Wall to ceiling roundover

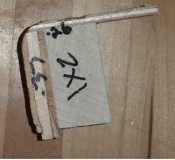

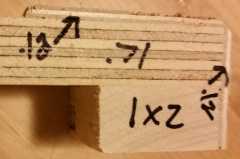

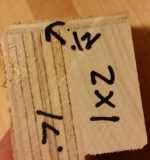

When building my trailer i used a 1/2 inch roundover so that i could use fiberglass tape. So i took different sizes of baltic birch plywood to see the profile at different wall thicknesses. the roof panel was .12 inch baltic birch and to simulate spars i used 1x2 poplar. the different wall thickness in inches are .71 .46 and .37. i used liquid nails as the adhesive. once the panels had set i ran them on my router table with a 1/2 inch roundover router bit.

at .37 there was a gluing surface of .26 left over.

at .46 there was a gluing surface of .37 left over.

at .71 there was a gluing surface of .63 left over.

so on average you lose about .09 inches of material from the .12 roof panel

any strength you lose from plywood joint would be more than compensated by using fiberglass tape to reinforce.

took in account for a .71 interior and a .12 exterior with a .12 roof. same 1/2 inch roundover many of the cookie cutter profiles use this setup.

at .37 there was a gluing surface of .26 left over.

at .46 there was a gluing surface of .37 left over.

at .71 there was a gluing surface of .63 left over.

so on average you lose about .09 inches of material from the .12 roof panel

any strength you lose from plywood joint would be more than compensated by using fiberglass tape to reinforce.

took in account for a .71 interior and a .12 exterior with a .12 roof. same 1/2 inch roundover many of the cookie cutter profiles use this setup.