has anyone went with a aluminum trailer frame?

31 posts

• Page 2 of 3 • 1, 2, 3

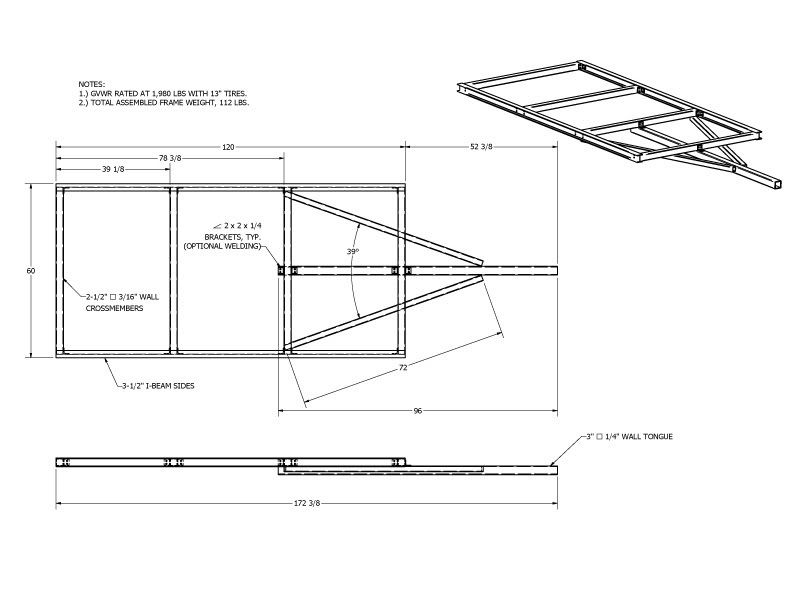

i can give you the basic cross section dimensions of the i-beam i will use, but i cannot post a drawing. i should note, that the i-beams we use are not standard i-beam profiles. they are profiles designed specifically for trailers. more specifically, boat trailers. now, if you had one of our trailers, you'd have the cross section. i just cannot post it or give out drawings. kind of crazy huh? the design of the side rails, cross members and tongue play a good part in the integrity of the trailer, but one key component is the axle. without the correct axle size, the frame is compromised. that goes for steel frames as well. you can take it even farther down and look at tires. they are load rated specifically for trailers. they don't really have as much of a factor in light tears though. i will post up my intended frame design as soon as i'm happy with it and i'll post up what materials i'm using and where. hell, i'll post up my fully dimensioned frame drawing in case someone wants to use it. i will have axle size and load ratings with my drawing, along with spring ratings and torsion arm ratings. i'm going with torsions, but i'll design for either. i'm designing a pretty broad safety factor, so my frame will seem overkill, to me anyway. but it will be light, that's for sure. i'm actually, thinking it may be too light on the highway.....guess i'll have to test that after it's built.

- shawnkfl

- Teardrop Advisor

- Posts: 51

- Joined: Sat Mar 15, 2008 6:53 pm

Brian-bp: good posts, thats what I came here to say. The article appears to be more of an observation than facts. It sounds like the Horse trailer industry switched materials without re-engineering the designs for the new material propertys, and thus had failures.

*****************************************

Mike

Mike

-

G-force - Teardrop Master

- Posts: 204

- Images: 22

- Joined: Wed Jan 16, 2008 2:42 am

- Location: So. California