What's the appeal of a fredrick galley hatch?

All,

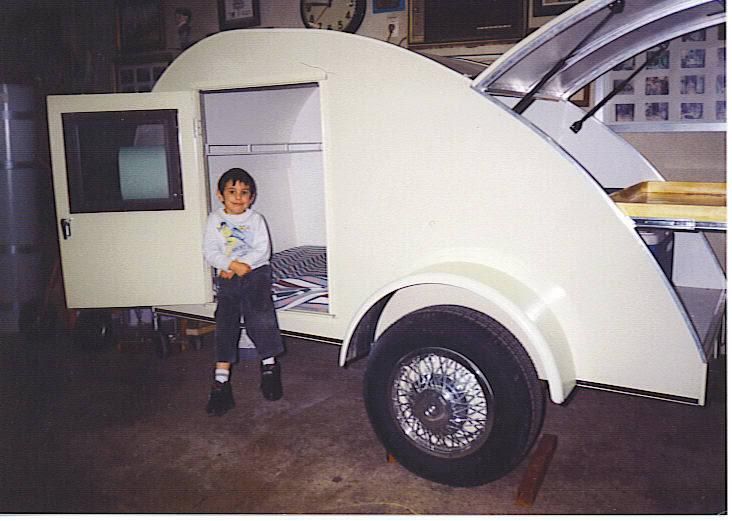

I'm well on my way to constructing my tear I'll go and pick up the trailer I'm having made in two weeks. One of the last details I'm trying to work out is how I'm going to do the hatch. So far I've seen three predominate styles.

-The original style. A quarter inch is taken away from the galley sides to make room for a seal. Two inch aluminum angle goes over the hatch lid and rests against the sides of the camper. A seal goes underneath the angle. Flat strip molding is applied to the top edges of the galley sides.

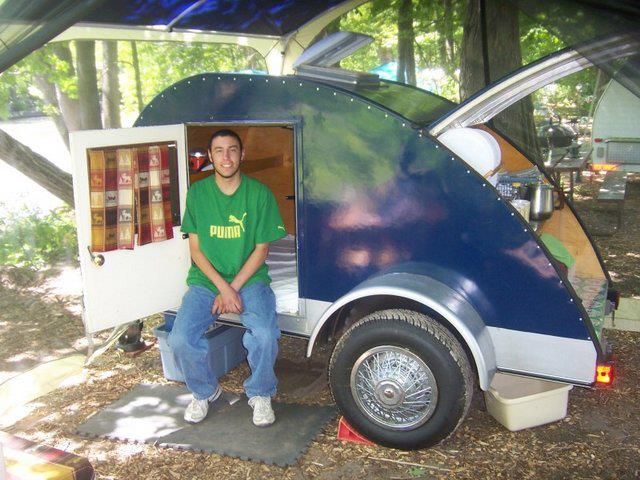

-The fredrick style which is getting more popular. About six inches are dug out of the galley sides to make room for beefy side brackets on the sides of the galley lid. Inside the galley walls 1'/4" plywood is attached such that it goes an inch above the outer galley walls and rests inside slots in the galley lid.

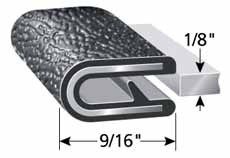

-The third style seems to make a galley lid slightly smaller than the width of the trailer and use T molding with a seal on all sides. This seems to be the popular option for manufacturers these days.

So here is my question. The original design seems to me like it would provide the greatest longevity because water does not contact as much wood. from the outside going in there is an immediate sandwich of aluminum trim, angle, and a rubber seal. When the camper is at rest water cannot even contact the seam between the lid and the sides. The only weakness I see is that when the camper towed in the rain the angle could grab the water that runs back over the sides and push it toward the seal.

With the fredrick hatch design, water coming from the outside would get pulled between the two peices of trim (one on top and one on bottom) and come to rest against the 1/4 plywood (notch/seal). So water is always resting against wood in this design? I realize that we seal everything with epoxy but it still seems less than ideal. At the same time I can see the appeal of the added weight to the lid.

I haven't really given any thought to the third design other than to scratch my head and wonder if it's simply more aesthetic than the original design. It seems like water would more readily enter the seal both in motion and at rest.

Can someone comment on these design choices and refute any of my suppositions. I really would like to figure out what I'm going to do on my build.

Thanks!

I'm well on my way to constructing my tear I'll go and pick up the trailer I'm having made in two weeks. One of the last details I'm trying to work out is how I'm going to do the hatch. So far I've seen three predominate styles.

-The original style. A quarter inch is taken away from the galley sides to make room for a seal. Two inch aluminum angle goes over the hatch lid and rests against the sides of the camper. A seal goes underneath the angle. Flat strip molding is applied to the top edges of the galley sides.

-The fredrick style which is getting more popular. About six inches are dug out of the galley sides to make room for beefy side brackets on the sides of the galley lid. Inside the galley walls 1'/4" plywood is attached such that it goes an inch above the outer galley walls and rests inside slots in the galley lid.

-The third style seems to make a galley lid slightly smaller than the width of the trailer and use T molding with a seal on all sides. This seems to be the popular option for manufacturers these days.

So here is my question. The original design seems to me like it would provide the greatest longevity because water does not contact as much wood. from the outside going in there is an immediate sandwich of aluminum trim, angle, and a rubber seal. When the camper is at rest water cannot even contact the seam between the lid and the sides. The only weakness I see is that when the camper towed in the rain the angle could grab the water that runs back over the sides and push it toward the seal.

With the fredrick hatch design, water coming from the outside would get pulled between the two peices of trim (one on top and one on bottom) and come to rest against the 1/4 plywood (notch/seal). So water is always resting against wood in this design? I realize that we seal everything with epoxy but it still seems less than ideal. At the same time I can see the appeal of the added weight to the lid.

I haven't really given any thought to the third design other than to scratch my head and wonder if it's simply more aesthetic than the original design. It seems like water would more readily enter the seal both in motion and at rest.

Can someone comment on these design choices and refute any of my suppositions. I really would like to figure out what I'm going to do on my build.

Thanks!