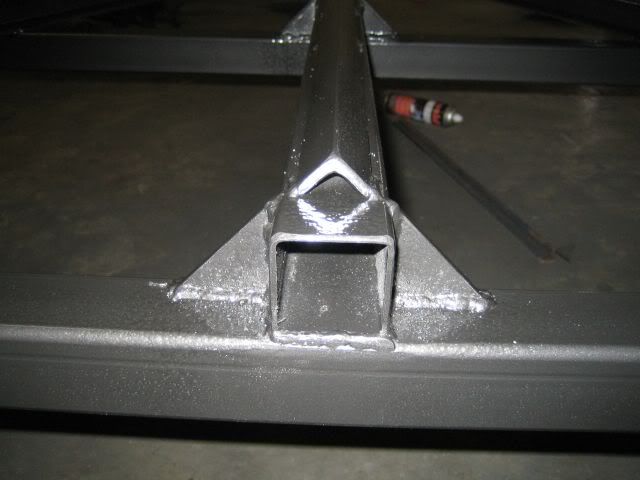

Tongue Bracing

After the many discussions about the strength of the Tongue, I decided to strengthen my tongue with 1x1x1/4 angle iron.

I also welded my flooring tabs as suggested by Mike!

(I'll nip this in the Bud, the trailers upside down!)

Tab

She's making progress, I plan to extend the current trailer by 18" this weekend to make more room in the galley and have a full 80" for the mattress.

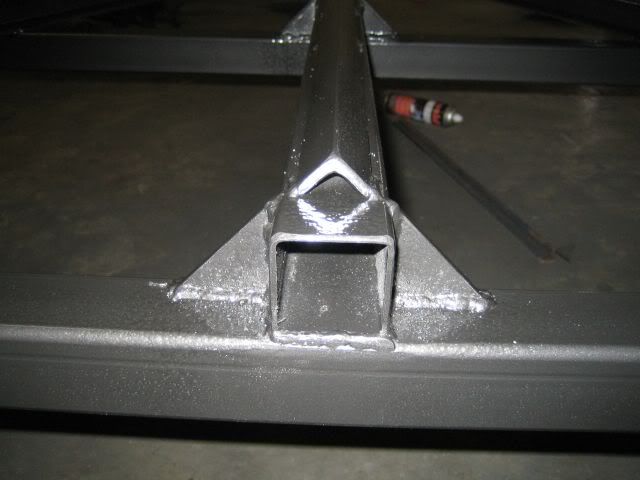

I also welded my flooring tabs as suggested by Mike!

(I'll nip this in the Bud, the trailers upside down!)

Tab

She's making progress, I plan to extend the current trailer by 18" this weekend to make more room in the galley and have a full 80" for the mattress.

Some of the time anyway

Some of the time anyway