Aniline dye and epoxy test panels

In my search for the perfect wood and finish for the outside of my woody teardrop I went through a variety of options: birch, oak, veneers. None of them allowed for a beautiful dark finish, even staining, nice grain, water resistance, and thin enough to bend to the curves of the profile. After lurking on some boat building forums I was suprised to come across the name of our very own Doug Hodder and his beautiful finishing work on his handcrafted boats. I talked with Doug (thanks Doug!), and I was pretty much convinced to go the route of Okoume marine plywood and aniline dye under epoxy and varnish.

I luckily found the Okoume plywood in Colorado and decided to test a couple aniline dyes. In my research I wasn't able to find a lot of examples so I thought I could post my results here and maybe help some others who might find themselves in the same situation.

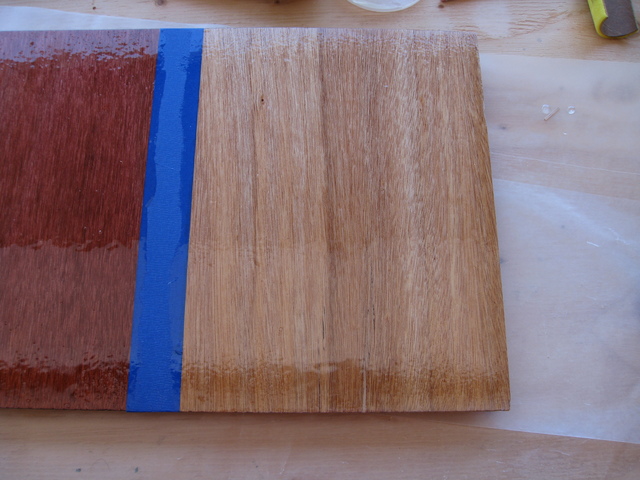

The Okoume marine plywood. The grain sold me but the color is very nice as well. This plywood is 4mm thick and bends well across the grain.

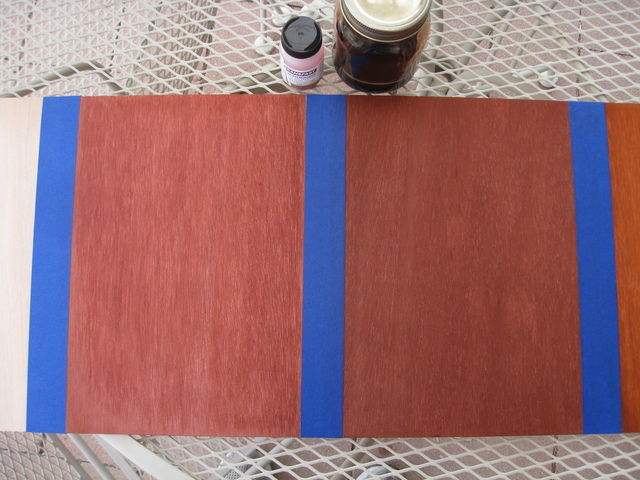

Okoume, sanded to 220 grit.

I used 2 different dyes in different concentrations:

Transfast: Dark Red Mohagany from Woodcraft

J.E. Mosers: Dark Colonial Red Mohagany from Woodworkers Supply

Okoume with no stain, not bad by itself!

Transfast panels. To the right is the recommended concentration which was let sit for a couple minutes then the excess was wiped clean with a dry rag. The left is the same but wiped with a damp rag, this pulls up some of the dye and makes it appear lighter. Do to the nature of aniline dye you can lighten with this method or darken by adding more dye to easily balance the color of large sections.

Same as above but with the J. E. Mosers dye.

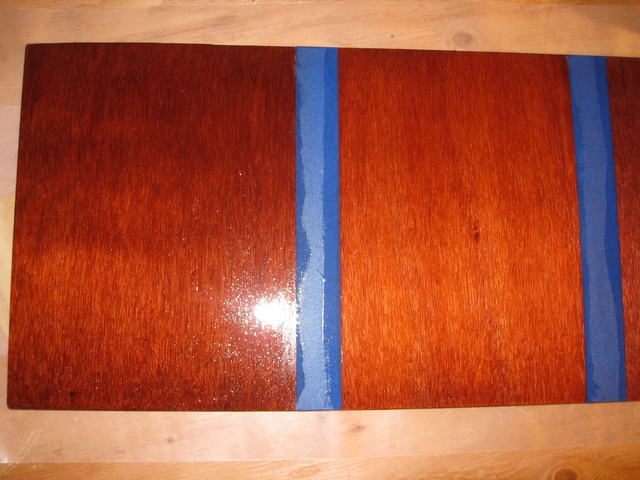

First layer of Epoxy, under artificial light.

Transfast

J.E. Mosers

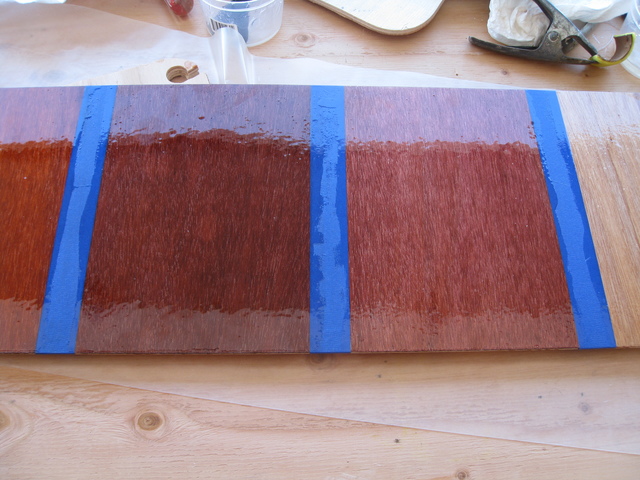

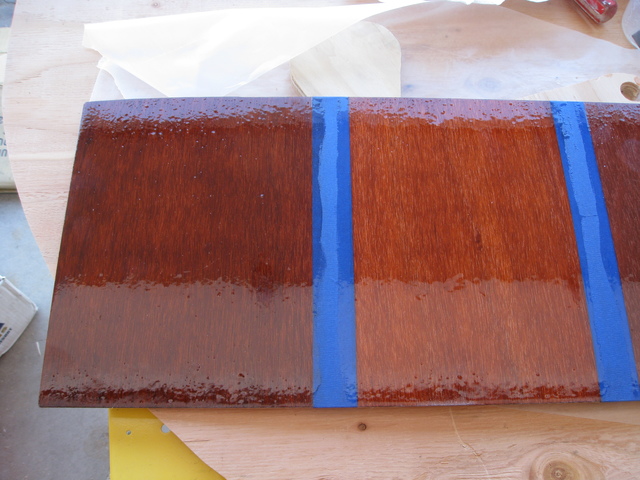

Second coat under natural light. I put the second coat on after about 3 hours. I wasn't too careful about the dust and air bubbles which are apparent in these pictures, I tried to get an angle that would maximize the gloss of the finish.

Transfast

J.E. Mosers

The outcome of these tests were pretty amazing. The combination of Okoume, aniline dye, and epoxy was exactly what I was looking for! After the tests I'm definitely leaning toward the J.E. Mosers dye, somewhere in between the two darkness levels in these tests.

I luckily found the Okoume plywood in Colorado and decided to test a couple aniline dyes. In my research I wasn't able to find a lot of examples so I thought I could post my results here and maybe help some others who might find themselves in the same situation.

The Okoume marine plywood. The grain sold me but the color is very nice as well. This plywood is 4mm thick and bends well across the grain.

Okoume, sanded to 220 grit.

I used 2 different dyes in different concentrations:

Transfast: Dark Red Mohagany from Woodcraft

J.E. Mosers: Dark Colonial Red Mohagany from Woodworkers Supply

Okoume with no stain, not bad by itself!

Transfast panels. To the right is the recommended concentration which was let sit for a couple minutes then the excess was wiped clean with a dry rag. The left is the same but wiped with a damp rag, this pulls up some of the dye and makes it appear lighter. Do to the nature of aniline dye you can lighten with this method or darken by adding more dye to easily balance the color of large sections.

Same as above but with the J. E. Mosers dye.

First layer of Epoxy, under artificial light.

Transfast

J.E. Mosers

Second coat under natural light. I put the second coat on after about 3 hours. I wasn't too careful about the dust and air bubbles which are apparent in these pictures, I tried to get an angle that would maximize the gloss of the finish.

Transfast

J.E. Mosers

The outcome of these tests were pretty amazing. The combination of Okoume, aniline dye, and epoxy was exactly what I was looking for! After the tests I'm definitely leaning toward the J.E. Mosers dye, somewhere in between the two darkness levels in these tests.