Further research:

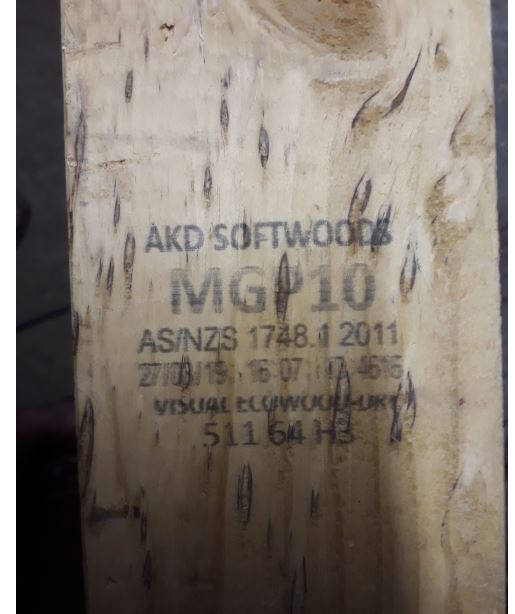

The timber was "tanalised" at plant #511 with azole preservative #64 to durability class H3 - outdoor above ground exposure.

- Timber Label

- label.JPG (43.1 KiB) Viewed 5135 times

I cut 2 inches off the end of a stick. The piece promptly split in two. Since I don't really want to open a $33 tube of sika flex 252 until I'm ready to go, I thought I'd start by gluing this two inch piece back together with the Sikabond Tech Grip polyurethane. This stuff seems the equivalent of Gorilla Glue polyurethane.

Apply to one surface sparingly, it said.

- Split.JPG (42.34 KiB) Viewed 5135 times

Then I clamped it lightly together, at which point it became obvious that Sikabond has a different interpretation of sparingly than I do, as glue squeezed out every surface. This bottle of glue is going to go a long way.

- Glued Joint Tech Grip.JPG (54.81 KiB) Viewed 5135 times

After an hour the glue has begun to froth a bit. This is "normal" for polyurethane I have read.

I intended to dampen the surface I didn't apply the glue to, but forgot in my haste.

I blame the 12 hour day at work. Still the fact that it is frothing suggessts that the glue is doing what it should.

I'll give it the recommnded 24 hours, sand the surface of the glued 2 inch piece and the same size surface area on the long stick it came from and see if I can glue the two pieces back together on the surfaces that always feel funny to me.

Then I'll give that 24 hours to dry. This is Monday night, 10pm. By about Wednesday night, 10pm, I expect to find out how well Sikabond Techgrip adheres to the outer surfaces of treated timber and also to the interior of treated timber.

Guess Amazon prime is no good there!

Guess Amazon prime is no good there!