I don't see that Andrew has sent you a link to his Tongue Strength design information. It's full of good information and well worth printing out to use as a design reference. It's available up above in the Design Library or by clicking this:

Tongue Strength

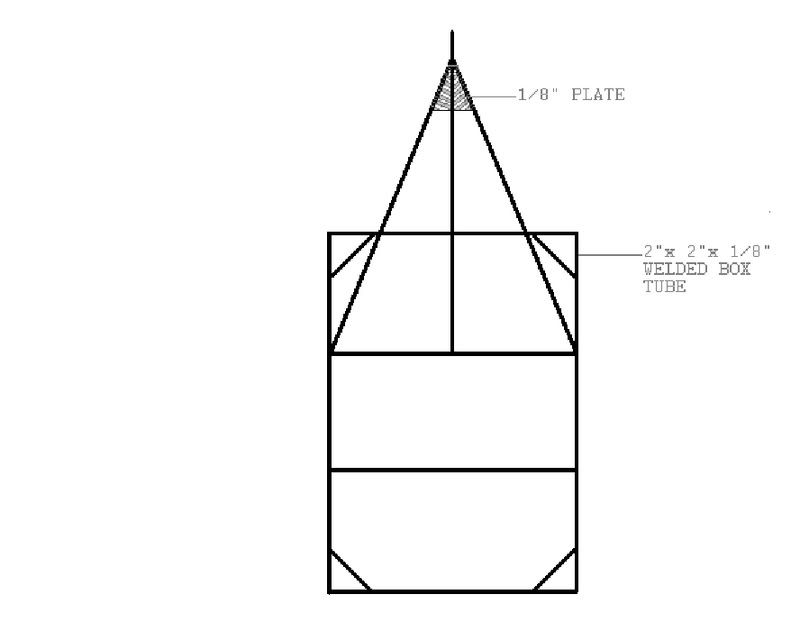

I'm designing my frame too. Trying to keep it as light as reasonably possible with a strong enough tongue. I'm going back and forth between using an A Frame or a Composite Frame - like your design above. I'm designing a 5'x 10' teardrop and am hard pressed to keep it's weight low as my tow vehicle has only a 1500 lb. capacity. In ballpark figures the frame, axle, tires, and jacks will weigh 350-400 lbs. The wood floor, sides, and roof/hatch will weigh another 400 lbs. or so. Aluminum skins and trim, cabinets, windows, the battery and electrical system will add some more hundreds of lbs. An empty 5'x10' teardrop may easily weigh around 1100-1200 lbs. which does not leave much capacity, in my case, for bedding, a stove, an ice chest, food, ice, drinks, water, chairs, an Easy Up, and other personal camping stuff. Not trying to thread jack, but to interject that if you build a 5'x 10' you'd need to design for a tongue with a strength well over 1500 lbs. according to the Aussie tongue strength rules.