads in just one place. That is what a mattress is for, it spreads out the load, no matter how heavy. With this mis-guided thinking, I built the second one with only a 1 3/8" hollow core door for the floor. Time will tell if I screwed up. So far so good. Right now, with the doors and hatchlid in place, it still weighs less than 250 lbs. Whew!

Roly, ~~

Posted:

Wed Sep 21, 2005 10:59 pmby Gage

Roly Nelson wrote:Right now, with the doors and hatchlid in place, it still weighs less than 250 lbs. Whew!

Roly, ~~

Roly, are you planning on pulling it or carrying it.

Have a good day.

floor framing

Posted:

Thu Sep 22, 2005 5:20 amby jay

poplar is not a moisture tolerant species.....

Posted:

Thu Sep 22, 2005 6:22 amby Geron

Just get some good straight pine 2x2's (hand picked). Yellow pine is still over kill for the floor framing. Soft white pine should be just fine. The floor frame coupled to the plywood flooring gives excellent strength since you'll probably be using at least 1/2" plywood. I've tried ripping 2x2's from larger timbers and have run into problems of warping, twisting, and curling.

For ribbing (spars) I'd go with yellow pine rather than white wood. It's just a bit stronger. For the Hatch hinge spars (on both the hatch and tear) use doubled spars of oak just to be safe. Worked for me -- so far.

Geron

Posted:

Thu Sep 22, 2005 6:35 amby demtears

Thank's for the advice guy's! next stop....... home depot!

Posted:

Thu Sep 22, 2005 6:42 amby Marck

Since all of the 2x2 pine at my local HD we buggered and knotty, I bought a 10' 2x12 pine and ripped it down to make 2x2.

It may not be fun, but it's not as bad as ripping the 2x12 s down for the stripping

Posted:

Thu Sep 22, 2005 7:06 amby Geron

demtears wrote:Thank's for the advice guy's! next stop....... home depot!

An addendum:

As for the floor framing - not to worry too much -- you're going to bolt the whole thing to a metal chassis. Just make SURE it's SQUARE and LEVEL. This is absolutely essential or you'll be pulling your hair out later on.

Like I said: SQUARE and LEVEL. If your garage (building/ground) floor is not level, use adjustable jack stands. But GET IT SQUARE AND LEVEL. Did I say Square and Level??

g

Posted:

Thu Sep 22, 2005 7:21 amby demtears

Geron wrote:demtears wrote:Thank's for the advice guy's! next stop....... home depot!

An addendum:

As for the floor framing - not to worry too much -- you're going to bolt the whole thing to a metal chassis. Just make SURE it's SQUARE and LEVEL. This is absolutely essential or you'll be pulling your hair out later on.

Like I said: SQUARE and LEVEL. If your garage (building/ground) floor is not level, use adjustable jack stands. But GET IT SQUARE AND LEVEL. Did I say Square and Level??

g

Square and level I think that's what you said! would you build from frame up, or if you could would you build it like asianflava did. It look's like he built his tear then installed it on the frame just wondering which would be the best way!

Posted:

Thu Sep 22, 2005 9:47 amby TRAIL-OF-TEARS

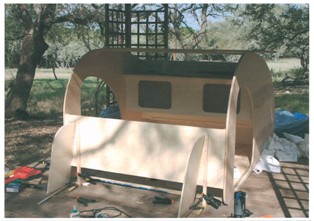

I built the body then put it on my frame (I moved the body onto the frame by myself). I have no sub floor and I use 1/2" cdx for the floor. I did use 1x2 poplar for the roof spars.