Step 21: Build the doors – ¾” birch plywood

Step 21: Build the doors – ¾” birch plywood

You cut out the doors already in step 4. Now it’s time to finish them.

You want to end up with a 1/8” gap all around the door, after the t molding has been installed. So your finished door size needs to be 3/8” less than the opening size, both vertically and horizontally. The easiest way to get your door to size is to rip off the appropriate amount off of the straight edges using your table saw. Hang the door with your stainless steel hinge and test for fit. The hinge should extend beyond the top and bottom of the door by ½”.

With your doors properly sized, cut out the opening for the window.

Stain and polyurethane the inside surface of the door to match the cabin. Paint the outside and the edges with CPES and Uniflex.

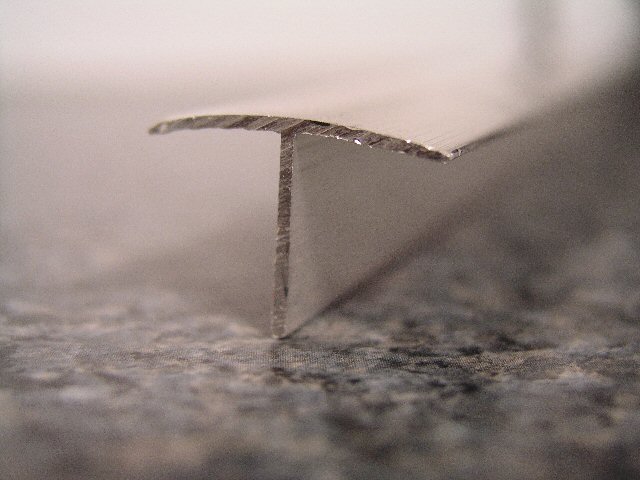

Bend some deadsoft t-molding around the edge and fasten it with stainless steel flat head screws. Also fasten a straight length along the bottom edge. Attach a stainless steel hinge along the long vertical edge. Install your door handle. I notched out the t-molding with a grinding wheel for the door handle. Finally, install a window in the opening, with a good bead of silicone caulk for water proofing.

Your door should now look like this.

Hang the door on the body with stainless steel flat head screws. Pick a length that won’t break through the inside of the wall.

You cut out the doors already in step 4. Now it’s time to finish them.

You want to end up with a 1/8” gap all around the door, after the t molding has been installed. So your finished door size needs to be 3/8” less than the opening size, both vertically and horizontally. The easiest way to get your door to size is to rip off the appropriate amount off of the straight edges using your table saw. Hang the door with your stainless steel hinge and test for fit. The hinge should extend beyond the top and bottom of the door by ½”.

With your doors properly sized, cut out the opening for the window.

Stain and polyurethane the inside surface of the door to match the cabin. Paint the outside and the edges with CPES and Uniflex.

Bend some deadsoft t-molding around the edge and fasten it with stainless steel flat head screws. Also fasten a straight length along the bottom edge. Attach a stainless steel hinge along the long vertical edge. Install your door handle. I notched out the t-molding with a grinding wheel for the door handle. Finally, install a window in the opening, with a good bead of silicone caulk for water proofing.

Your door should now look like this.

Hang the door on the body with stainless steel flat head screws. Pick a length that won’t break through the inside of the wall.

but hey why not it fits the question.

but hey why not it fits the question.

Didn't see that the first time looks like I have some reading to do.

Didn't see that the first time looks like I have some reading to do.