Page 1 of 2

Angle Iron Frame Question

Posted:

Wed Oct 12, 2005 10:43 amby toypusher

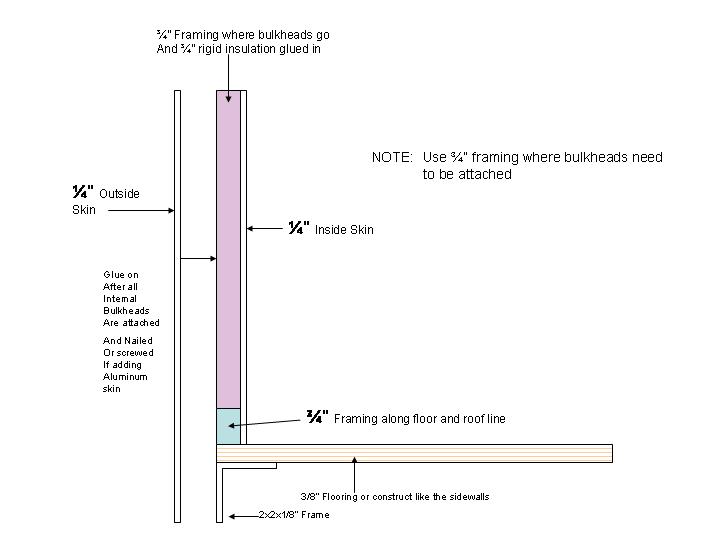

I am planning on building a 5x9 frame out of angle iron and was trying to figure the best way to attach the teardrop and also cover the frame without losing interior height. I want to keep the overall height at 4ft. Here is a drawing of how I was thinking to do it. The drawing shows bolts, but some of them would probably be just screws (like to fasten the floor down.)

NOTE:

Drawing not to scale

Also, for all you guys that have the frame hidden, how did you treat the front and back?

Posted:

Wed Oct 12, 2005 11:23 amby Geron

toypusher,

Looks like it would work to me. With the angle flat down instead of up you've lost only 1/8 in. in interior height and covered the frame.

I like it.

BTW that's the way the Tractor supply 4x8 trailer comes assembled from what I could see.

Geron

Posted:

Wed Oct 12, 2005 11:24 amby Chris C

Kerry,

That's basically what I've planned to do on my build, so I agree with you.

Posted:

Wed Oct 12, 2005 12:08 pmby Arne

Looks good, I like covering the frame as well....

Posted:

Wed Oct 12, 2005 2:26 pmby Gerdo

I thought of the same thing. I toyed with the thought of the angle the way you have it, or flipping it so the top had the flat return of the angle. I'm not sure if there is a structual advantage to either but if you had the flat up you could bolt directly to it without a filler block. I couldn't make up my mind. I had someone fabricate my frame and he wanted to use either "C" channel or square tubing, we went square tubing. More surface area to weld making it more rigid. I own a 5x10 utility trailer made out of angle (flat side down) with a 12" high railing also made out of angle, the deck is expanded steel. It is pretty flexible from corner to corner. After I had my Tear frame made it was totaly solid with no flex. Granted, by the time we build a Teardrop on top that is where a ton of the strength comes from.

Re: Angle Iron Frame Question

Posted:

Wed Oct 12, 2005 3:19 pmby mikeschn

Kerry,

I like your frame ideas... the filler block takes care of things wonderfully.

As for hiding the front and the back of the frame, it's easy enough... You bring the front skin down to the tongue, and you install a rear skin from the floor down to the frame.

I've looked at that close up in the cad program, and it works... I'll have to take a couple screen shots for you... If you haven't seen anything by Sunday morning, send me a reminder!

Mike...

toypusher wrote:I am planning on building a 5x9 frame out of angle iron and was trying to figure the best way to attach the teardrop and also cover the frame without losing interior height. I want to keep the overall height at 4ft. Here is a drawing of how I was thinking to do it. The drawing shows bolts, but some of them would probably be just screws (like to fasten the floor down.)

NOTE:

Drawing not to scale

Also, for all you guys that have the frame hidden, how did you treat the front and back?

Posted:

Wed Oct 12, 2005 3:27 pmby toypusher

Mike.

Thanks, I will be out of town from Sat morning until Tue evening. (going to see my dad in upstate NY for his 97th birthday).

How did you waterproof under the skin that is over the actual frame? Did you use asphalt emulsion or something on the inside? Or did you just use polyurethene glue along the bottom edge to create a good seal?

Posted:

Wed Oct 12, 2005 4:02 pmby mikeschn

Well seeing as it's only a computerized model, neither...

But the rear piece is easy enough to seal from the elements... roof tar on the inside, and paint on the outside.

The front part is a little tougher... You've got to figure out what is exposed, and then seal the inside with roof tar, then paint the outside and the edges with uniflex....

It's actually easier to do than it is to describe!

Mike...

Posted:

Thu Oct 13, 2005 11:44 pmby doug hodder

Not to be devils advocate here...but if you flopped the angle so that you had a flat surface for the deck to lay on, wouldn't it allow the water to drain out better and not get trapped between the wood filler block and the iron?...I would think it might minimize wood rot regardless of how it was sealed....and you will still have the flat iron on the exterior...at the point of axle attachment...you could just box the angle with another piece of angle making it 2x2 tube....for through bolting, just back up with a hefty washer....I'm thinking about an angle frame for the next one...had good luck building them in angle for motorcycles years ago....Just my thoughts on it.....Doug

Posted:

Fri Oct 14, 2005 12:10 amby madjack

doug hodder wrote:Not to be devils advocate here...but if you flopped the angle so that you had a flat surface for the deck to lay on, wouldn't it allow the water to drain out better and not get trapped between the wood filler block and the iron?...I would think it might minimize wood rot....and you will still have the flat iron on the exterior...at the point of axle attachment...you could just box the angle with another piece of angle making it 2x2 tube....for through bolting, just back up with a hefty washer....I'm thinking about an angle frame for the next one...had good luck building them in angle for motorcycles years ago....Just my thoughts on it.....Doug

...yeah, what you just said...that's is my thought for a frame for the NEXT one

madjack

Posted:

Fri Oct 14, 2005 2:28 amby mikeschn

toypusher wrote:Mike.

How did you waterproof under the skin that is over the actual frame? Did you use asphalt emulsion or something on the inside? Or did you just use polyurethene glue along the bottom edge to create a good seal?

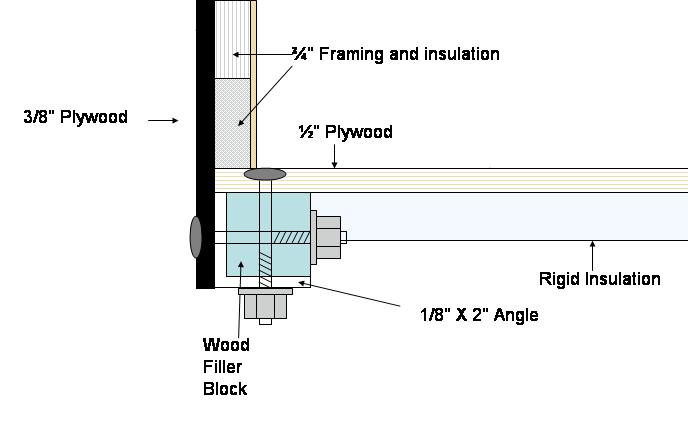

Kerry,

Here are screenshots of the front and rear frame coverings. You could seal them with anything that makes it truely waterproof. Epoxy resin, CPES, or roofing tar for example...

Mike...

Posted:

Fri Oct 14, 2005 5:36 amby BufordT

madjack wrote:doug hodder wrote:Not to be devils advocate here...but if you flopped the angle so that you had a flat surface for the deck to lay on, wouldn't it allow the water to drain out better and not get trapped between the wood filler block and the iron?...I would think it might minimize wood rot....and you will still have the flat iron on the exterior...at the point of axle attachment...you could just box the angle with another piece of angle making it 2x2 tube....for through bolting, just back up with a hefty washer....I'm thinking about an angle frame for the next one...had good luck building them in angle for motorcycles years ago....Just my thoughts on it.....Doug

...yeah, what you just said...that's is my thought for a frame for the NEXT one

madjack

These two guys have got it right. Check with someone on the board who has an original Benroy and ask how the frame was done. Mr. Ben and Mr. Roy had the angle flat. Then attached the sides over the angle as they came over. Those old timers sure did know what they were doing. And guess what they didn't overbuild.

Bufordt

Posted:

Fri Oct 14, 2005 5:44 amby Geron

BufordT wrote:madjack wrote:doug hodder wrote:Not to be devils advocate here...but if you flopped the angle so that you had a flat surface for the deck to lay on, wouldn't it allow the water to drain out better and not get trapped between the wood filler block and the iron?...I would think it might minimize wood rot....and you will still have the flat iron on the exterior...at the point of axle attachment...you could just box the angle with another piece of angle making it 2x2 tube....for through bolting, just back up with a hefty washer....I'm thinking about an angle frame for the next one...had good luck building them in angle for motorcycles years ago....Just my thoughts on it.....Doug

...yeah, what you just said...that's is my thought for a frame for the NEXT one

madjack

These two guys have got it right. Check with someone on the board who has an original Benroy and ask how the frame was done. Mr. Ben and Mr. Roy had the angle flat. Then attached the sides over the angle as they came over. Those old timers sure did know what they were doing. And guess what they didn't overbuild.

Bufordt

Could you draw a pic of what you just said. I'am a visual learner.

Geron

Posted:

Fri Oct 14, 2005 6:15 amby BufordT

You already did one toypusher. Look here.

http://tnttt.com/viewto ... &view=next

Bufordt

Posted:

Fri Oct 14, 2005 6:40 amby toypusher

Thanks Bufordt,

Here is is again for the those who would be visualization challenged