doug hodder wrote:Ron, before you install the plexi, make sure that the openings into the wood are very well sealed with an epoxy so that you get no water penetration into the window opening grain. Once the plex is installed, it's going to be next to impossible to deal that area as anything used to smooth out the wood opening will scratch up the plex if you get into it. I used an acrylic caulk on mine and was able to smooth out the bond squish with a wet finger, then let it cure. I used glass on my portholes however. Any slopped silicone can also cause painting issues, but an acrylic can take the paint. FWIW Doug

thank you doug and rowerwe for your answers.

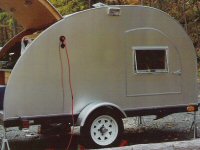

As you can see the trolley is painted around the windows and upper side, where the plexi. will be layed.

What I am doing I have never done. so it would seem I do not know what I am doing, but somewhere in my past I have been exposed to it.

So far I have cut out the plexi. drilled holes in it where I would put small brass wood screws.

MY Plan to

I had planned to put the silicone around the window openings screw down the wood screws, then put more silicone along the outer edge of the plexiglass cut out and run a finger or object along the edge to angle it some (wiping up the extra as I went with that isopropyl alchohol, you suggested) put little dabs where the screws or in the screw holes before drilling.

Doug suggests acrylic caulk with the isopropyl alchohol work on that too? Each panel has will have 8 scews.

will my idea work or am I in for a world of hurt.

Ron