Bending Plywood for Hatch

Hello Everyone,

I already build the hatch frame. Now I'm at the point I need to bend the plywood over the frame. I am using a thickness that is less than 1/4" but a little thicker than 1/8". You know that now at the hardware stores they have all these measurements in MM. What ever happened to 1/8", 1/4" and so on? It's not a Benroy model but more of a teardrop radius. How can I bend it with out causing any spring back on my hatch or cracking the plywood? I have 6 ribs 3/4" thick and are 3" wide. That will avoid any spring back I hope. It's kind of hard to find good plywood so I went with the underlayment type plywood.

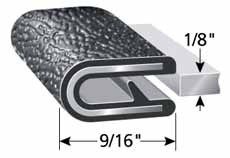

Now I need to find a hatch lock. I would like to use a lock with rods that go in to the side walls. Something like a garage door or a truck cap lock system.

Any suggestions on both issues will be helpful.

Thank you

Carlos

I already build the hatch frame. Now I'm at the point I need to bend the plywood over the frame. I am using a thickness that is less than 1/4" but a little thicker than 1/8". You know that now at the hardware stores they have all these measurements in MM. What ever happened to 1/8", 1/4" and so on? It's not a Benroy model but more of a teardrop radius. How can I bend it with out causing any spring back on my hatch or cracking the plywood? I have 6 ribs 3/4" thick and are 3" wide. That will avoid any spring back I hope. It's kind of hard to find good plywood so I went with the underlayment type plywood.

Now I need to find a hatch lock. I would like to use a lock with rods that go in to the side walls. Something like a garage door or a truck cap lock system.

Any suggestions on both issues will be helpful.

Thank you

Carlos

Danny

Danny