Page 1 of 1

Quick, easy Butt Joint connectors

Posted:

Wed Feb 22, 2006 1:43 pmby cracker39

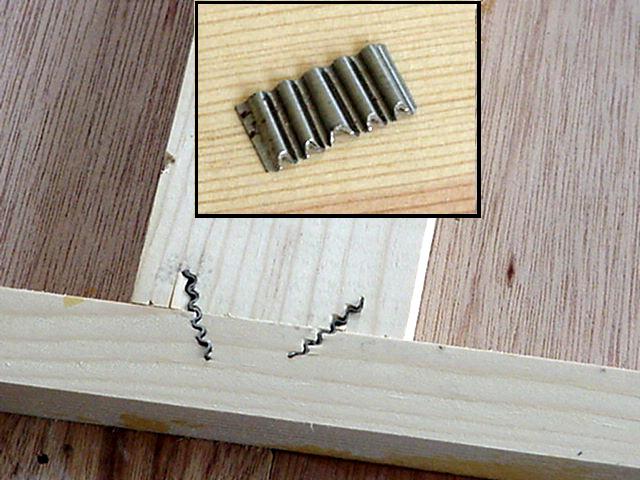

I don't remember what these connectors are called, but I think they were intended to mend wood framing on screen doors. I probably bought these over 20 years ago and they have just been sitting around in a jar waiting to be needed...and now, they're so happy that they are needed and finally being used!!!

I discovered them in my workshop stuff, and am using them to fasten framing pieces together as I construct my sides. They work great in pine or spruce (soft woods), but I doubt they would go into oak so easily. You just hammer one or two connectors into the wood to fasten them together. As you can see from the inset close up, they are wavy so they won't pull out easily. The're working fine for me.

Posted:

Wed Feb 22, 2006 3:32 pmby halfdome, Danny

They are corrugated fasteners. They use to be associated with the construction of orange crates but cardboard boxes are used now. Not the type of fastener I would recommend.

Dale be careful

Posted:

Wed Feb 22, 2006 3:42 pmby Guy

Dear Dale,

Corrugatoed fasteners were designed for crates and frames to be used on mitered edges and not as you are using them, especially since you are using them in opposigte directions and creating a narrow break which can pull out the whole trapezoid created by the angles. T way you could use themis to reverse the angles so that the trapezoid is larger on the bottom of your photo than on the top and extending out past your vertical frame.

Posted:

Wed Feb 22, 2006 3:46 pmby Ira

Boy, am I glad I don't have any of those…

Because I don't know WHAT the heck you guys (not just Guy) are talking about.

Posted:

Wed Feb 22, 2006 4:21 pmby Chris C

I was going to really let Dale "have it" until I realized he wasn't connecting anything of structure! All he is doing is connecting the framework for inside his walls..............and all of that will be glued to the plywood on both sides (I'm assuming), so no matter how he connects them, they should be alright. Now it would be an entirely different matter if he were using those to make a faceframe for the cabinets.

Posted:

Wed Feb 22, 2006 5:20 pmby cracker39

Thanks, Chris...you got the picture. No structural strength is required where I'm using these fasteners. They really hold the pieces together while the glue dries. I have glued and clamped or weighted all of the framing to the outside skin, and when I can get the side upright, I'll add some 3/4" screws from the outside through the skin into key framing pieces for insurance (i.e. sheet joints and a couple of horizontal pieces front to back). The windows and door will have screws through the skin into framing as well.

Posted:

Wed Feb 22, 2006 5:55 pmby EZ

Those things are a great idea! Most of the areas where they would be used are covered in plywood resulting in a huge corner gusset which will be really strong. Way faster and easier than a pocket hole for the proper application. I used staples to hold the 1 X's but they present their own problems (not countersunk, only holding 1 side, etc.). If I had thought of these, one at each joint would have worked perfectly. Maybe I can use some for the door framing and the bunk frame. Thanks for the tip!

Ed.

Posted:

Wed Feb 22, 2006 6:21 pmby angib

Dale,

An excellent application of a simple product. My compliments to you.

Even my engineering instructor would have approved (not something he did often, as I remember....) - he was the one who taught me that: 'An engineer is someone who can do for a quarter what any fool can do for a dollar'.

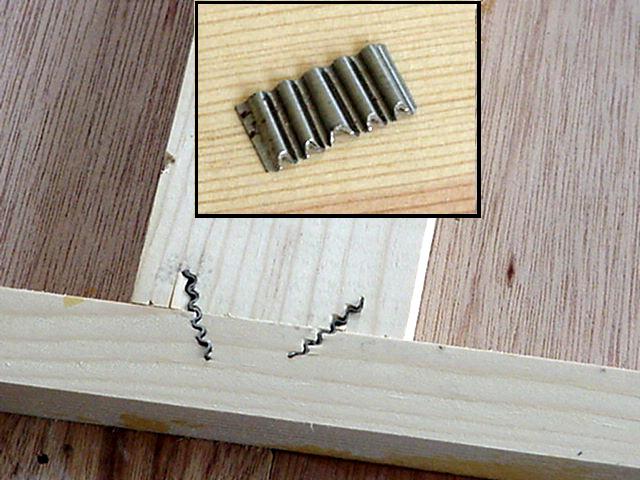

I think this guy is using those connectors too:

Andrew

PS Yes, that saying above has been converted to American units - could your fancy Mac have done that, Ira?

Posted:

Wed Feb 22, 2006 9:06 pmby cracker39

angib wrote:Even my engineering instructor would have approved (not something he did often, as I remember....) - he was the one who taught me that: 'An engineer is someone who can do for a quarter what any fool can do for a dollar'.

Andrew

Thanks, Andrew. I guess I just try to find easier and cheaper ways to doing things. I'm a tinkerer at heart. I sometimes go out of the way to do things differently. They're not always the best way, but they're my way.

Posted:

Wed Feb 22, 2006 9:37 pmby gman

Ira wrote:Boy, am I glad I don't have any of those…

Because I don't know WHAT the heck you guys (not just Guy) are talking about.

Ira, I'm just glad it wasn't a Brokeback Mtn kinda post.

Posted:

Wed Feb 22, 2006 9:38 pmby DrJerry

PS Yes, that saying above has been converted to American units - could your fancy Mac have done that, Ira?

...and just

WHAT may I ask, is wrong with a MAC?

Posted:

Thu Feb 23, 2006 12:13 amby Nitetimes

Posted:

Thu Feb 23, 2006 12:27 amby madjack

now that is how I always heard it

the other must be an engineers story...

madjack

Posted:

Thu Feb 23, 2006 12:29 amby Big Guy with a Little Guy

A butt joint connector?

I'm glad you posted a photo because I was picturing a shiny stainless steel clamp and a tube of super glue in the hands of a proctologist.

An image of Jack Elam just flashed into my mind...

the other must be an engineers story...

the other must be an engineers story...