Bogo wrote:The 6061-T6 has a similar yield strength to the mild steel mentioned in the tongue strength page.

Beware. The problem with designing an aluminium frame is not its ultimate strength but its fatigue strength. Steel, especially mild steel, has the wonderful property of a 'fatigue limit'

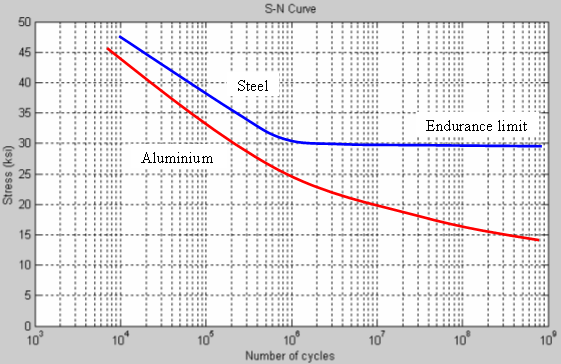

For the techs amongst you, here is a graph from Wikipedia comparing steel and typical aluminiums - except it calls is an 'endurance limit'.

Typically for steels, the fatigue limit (where the blue line levels out) is around 2/3rds its yield stress or around 1/2 its ultimate stress. What this means is that as long as you don't continually stress the steel beyond that percentage of its maximum strength, it will last forever without cracking.

For aluminium there is usually no fatigue limit and so eventually even quite low stresses will cause cracking. This means that even really light loads, like the 'thrumming' vibration you get driving on ribbed concrete, are eating away at the lifetime of an aluminium frame.

Now, if an aluminium frame lasts 100 years, then who cares if it cracks. But if it cracks after one year, that's a problem. The difficulty for the amateur frame builder is getting this difference right, as the 100-year frame may be only 50% stronger than the 1-year frame. For commercial builders, this isn't a big issue, as they have experience of making many frames over a long period, so they know what works.

For the amateur, the only way that I can see to make a safe aluminium frame that will last for years is to make it really strong - but then it won't weigh much less than a steel one and will probably cost more. So why bother?

Oh, and incidentally, it is the lack of a fatigue limit that means modern aluminium aircraft can't last forever - higher-strength aluminium alloys are particularly susceptible to fatigue cracking and so eventually the whole airframe has to be withdrawn from service. DC3s were made from earlier weaker alloys that didn't have such a fatigue problem, so they can fly pretty much forever - but they are heavy and fuel-inefficient as a result. I mention this just in case anyone wanted to say "they don't build them like the used to".......