Hatch Struts...Formula?

Hi all,

Trying to figure out what size struts I need without having to drill 20 different holes, and try 10 different struts...guess I should have paid more attention in math class

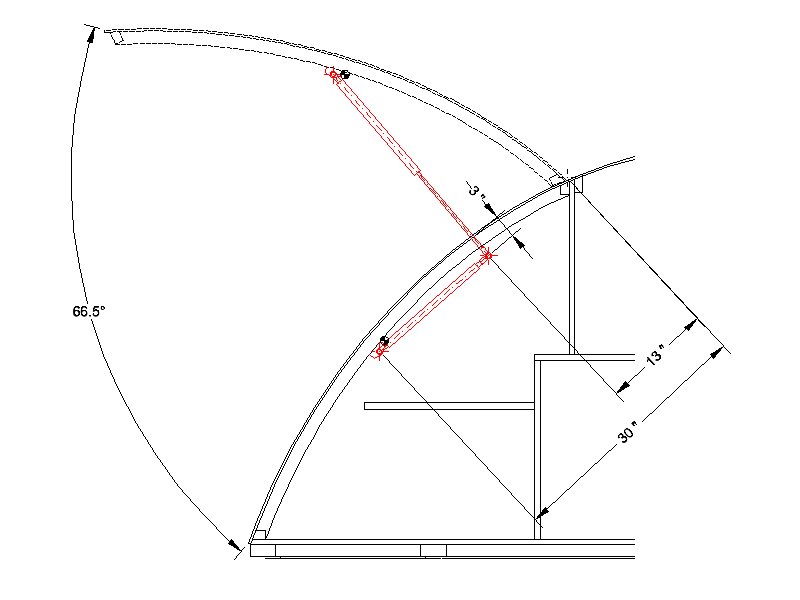

This drawing was posted by Andrew,

I've been studying it, but haven't found the common denominator (if there is one) that I can use to apply to my hatch size.

Is there a formula?

Rob

Trying to figure out what size struts I need without having to drill 20 different holes, and try 10 different struts...guess I should have paid more attention in math class

This drawing was posted by Andrew,

I've been studying it, but haven't found the common denominator (if there is one) that I can use to apply to my hatch size.

Is there a formula?

Rob

I started out in mechanical engineering but moved to computers instead.

I started out in mechanical engineering but moved to computers instead.

I just make sure to put mine about 6 to 8 inches from the pivot point, any further for me doesn't lift the hatch far enough. The only draw back from attaching them closer to the pivot point is you use a stronger gas shock. I have 150# on my first tear and 120# on my second.

I just make sure to put mine about 6 to 8 inches from the pivot point, any further for me doesn't lift the hatch far enough. The only draw back from attaching them closer to the pivot point is you use a stronger gas shock. I have 150# on my first tear and 120# on my second.