by eamarquardt » Sun Dec 16, 2007 10:37 pm

by eamarquardt » Sun Dec 16, 2007 10:37 pm

Hi,

The vertical strength does not come from the sides. It comes from the top and bottom surfaces being in tension and compression. That's why "I" beams have a top, bottom, and only one vertical element. What I have done in the past is to cut a square tube into quarters removing enough in the middle of each flat surface to fit inside the tube you are trying to splice. Then you weld the extension on using the 4 pieces as internal backing plates. Then you can grind off the excess weld and you have a nearly invisible splice (depending on how much effort you put into it). I sometimes drill 4 holes in the two pieces being spliced together and then plug weld the backing plates a ways away from the acutal splice point. Overkill I'm sure, but it doesn't cost any more or take much time.

I know this is a bit late, as it seems you've finished but maybe someone else can use this technique. Your finished product looks nice.

Cheers,

Gus

The opinions in this post are my own. My comments are directed to those that might like an alternative approach to those already espoused.There is the right way,the wrong way,the USMC way, your way, my way, and the highway.

"I'm impatient with stupidity. My people have learned to live without it." Klaatu-"The Day the Earth Stood Still"

"You can't handle the truth!"-Jack Nicholson "A Few Good Men"

"Some people spend an entire lifetime wondering if they made a difference in the world. The Marines don't have that problem"-Ronald Reagan

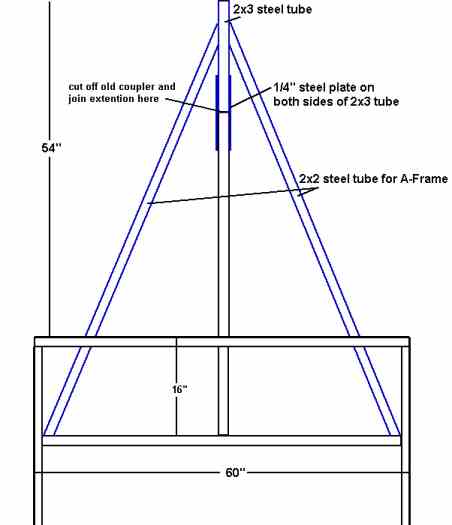

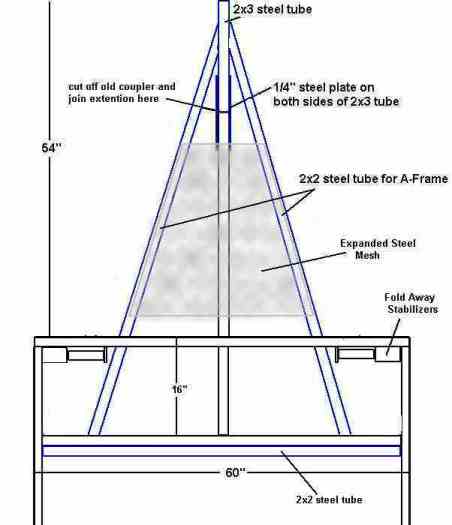

is a little short and I need some help with extending it. What I have is a single tongue 2"x3" 11 Guage that extends 36" from the frame.

is a little short and I need some help with extending it. What I have is a single tongue 2"x3" 11 Guage that extends 36" from the frame.