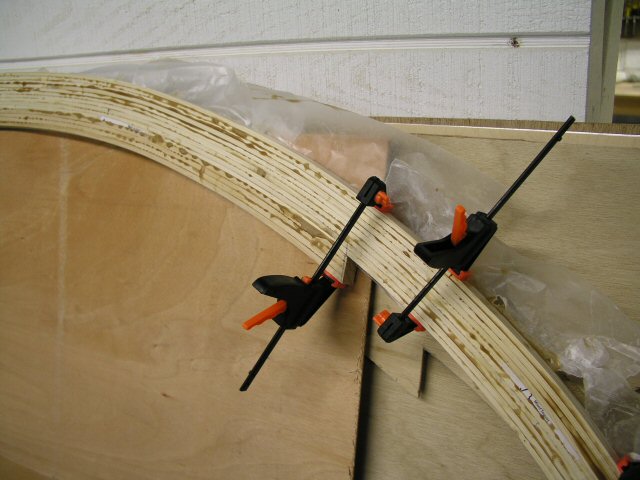

Kerry just asked for more pictures of my Ultralight construction... I've been gluing up laminations for 3 days now, and all I have to show for it is a couple swoosh drops...

Here's the pictures of one side, and the other side is similar...

In this picture you can see the part of the framing that is going to be above the door. The ultralight only has 1 door btw... The other side gets a window.

In this picture you can see where the hatch begins... in other words, what you are looking at is the notch for the hatch insulation...

And in this picture you can see where the hatch ends...

Tomorrow I take the whole mess outside and run it thru the thickness planer!

Mike...

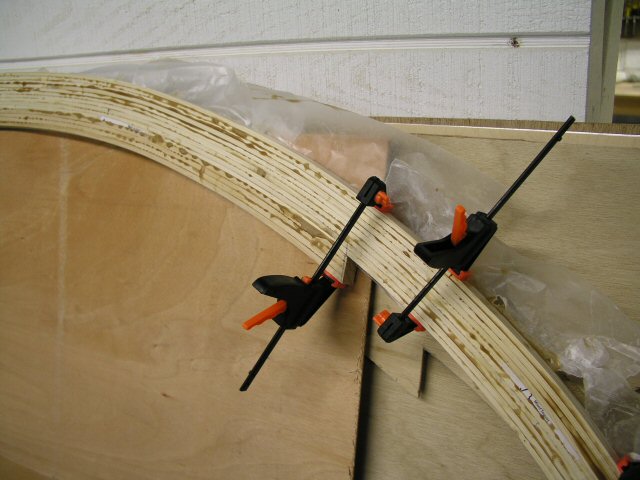

Here's the pictures of one side, and the other side is similar...

In this picture you can see the part of the framing that is going to be above the door. The ultralight only has 1 door btw... The other side gets a window.

In this picture you can see where the hatch begins... in other words, what you are looking at is the notch for the hatch insulation...

And in this picture you can see where the hatch ends...

Tomorrow I take the whole mess outside and run it thru the thickness planer!

Mike...