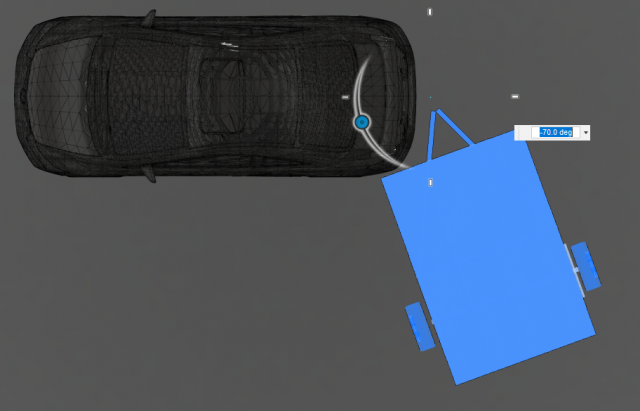

Here's what it looks like rotated by 70 degrees.

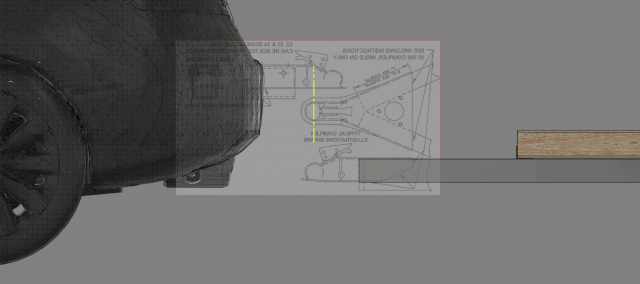

The yellow line is where the ball of the hitch will most likely be. Even if the ball is a little closer to the car I should be fine.

I won't be switching vehicles any time soon, but there probably wouldn't be room for the hatch to open. There is enough room for the car's trunk to open though.

What is "the mix"? Epoxy would be nice but it's expensive.

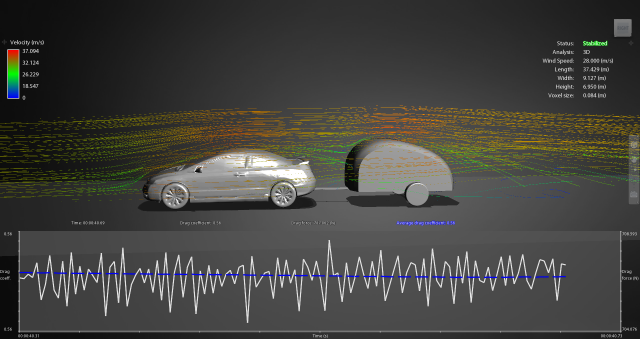

I haven't done any simulations with a Tacoma model, but here's a simulation of a normal teardrop and a Civic. There's 34" of separation between the trailer and car.

There isn't a huge amount of swirling air, but there is a pretty large increase in drag force. Just the car is 265 N whereas with the teardrop the drag is 707 N (about 2.65 times the drag). I'd imagine the increase is smaller with the truck as the roof is much closer to the roof of the teardrop.

Thanks for the tip on the stressed skin manuals. I'll take a close look at those later but they look to be helpful.

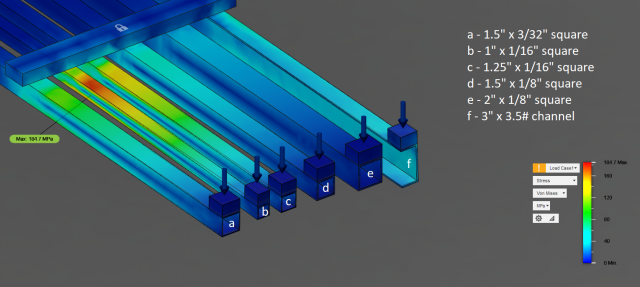

I've run some stress tests on the channel, yep it's a bit too much. I can swap it out for a 1.5 x 1/16" square tube. Here's the simulation if you guys are interested. 6 different types of beams, simulated with ASTM A36 steel and a 600 N (about 135 lbs) load applied. I'm guessing the tongue weight will be about 115 lbs max so a safety factor of a little over 2 should be fine.

Weights of the beams:

a - 6.34 lbs.

b - 5.85 lbs.

c - 5.24 lbs.

d - 11.69 lbs.

e - 15.94 lbs.

f - 12.13 lbs.