Don:

I've built a 5x10, a 4x8, and am working on another 5x10. I've found that the first thing I do, that really helps me, is to build a pattern out of 1/4" plywood. It's got the door cutout, the bulkhead locations marked, the locations for any hard spots that will need internal support. And then draw the skeleton on it and mark the corners with 1/8" holes so I can transfer the skeleton plan to the plywood that I'm using for the internal structure. For me, that pattern is a great tool to have throughout the build process. (Yes, it's a bit of a pain in the butt to make a 4x10' piece of plywood for the pattern, but it's well worth the time and expense.)

I've used 3/4" pine for the skeleton, 3/4" AC plywood (I hate CDX), and 1/2" AC plywood. The plywood is quicker. You can clamp both sides together and "gang" cut them. Works fine. I probably over build keeping the structural width of the internals 2-3.5" depending on what it's purpose is.

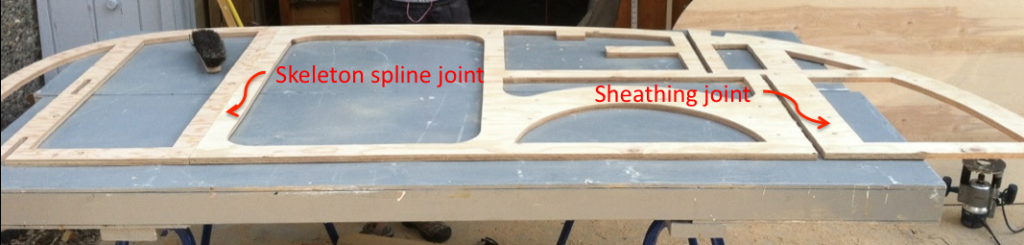

There's two inches that will be cut off this wall since I use the Fredrick's hatch method, so you can (probably?) disregard the fact that there's 4" of structural material at the rear. This wall has supports for an extra shelf for a CPAP machine and and shore power:

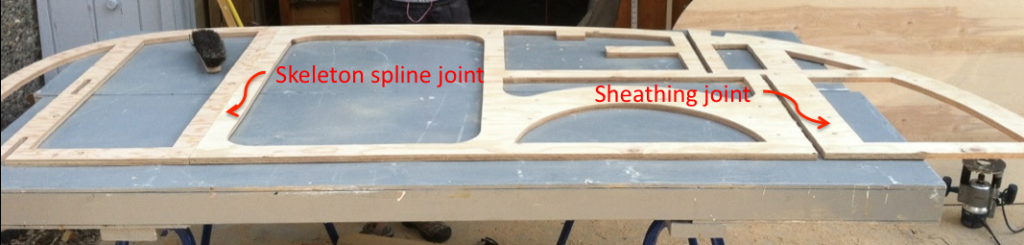

I put the text on this pic for another post, but I think you can get the idea on how things are laid out to support the (mortised) bulkheads, doors, shelves etc.

Rule of thumb? I'll be curious to hear if there's a standard practise for this.

Tony