I would use a sanding sealer on the face that will show, to allow a more even penetration of stain.

Pine, stained without any sealer, can be very blotchy unless it is clear Pine...unlikely at the box store.

I like Danish oil products, as I can mix different colors to get the look I want. You can of course mix other types of stain for the same result.

The best (only way for me) is to make a sample board of the material you will be using, mark it off in sections

at least 6" x 6" with a pencil or sharpie, then try each color, or mixture of stain until you get the color you like.

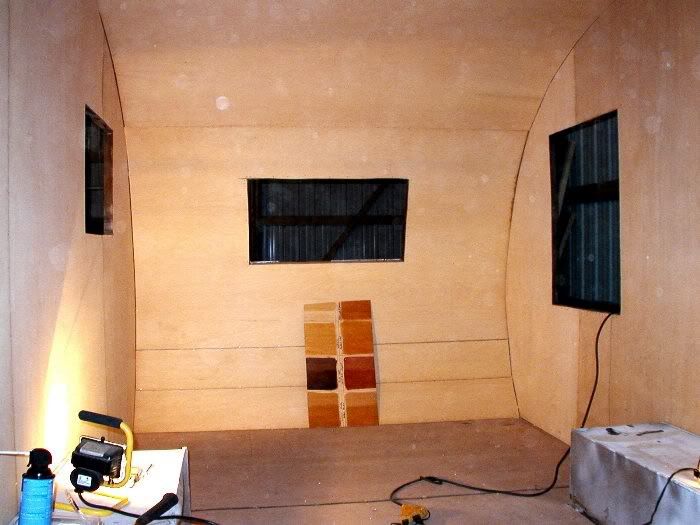

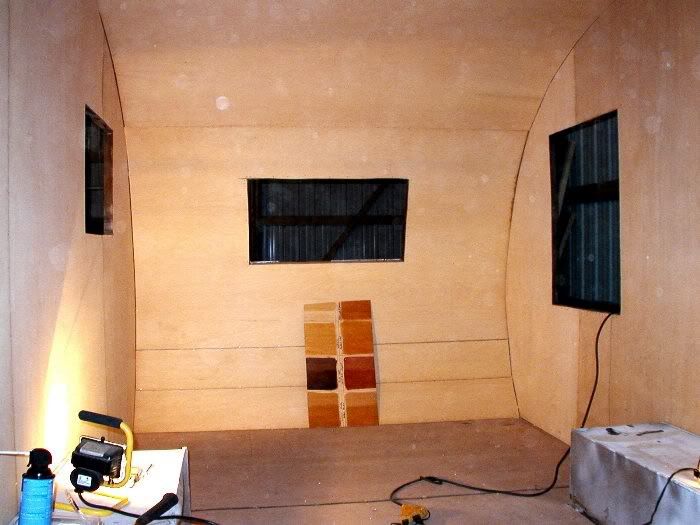

Here are a couple pictures that show the sample board, and the results of taking the time to get it right.

Keep in mind that clear, non yellowing polyurethane will darken it a little more, and some types of "clear" finish can darken it by several shades.

Point is, it will have a protective finish when done, so use that same finish on your sample board, over the stain.

Note the sample board; there are 8 different color areas.

One is natural, no stain, just varnish, and the others are different shades of stain.

The lighter, and darker areas within each color are the difference between stain, and stain covered with varnish.

I would also seal all sides and edges as Bob suggests, and though it is not as thrifty, it is good practice to use the same material, and the same number of coats to keep things "even".

Rob