by Trackstriper » Thu Apr 17, 2008 11:30 pm

by Trackstriper » Thu Apr 17, 2008 11:30 pm

Justin,

Got questions for you. You're planning on doing a Cub correct? Are you going to use the general plan for the "New Cub" that Andrew has in the design library? Can you open the zipped .dxf file with suitable CAD software to get accurate dimensions?

The following assumes that your are using his design or something very similar:

The good news: An "A" frame coupler will add about five inches of effective tongue length to your tongue tubes - from the end of your tubes to the center of the hitch ball. Thus the hitch ball would be about 43" from the front of your frame.

The (maybe) bad news: There is a sizable front overhang of the body past the perimeter frame with the New Cub. I'm showing about 19.5" past the frame per Andrew's drawing. That will eat up some of your 43" of tongue length leaving you with about 23.5" of tongue extending beyond the extremity of the body. That might be very tight, but it could depend upon what you are towing it with and how far back your tow vehicle's ball mount extends.

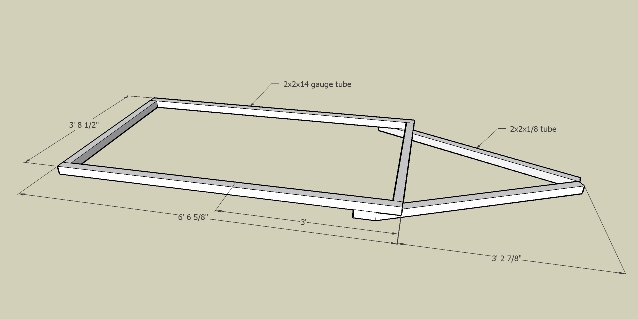

I think that you could get creative and move the front cross-tube of Andrew's design forward 8", maybe 9" and still keep it within the bodywork...that might give you more tongue. His design is for a single tube tongue, and it's fairly long at 55.5" ball to frame, with 36" from ball to overhead bodywork. By lengthening the frame sides up to 9" you could get about 32-33" from ball to bodywork, approaching his design dimensions. Check with Andrew to see if this creates any problems I'm not picking up.

Now, your frame side pieces would be longer and you would need to reallocate the tubing requirements. Probably two 20' sticks of something square as you couldn't get the side pieces and cross-tubes out of a 20' stick. Your steel dealer might have 24' stock and you'd be OK if you wanted to use different gages for the perimeter frame and tongue.

My instinct is to pick one gage and go with it for tongue and perimeter frame. Think about it this way, if you hitched up the bare frame with axle and wheels to your car and then tried to fail the tongue, what would happen? A good way to do this would be to hang a bunch of sandbags over the front cross tube, then have yourself and a heavy buddy bounce up and down on the frame at the juncture of the tongue and side rail. Something will eventually give. If not, add more sand bags, repeat! If you use 11 gage tube for your tongue and 14 gage tubes for the side rail, I'd put money on the side rails failing just aft of the welds attaching the tongue, assuming that all the welds are done well so that they are not the failure point. I think this juncture area is the highest stress area that you are dealing with with respect to tongue failure. If you used a 14 gage tongue and 11 gage side rail, then it should fail on the tongue side of the juncture. Why not use the same gage, be it 11 or 14 throughout? I'm thinking, use tongue and side rail material of similar strength in this case. I know that the body can contribute some strength to the side rails, but with this design there is very little overlap of tongue and side rails so I think this effect would be minimal.

Do your math with Andrew's charts. An "A" frame tongue with 2" square 11 gage is probably strong enough, it's about 45% stronger than the 2" square 11 gage single tube that failed on Rocky's trailer . He apparently loaded his up pretty well for the move to Georgia and had some bumpy/lumpy roads, but he evidently hadn't had any problems with it before this trip, it had served him well. And it sounds like you want to go fairly light with the build. If you're not comfy with that, go with 11 gage throughout...it won't weigh but a few pounds more, who cares?

Buy the proper hanger brackets for the axle so you can replace it if necessary, and you won't have to weaken your frame with any through bolts of significant diameter.

If you guys see something wrong with this logic, let me know 'cause I'm in the learning process too, I won't be offended.

J.B.