Hazardous Last Update?

Happy New Year to all!

I started cutting out my patterns today!!

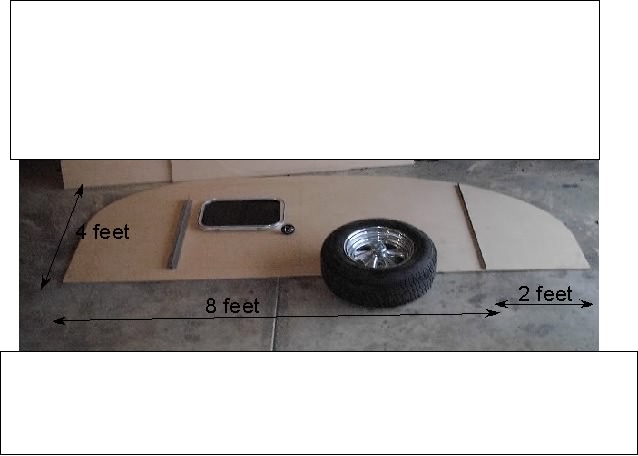

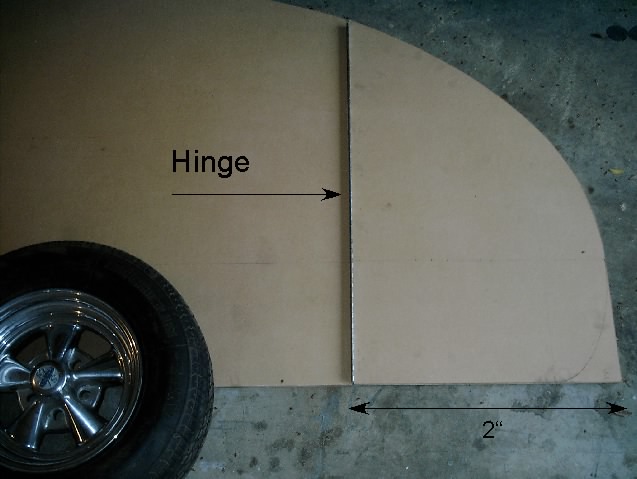

For my Teardrop I am trying something a little different. If you look at the photo you can see a hinge two feet from the back of the trailer. The hinge will let the sides of the trailer open outward so that the counter top can be folded out to give me a ten-foot wide counter. I have several questions that this enlightened group may be able to help with.

One thing that is not shown is a box on the front for AC and a generator.

1st On the hinge, I have Grant’s aluminum piano hinge. How much weight can it hold.

I would like to swing the back 1-foot of the trailer with a drawer in it out to the side?

Will this overload the hinge?

2nd What would be the best height for the counter top?

3rd Any suggestions on cabinet and axel placement?

Thanks from Dan

I started cutting out my patterns today!!

For my Teardrop I am trying something a little different. If you look at the photo you can see a hinge two feet from the back of the trailer. The hinge will let the sides of the trailer open outward so that the counter top can be folded out to give me a ten-foot wide counter. I have several questions that this enlightened group may be able to help with.

One thing that is not shown is a box on the front for AC and a generator.

1st On the hinge, I have Grant’s aluminum piano hinge. How much weight can it hold.

I would like to swing the back 1-foot of the trailer with a drawer in it out to the side?

Will this overload the hinge?

2nd What would be the best height for the counter top?

3rd Any suggestions on cabinet and axel placement?

Thanks from Dan

.

.

, profile of my design with fender. It was easier to see this way than adding it to the photo.

, profile of my design with fender. It was easier to see this way than adding it to the photo.