Page 1 of 2

Sealing my trim screws - 3M 5200 no good, too permanent???

Posted:

Mon Aug 20, 2018 3:38 pmby cfiiman

Hi everyone,

I finally got my teardrop skinned with aluminum and all my custom made trim moldings in place. I spent extra time and money sourcing a one piece aluminum roof for b/c I didn't want seams (more for water intrusion possibilities than looks). So basically I have a complete 1 piece shell to fight against water intrusion from the elements. The problem obviously is I now have put tons of stainless steel screws through that trim and into my camper

haha. Anyway I had read on here some time ago that some of you use the 3M 5200 sealant to fill the screw holes and then re-screw them in. I went an bought the 3m 5200 the other day (wow expensive haha) but now I'm hesitant b/c what if I ever wanted to remove the screws for any reason. I keep reading on boat forums that it is crazy difficult to get anything apart if used. I've already snapped off a few of the SS screw heads so I'm worried if I ever wanted to remove the screws, say if I needed to replace a piece of damaged skin or something, I'd snap all my screw heads off. I'm starting to think maybe just balling up a little piece of butyl tape and pushing into each hole might be better? Or maybe just plain DAP Dynaflex 230? I honestly like the thought of the strong bond though of the 5200 to help "hold" all the screws when you are talking about vibration from years of towing, etc. Also, then I think, I built this to be water tight and I don't ever want to take it apart again so why worry? I don't know, I'm just unsure of what to do, can anyone help guide me on the best course of action for sealing these screws? The camper turned out much better than I ever imagined and I'm really proud of it, don't want to mess something up when I can see the finish line. Thanks for any guidance.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 4:00 pmby working on it

Though I've no experience with trim screws on a "nice" teardrop, I used PL Premium adhesive to fill-in all the holes on my all-wood, no aluminum TTT, and hold the few trim pieces on...except for around my two windows. There, I used semi-flexible OSI Quad. I read that it remains flexible, though I haven't prodded it to see lately, but it was still flexible after two years (tested in 2014, two years after the window install). I do't see why it shouldn't work for trim, and must be easier to remove than 3M 5200, or Loctite PL Premium.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 4:17 pmby cfiiman

Hi thanks for the reply. The more I think about this, and the way my tear is built, the more I think "permanent but flexible" is the way to go like with the 5200. If I was ever to have to remove the aluminum, I''m thinking something catastrophic must have happened (physical damage, big water intrusion, etc.) If however I use something with a weaker bond and the vibration over time from trailering allows the screws or trim to become loose, that is when there would be a real danger of water intrusion in my mind. Now I built it with backup techniques to prevent even that, like the spar varnish, aluminum tape over ever staple/seam, but still I'm thinking this is a go for broke issue that 5200 seams perfect for the more I think about it. Who knows, maybe you could even get the screws out if you did use it I just wasn't sure. But I know that the screws holding the trim on are not huge screws and using an adhesive/sealant I think is the right move. PL Construction Adhesive is great, I used it a lot on my sheeting, but it dries very hard and brittle, which I don't think would be good for the screws in the aluminum trim. Regular caulk like Dynaflex 230 would work too, but it is only a sealant, no adhesive properties. Maybe I've answered my own question here, but guess just looking for reassurance it is a good course of action.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 4:34 pmby aggie79

I used the "less permanent" 3M 4200. It is removable but just barely.

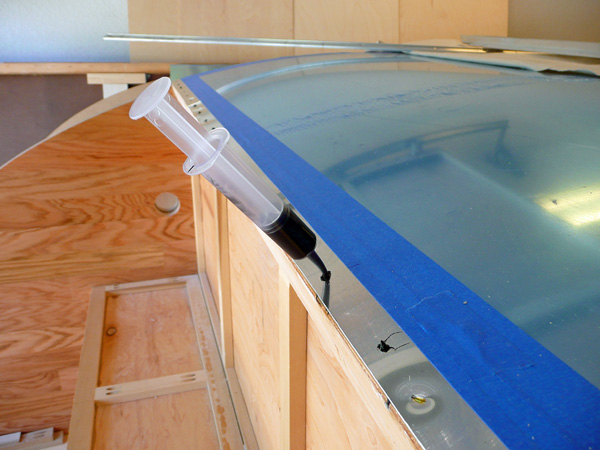

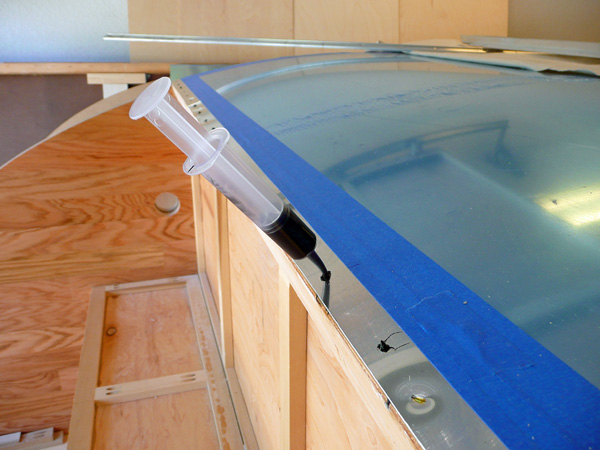

I used a two-part method for attaching my trim and skin. First, I temporarily attached trim & skin using regular Kreg screws but no 3M 4200. After attached, I replaced each one screw-by-screw with SS Kreg screws and injected 3M 4200 as I went along.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 4:45 pmby cfiiman

Ha, yes yours was the post I was remembering! So you used 4200 then. Do you think 5200 is a mistake for my screws? I"m not attaching the aluminum b/c there are no seams, this is simply to help seal and keep the screws in place over the years.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 6:31 pmby S. Heisley

aggie79 wrote:I used the "less permanent" 3M 4200. It is removable but just barely.

I used a two-part method for attaching my trim and skin. First, I temporarily attached trim & skin using regular Kreg screws but no 3M 4200. After attached, I replaced each one screw-by-screw with SS Kreg screws and injected 3M 4200 as I went along.

Tom is correct. 3M 4200 is less permanent. 3M 5200 is

very permanent and will tear your wood up if you try to undo it.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 6:57 pmby cfiiman

S. Heisley wrote:aggie79 wrote:I used the "less permanent" 3M 4200. It is removable but just barely.

I used a two-part method for attaching my trim and skin. First, I temporarily attached trim & skin using regular Kreg screws but no 3M 4200. After attached, I replaced each one screw-by-screw with SS Kreg screws and injected 3M 4200 as I went along.

Tom is correct. 3M 4200 is less permanent. 3M 5200 is

very permanent and will tear your wood up if you try to undo it.

Agreed, but isn't that what I want? For example, the luan plywood skin underneath is power grabbed and stapled a million times, so it would have to be "torn out" too, so it seems like the whole thing I built to be "permanent" really, for good or for bad. This is why I did so many things to the wood underneath, in hopes I never have to fix it. I don't know, I'm still thinking 5200 would be the best choice just a small dab in each screw hole, I want them to hold, but if 4200 will accomplish the same thing I can just order that and return the 5200. Does anyone think 5200 would be the better choice?

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 9:08 pmby Sparksalot

Golly, all I did was use RTV on them before driving the screws in.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 9:26 pmby GuitarPhotog

Sparksalot wrote:Golly, all I did was use RTV on them before driving the screws in.

You can expect them to leak sometime down the line. RTV is not rated for exterior use and eventually breaks down, leaving you with a leak. That's why most people recommend a polyurethane caulk like Trempro630 or SikaFlex or similar.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Mon Aug 20, 2018 10:06 pmby Sparksalot

Not an exterior application, I applied it to the threads. The wood itself was well soaked in CPES, and my baby is kept indoors except when camping. She's more than 10 years old.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Tue Aug 21, 2018 8:19 amby aggie79

I have...delicately...removed a few stainless steel screws with the 3M 4200 but did "snap" one in the process. Both the 4200 and 5200 are designed for below the waterline use. I think 5200 will work but depending upon how much you use and how long your fasteners are, you may not be able to remove them if you need to some day.

I love the 3M products, but in the "if I were to do it again" scenario, OSI gutter sealant will work just as well, is significantly less expensive, and is available at most the orange and blue big box stores.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Tue Aug 21, 2018 8:25 pmby DWT77

aggie79 wrote:I used the "less permanent" 3M 4200. It is removable but just barely.

I used a two-part method for attaching my trim and skin. First, I temporarily attached trim & skin using regular Kreg screws but no 3M 4200. After attached, I replaced each one screw-by-screw with SS Kreg screws and injected 3M 4200 as I went along.

Tom, I have some of the 4200 I was thinking of using around my doors/windows/vent fan. Did you do that as well?

or I was thinking of using Butyl tape around the doors/windows but then just put a bead of 4200 around the outside edge.

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Thu Aug 23, 2018 4:16 pmby aggie79

On my windows, I used butyl tape. On my vent fan, I used the foam gasket with a touch of latex sealant on either side of the sealant. In the fan screw holes around the raised edge of the fan, I used OSI Quad sealant. On door lock set, power inlet, taillights, market lights, and other “removable” miscellaneous hardware, I used a light bead of latex sealant.

Sent from my iPhone using Tapatalk

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Thu Aug 23, 2018 8:14 pmby DWT77

aggie79 wrote:On my windows, I used butyl tape. On my vent fan, I used the foam gasket with a touch of latex sealant on either side of the sealant. In the fan screw holes around the raised edge of the fan, I used OSI Quad sealant. On door lock set, power inlet, taillights, market lights, and other “removable” miscellaneous hardware, I used a light bead of latex sealant.

Sent from my iPhone using Tapatalk

Thanks Tom and definitely makes sense to use less permanent sealant on parts that could fail or possibly need to be removed in the future

Re: Sealing my trim screws - 3M 5200 no good, too permanent?

Posted:

Fri Aug 24, 2018 6:26 amby cfiiman

I've decided to take back the 5200 and go with the new 3M 4000UV to seal my screws per the recommendations here, thanks guys.

haha. Anyway I had read on here some time ago that some of you use the 3M 5200 sealant to fill the screw holes and then re-screw them in. I went an bought the 3m 5200 the other day (wow expensive haha) but now I'm hesitant b/c what if I ever wanted to remove the screws for any reason. I keep reading on boat forums that it is crazy difficult to get anything apart if used. I've already snapped off a few of the SS screw heads so I'm worried if I ever wanted to remove the screws, say if I needed to replace a piece of damaged skin or something, I'd snap all my screw heads off. I'm starting to think maybe just balling up a little piece of butyl tape and pushing into each hole might be better? Or maybe just plain DAP Dynaflex 230? I honestly like the thought of the strong bond though of the 5200 to help "hold" all the screws when you are talking about vibration from years of towing, etc. Also, then I think, I built this to be water tight and I don't ever want to take it apart again so why worry? I don't know, I'm just unsure of what to do, can anyone help guide me on the best course of action for sealing these screws? The camper turned out much better than I ever imagined and I'm really proud of it, don't want to mess something up when I can see the finish line. Thanks for any guidance.

haha. Anyway I had read on here some time ago that some of you use the 3M 5200 sealant to fill the screw holes and then re-screw them in. I went an bought the 3m 5200 the other day (wow expensive haha) but now I'm hesitant b/c what if I ever wanted to remove the screws for any reason. I keep reading on boat forums that it is crazy difficult to get anything apart if used. I've already snapped off a few of the SS screw heads so I'm worried if I ever wanted to remove the screws, say if I needed to replace a piece of damaged skin or something, I'd snap all my screw heads off. I'm starting to think maybe just balling up a little piece of butyl tape and pushing into each hole might be better? Or maybe just plain DAP Dynaflex 230? I honestly like the thought of the strong bond though of the 5200 to help "hold" all the screws when you are talking about vibration from years of towing, etc. Also, then I think, I built this to be water tight and I don't ever want to take it apart again so why worry? I don't know, I'm just unsure of what to do, can anyone help guide me on the best course of action for sealing these screws? The camper turned out much better than I ever imagined and I'm really proud of it, don't want to mess something up when I can see the finish line. Thanks for any guidance. haha. Anyway I had read on here some time ago that some of you use the 3M 5200 sealant to fill the screw holes and then re-screw them in. I went an bought the 3m 5200 the other day (wow expensive haha) but now I'm hesitant b/c what if I ever wanted to remove the screws for any reason. I keep reading on boat forums that it is crazy difficult to get anything apart if used. I've already snapped off a few of the SS screw heads so I'm worried if I ever wanted to remove the screws, say if I needed to replace a piece of damaged skin or something, I'd snap all my screw heads off. I'm starting to think maybe just balling up a little piece of butyl tape and pushing into each hole might be better? Or maybe just plain DAP Dynaflex 230? I honestly like the thought of the strong bond though of the 5200 to help "hold" all the screws when you are talking about vibration from years of towing, etc. Also, then I think, I built this to be water tight and I don't ever want to take it apart again so why worry? I don't know, I'm just unsure of what to do, can anyone help guide me on the best course of action for sealing these screws? The camper turned out much better than I ever imagined and I'm really proud of it, don't want to mess something up when I can see the finish line. Thanks for any guidance.

haha. Anyway I had read on here some time ago that some of you use the 3M 5200 sealant to fill the screw holes and then re-screw them in. I went an bought the 3m 5200 the other day (wow expensive haha) but now I'm hesitant b/c what if I ever wanted to remove the screws for any reason. I keep reading on boat forums that it is crazy difficult to get anything apart if used. I've already snapped off a few of the SS screw heads so I'm worried if I ever wanted to remove the screws, say if I needed to replace a piece of damaged skin or something, I'd snap all my screw heads off. I'm starting to think maybe just balling up a little piece of butyl tape and pushing into each hole might be better? Or maybe just plain DAP Dynaflex 230? I honestly like the thought of the strong bond though of the 5200 to help "hold" all the screws when you are talking about vibration from years of towing, etc. Also, then I think, I built this to be water tight and I don't ever want to take it apart again so why worry? I don't know, I'm just unsure of what to do, can anyone help guide me on the best course of action for sealing these screws? The camper turned out much better than I ever imagined and I'm really proud of it, don't want to mess something up when I can see the finish line. Thanks for any guidance.