Page 1 of 1

Aluminum vs Steel

Posted:

Fri Aug 09, 2013 9:51 pmby jonesnforcampin

We are planning on building a 5x10 camper on a 5x8 NT trailer, I think I'm going a little unorthodox on it so I'm looking for input on materials. I'm planning on making the camper removable so the floor needs to be REALLY strong. I'm thinking of using 1"x2" tube steel down both sides and 3/4"x 3/4" tube steel as ribs. I'm gonna weld this all together and then put 1/2" plywood underneath and 1/2" plywood as an inside floor between the two side rails.

Then for my rib pieces in my roof I'm planning on using 3/4" x 3/4" tube with flat bar on the ends making an "I" shape and bolting my walls to the flat bar.

Hope that makes sense...

So anyways... I had thought aluminum would be quite a bit more $$ than steel. But, after looking at it, it isn't really. My Dad is adamant that I use steel for my camper floor frame. But, I'm wondering if I would be ok on the roof to use aluminum to make the "I" ribs? I'm thinking cutting AL angle to make brackets and bolting them to AL tube. Then bolt the walls to the AL brackets that I cut out of the angle stock.

What do you folks think? Strong enough? Worth it? Could I do the same idea for the camper floor frame?

Re: Aluminum vs Steel

Posted:

Sat Aug 10, 2013 12:00 amby KCStudly

My friend Jeff (Grotto Jeff) made a very functional slide in camper out of 1x sq tube alum joined with 1x1x1/8 alum angle and TEK screws. Well, technically not a slide in because he built around the wheel wells. He skinned the whole thing in thin ply, IIRC luan underlay. I forget how he attached the skin and what he used for outer skin.

He hauled it from the east coast (NE) thru Alaska and back, and a couple trips to the outer banks of Carolina (IIRC).

It is viable.

His interior was not finished off, but it has sat thru several NE winters with several feet of snow and is still in decent shape.

Re: Aluminum vs Steel

Posted:

Sat Aug 10, 2013 12:37 amby RandyG

Dont count aluminum as the underdog, it has much more strength to weigh ratio than steel. If engineered and thoughtout enough, you can do it with Al and save alot of weight and keep the strength you need.

Re: Aluminum vs Steel

Posted:

Sat Aug 10, 2013 6:40 amby angib

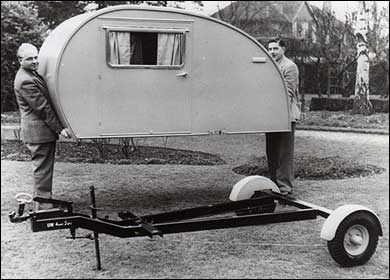

If you build to a sensible weight, I don't think you need any metal in the removable section. Good strong joints in plywood are strong enough as the body is a self-supporting box.

If this could be done 60 years ago, why not today?

- berkeley08.jpg (21.33 KiB) Viewed 952 times

Re: Aluminum vs Steel

Posted:

Sat Aug 10, 2013 3:12 pmby jonesnforcampin

angib wrote:If you build to a sensible weight, I don't think you need any metal in the removable section. Good strong joints in plywood are strong enough as the body is a self-supporting box.

If this could be done 60 years ago, why not today?

berkeley08.jpg

While I can't/won't argue your point, my camper is going to be quite a bit bigger than the one in the photo. Plus, not being 100% of the best joining teqniques for plywood I think erring on the side of overbuilding/caution would be prudent.

Re: Aluminum vs Steel

Posted:

Sat Aug 10, 2013 3:15 pmby jonesnforcampin

Thanks for the replies thus far.. I think I'm gonna contact the supplier I plan on using to see what the cost difference is on the AL side beams as well. That could save me a bunch of weight.

Re: Aluminum vs Steel

Posted:

Sat Aug 10, 2013 3:39 pmby RandyG

If you have access to a metal brake, you can make some Hat~channel from strips of sheet metal.

Re: Aluminum vs Steel

Posted:

Sat Aug 10, 2013 8:09 pmby aggie79

angib wrote:If you build to a sensible weight, I don't think you need any metal in the removable section. Good strong joints in plywood are strong enough as the body is a self-supporting box.

If this could be done 60 years ago, why not today?

berkeley08.jpg

Not lightweight, but plenty strong. The shell is 5' wide x 10' long x 4' tall.

The photos are with no cabinets, and no exterior plywood skins on the walls and roof. Floor is 1/4" plywood, 3/4" framing, and 1/4" plywood. Roof is 1/8" plywood and 1x2 framing. Sidewall framing is 3/4" plywood with 3/16" engineered flooring for the interior skin.