Page 11 of 17

Posted:

Tue Feb 28, 2006 9:14 amby Miriam C.

Mike,

I'm luvin it. Wonder if HF would sell only the pieces needed to make that.

Just the Axle, bracket, and maybe the tongue? Oh yeah and the tires. (

Was there anything else to that trailer to start with

)

Think some strong male voice should call.

Miriam

Posted:

Tue Feb 28, 2006 9:20 amby toypusher

Tractor Supply sells all the parts you need for that setup. (not exactly, but very close)

Posted:

Tue Feb 28, 2006 9:25 amby toypusher

Have any of you seen this??

http://www.tapeease.com/vacuum_bags.htm Might be a good way to build the floor and walls!!!

Posted:

Tue Feb 28, 2006 9:42 amby mikeschn

Food for thought Kerry!

I like the large table, but that baby is $8000. Ouch...

Mike...

Posted:

Tue Feb 28, 2006 9:45 amby toypusher

Mike,

I did a google search for places around here that do that and there are 3 or 4 close by. I have not talked to any of them yet, but will call a see what they would charge to do say a 4x8 of styrofoam and plywood sandwich. Might be a good way to make larger pieces, like 4x9 or 4x10 if the price is not too high. Get the sandwich made and then have it waterject cut!!!

Posted:

Tue Feb 28, 2006 12:18 pmby angib

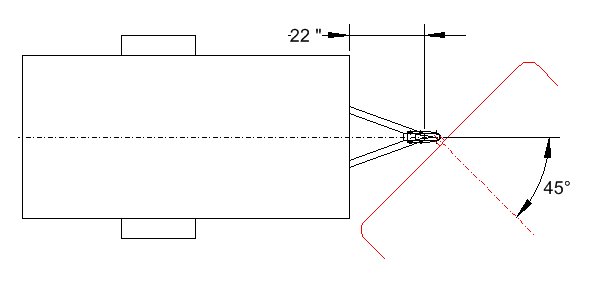

mikeschn wrote:I believe Andrew worked it out and said the car can angle 45* before touching the trailer. Andrew, did you have a picture of that?

Andrew

Posted:

Tue Feb 28, 2006 12:29 pmby Mitheral

If I go with a variation of the ultra light design I've given thought to vacuum bagging the floor, walls and hatch. I've even got the pump sitting under my workbench though it might be better on this project to just use a shop vac.

Posted:

Tue Feb 28, 2006 12:49 pmby mikeschn

Miriam C. wrote::twisted:

Mike,

I'm luvin it. Wonder if HF would sell only the pieces needed to make that.

I doubt it...

You could always use the extra steel to make some gorilla shelves to use in your basement!

Mike...

Posted:

Tue Feb 28, 2006 12:49 pmby bg

That's the whole structure, tacked, waiting for finish welding. Weight of what you see is 102 lbs.

It's *very* rigid, And I'm very happy with how it's turning out.

Time log is 11 hours now.

Posted:

Tue Feb 28, 2006 12:51 pmby mikeschn

BG,

Are you not going to have a hatch?

Mike...

Posted:

Tue Feb 28, 2006 12:55 pmby bg

Mike,

It's not that I'm scared of doing a hatch, It's just that don't see the need for my use. It would be *very* easy to do, but the added expense is an issue.

Posted:

Tue Feb 28, 2006 2:02 pmby bg

Slid it onto my trailer, and tucked it in for the day.

Posted:

Tue Feb 28, 2006 3:17 pmby vairman

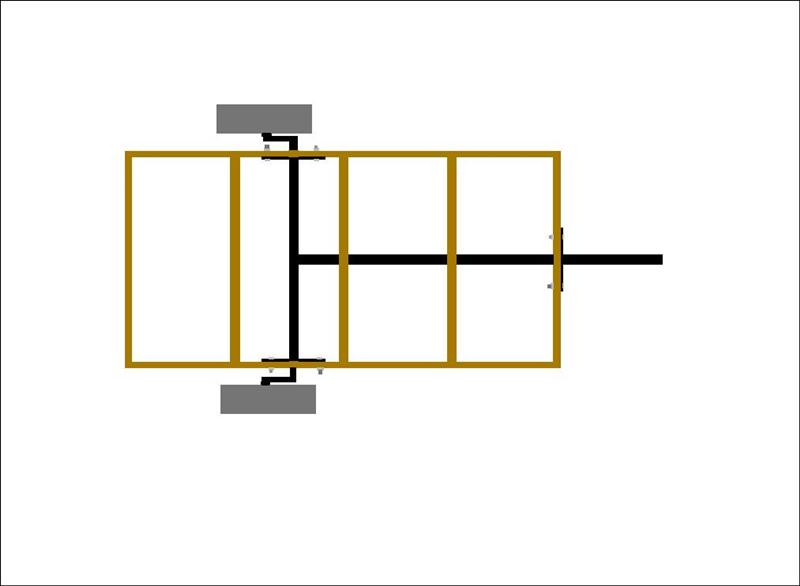

How bout this for a light weight frame... at the axel and tongue there is angle iron the the frame is bolted too...

Greg

Posted:

Tue Feb 28, 2006 3:31 pmby mikeschn

Seems to me that would work well if we used those little haft stub torsion axles... You know, the kind that are on all the Urpeen Caravans, and seldom seen over here...

Mike...

Posted:

Tue Feb 28, 2006 4:53 pmby bg

Even though I packed up early today, I keep wandering into the garage wondering if there's anything else I feel comfortable doing today. The structure is so strong I keep wondering if I really need the added strength from the A-Frame. Regardless, it'll be cheap insurance to have a little extra support under there.

I'll be staying hatchless, but it wouldn't be terribly compilcated to add one at a later date if I choose to do that. My *plan* is to be able to finish the interior with cloth panels, filling the voids in the framing. I should be done with the welding tommorrow. Then it's just a simple matter of attaching the skins, and sealing the edges.

I don't want fancy, I want functional.

Was there anything else to that trailer to start with

Was there anything else to that trailer to start with  )

)