new teardrop on home made trailer

Hello,

I'm building my first teardrop and have a question about building on the trailer. I picked it up on Craigslist from a welder who built it himself. It's a bit different because it's mostly 2"x2"x3/16" mild angle steel. Plus its big - 6' x 10'. And I'm also big - 6'4" 200+ lbs. I have a working design that includes a California king mattress but I need the exterior walls to be outside the trailer to fit the mattress width. (Should be enough room between the trailer and tires including the fender.)

but I need the exterior walls to be outside the trailer to fit the mattress width. (Should be enough room between the trailer and tires including the fender.)

I'm an engineer and pretty good wood worker / welder. But I do tend to over engineer projects. I keep paring this down (my first design had 2x4s!) but not sure I've pared down enough.

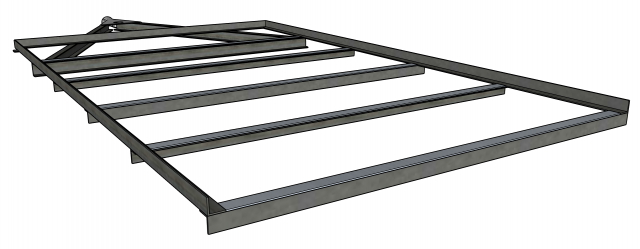

Here's a model of the trailer:

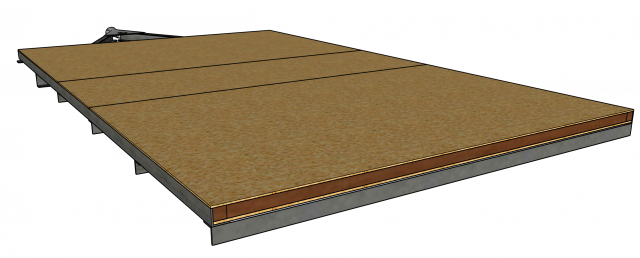

Trailer with deck:

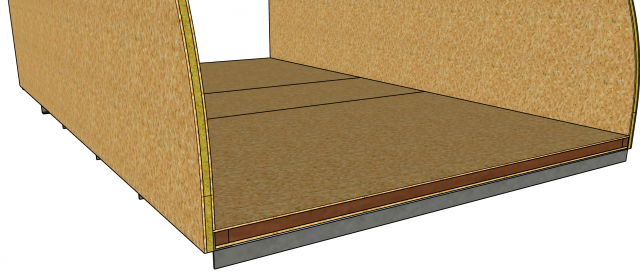

With walls:

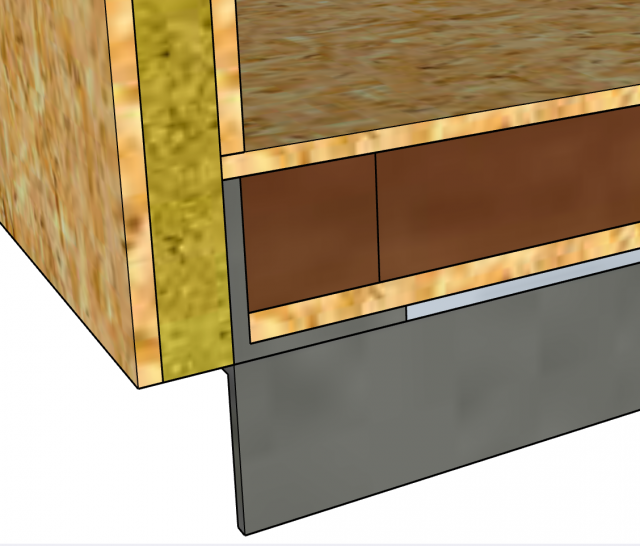

And closeup of the joints:

The bottom deck sheet is 5/16" (nominal) and the top sheet is 1/4" (nominal). This brings the bottom of the top sheet level with the trailer top and lets me add standard width rigid foam insulation to the floor but I'm reading most people say that's a waste. The walls are 1/4" plywood in and out with 3/4" plywood skeleton sandwiched in between. I'll probably bolt the deck to the frame with elevator bolts and then screw the walls to the floor from outside (through the trailer frame into the floor) with deck screws (I won't have access to the deck void to use bolts/nuts for the walls.)

I'd love to do aluminum outside but it's a little taller than 4' and a lot longer than 8' so I don't think that's an option. So I'm thinking painted fiber glass instead. Maybe match the color of my 2005 Suburban which would look sharp!

I bought a couple of the books I saw recommended and I'm reading lots of great posts (thanks for all the advice already here!) But I still would love some feedback.

Am I still over doing this? Any gotchas to watch out for with this type of trailer?

Thanks for this great forum!

I'm building my first teardrop and have a question about building on the trailer. I picked it up on Craigslist from a welder who built it himself. It's a bit different because it's mostly 2"x2"x3/16" mild angle steel. Plus its big - 6' x 10'. And I'm also big - 6'4" 200+ lbs. I have a working design that includes a California king mattress

but I need the exterior walls to be outside the trailer to fit the mattress width. (Should be enough room between the trailer and tires including the fender.)

but I need the exterior walls to be outside the trailer to fit the mattress width. (Should be enough room between the trailer and tires including the fender.)I'm an engineer and pretty good wood worker / welder. But I do tend to over engineer projects. I keep paring this down (my first design had 2x4s!) but not sure I've pared down enough.

Here's a model of the trailer:

Trailer with deck:

With walls:

And closeup of the joints:

The bottom deck sheet is 5/16" (nominal) and the top sheet is 1/4" (nominal). This brings the bottom of the top sheet level with the trailer top and lets me add standard width rigid foam insulation to the floor but I'm reading most people say that's a waste. The walls are 1/4" plywood in and out with 3/4" plywood skeleton sandwiched in between. I'll probably bolt the deck to the frame with elevator bolts and then screw the walls to the floor from outside (through the trailer frame into the floor) with deck screws (I won't have access to the deck void to use bolts/nuts for the walls.)

I'd love to do aluminum outside but it's a little taller than 4' and a lot longer than 8' so I don't think that's an option. So I'm thinking painted fiber glass instead. Maybe match the color of my 2005 Suburban which would look sharp!

I bought a couple of the books I saw recommended and I'm reading lots of great posts (thanks for all the advice already here!) But I still would love some feedback.

Am I still over doing this? Any gotchas to watch out for with this type of trailer?

Thanks for this great forum!