Simple_Abound wrote:I've camped in 20 degree to 90 degree weather with my homemade pop up square drop. If you don't have proper ventilation in cold weather you'll have condensation issues. ...

I, too, have camped in both cold and hot weather in my homemade squareback trailer, but it was a range from 35F-105F temperatures. being in N.Texas/S.Oklahoma in the spring, early summer. The use and amount of insulation used really depends on when and where you'll be camping. I knew I'd be camping 99% of the time in warm-hot weather (even our winters are warm compared to other climes), so I really didn't consider insulating the trailer, until after I experienced cold sidewalls inside, when I'd roll over in my sleep at night (the inside width is only 46.5"). My solution was to put indoor/outddor carpeting squares on the sidewalls in question...problem solved.

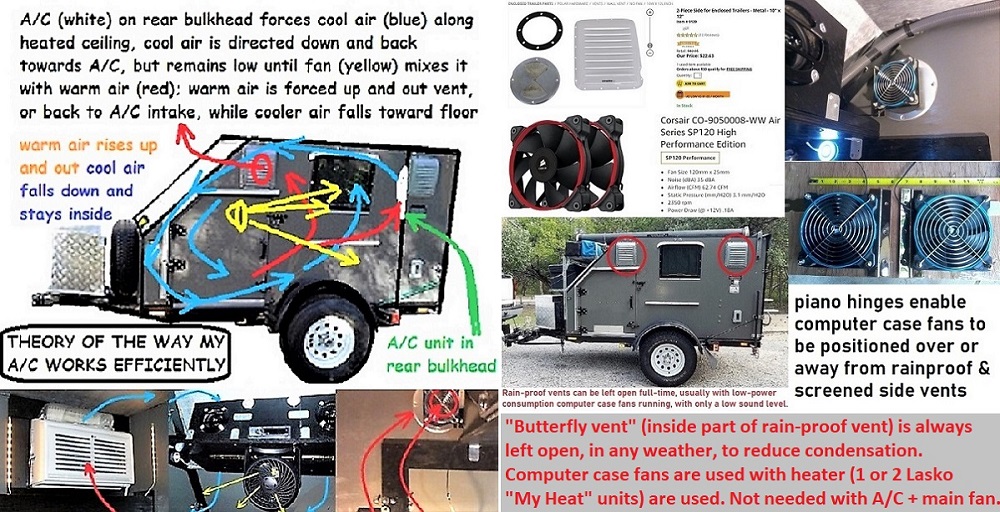

There's been no condensation inside my cabin (except for the night when I had 1-2" of standing water inside, due to leaving a door cracked open during T-storms), because I have as much airflow as I'd ever need to push moisture out thru two side vents, two windows, or the humidity expelled thru the A/C. The waterproof side vents are always cracked open, 24-7-365, and usually have a computer case fan pushing or pulling air thru them. If more airflow is needed, there's an 11" fan that I can use, and the A/C fan can be added to that. Never any inside condensation, but on a warm/hot day or night, there's plenty of condensation on the exterior, when I run the A/C.

- crude representation of airflow inside the cabin; there's always air moving inside and zero condensation

- airflow and condensation reduction in my 4x8.jpg (304.36 KiB) Viewed 775 times

Pmullen503 wrote:...I've done some sub zero camping in my unheated foamy (2" XPS). Based on what sleeping bag/liner I need to be comfortable, I'd say the effect is like adding 15 degrees F compared to tent camping. The air is definitely not 15 degrees warmer, I think it's due primarily to less radiant heat loss from me.

My trailer doesn't have the inherent insulating properties that a foamy constructed from 2" XPS would have; 3/4" plywood walls (ceiling & floor, also) give little insulation, though my floor covering ( a rubber+carpet industrial mat) does provide a little. I have used between 4"-8" of foam mattresses, comforters and blankets in the past, to keep warm, but I've simplified my method in later years. I now use a 4" (folding) mattress, plus either a Coleman 20 degree or 50 degree sleeping bag, and one or two Lasko "My Heat" 200 watt "personal" heaters (located on an overhead shelf, since they don't have tip-over protection) I've used them for many years, when I've been stranded at work during ice storms and slept in the back of a truck with an aluminum shell in back, or inside my HHR Panel ...bought with such a use in mind...at temperatures down to 4F, using the 20 degree bag, plus blankets. I was a little cold in the aluminum shell, a little warmer in the HHR, but it wasn't too cold to sleep. Perhaps I should've taken my trailer to work? (a 120-mile round-trip) I'm sure it would've been more comfortable.

- I've used two Lasko's for many years, even to heat under-sink areas (in my house, none in trailer) during sub-freezing weather

- Lasko.JPG (113.29 KiB) Viewed 775 times