I've been hanging around the forum for about a year trying to soak up the wisdom and expertise of the members here. I've been dreaming of the day when I can begin building a teardrop camping trailer for myself. Sadly, for a multitude of reasons, it appears that I will have to wait a while longer.

Here in Minnesota, classic cars and street rods are very popular. I have been fortunate enough to make a successful business of building, repairing and restoring classic cars and street rods.

Recently, one of my customers, knowing of my desire to build a teardrop trailer, asked me if I could build a teardrop cargo trailer to haul spare tires and other miscellaneous road tripping essentials behind a '32 Ford Victoria street rod I am building for him. Of course I jumped at the chance.

He has made his expectations very clear:

1. It needs to have a traditional teardrop camping trailer profile.

2. The trailer has to use the same wheels and tires as the front axle of the car (215-60R17 with 17 x 6" wire spoke wheels)

3. It needs to be able to carry at least one rear tire (28" dia. by 10" wide), a floor jack, lug wrench, and the two hood side panels (34" w x 23" h).

4. The fenders have to match the car.

5. There can be absolutely no wood structure in the trailer.

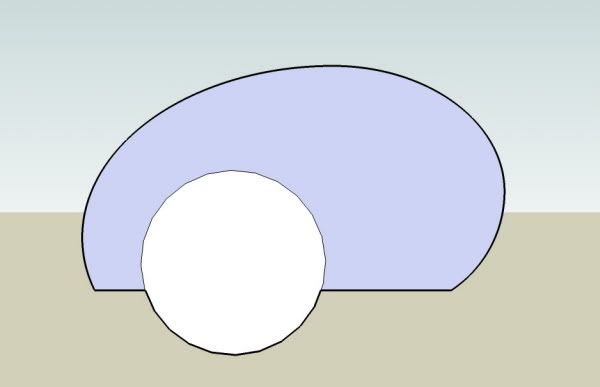

So with that in mind, I have decided that the profile will be similar to the Grumman 2. The profile will be scaled down and the flat section in the roof will be eliminated. That will make the trailer body 64" long, 34" high, and about 36" wide which should be just large enough to haul the necessary cargo. 8" of ground clearance will make the overall height about 42".

I am a newbie to Sketchup, but here is the basic profile I'm shooting for:

I plan to make the body completely from aluminum, with square tubing forming the profile and aluminum skin welded or bonded to it. The frame will be steel and only the tongue will be exposed. The trailer body will also have an aluminum diamond plate belly skin. The hatch will be hinged much further forward than a traditional teardrop galley hatch to provide easy access to the cargo. The fenders will be original steel '32 Ford pick-up fenders which will be widened as necessary. The hood side panels will be stored cross-wise in the nose of the trailer ahead of the spare wheel(s). I'm toying with the idea of a door in the side of the trailer and a slide out rack for the hood panels. Upon completion, the trailer and wheels will be painted to match the tow vehicle.

There are a few design hurdles I need help with.

First and foremost, the axles. I need to come up with a suspension setup that has stout enough spindles and bearings to handle the huge heavy wheels, yet still have a low enough capacity to allow the trailer to tow smoothly. I don't expect the weight of the trailer to be more than about 300# loaded, but the wheels are 27" tall and weigh about 40# each. I am not a fan of slipper springs, because they tend to be noisy. I would prefer torsion stub axles, but I would have to have them custom built - if that is even possible. There must be some options that I am overlooking. Any suggestions on this subject would be greatly appreciated. Cost is not a factor

The other quandary that weighs heavily on my mind is how I will bend the aluminum tubing into the elliptical profile of the body. My plan for now is to build a heavy wooden form and bend the tubing around it using muscle, clamps and heat as necessary. I am very open to suggestions on this subject as well.

With the wealth of knowledge and experience you, the members of this forum have, I am sure I will find the answers I need.

Thanks.

Joe G.

P.S. Just in case anyone is wondering what a '32 Ford Victoria looks like, here's what it looked like when I received it. The finished product will sit much lower, have modern wheels and tires, and a 354 Chrysler hemi with 3 deuces, 6 speed manual trans, custom tubular chassis, 4 wheel independent suspension, disc brakes, electric power steering, air, cruise, etc, etc. etc.... and, of course, a trailer hitch.