Cliffmeister2000 wrote:That looks really nice but I don't understand how it will save much weight. It will be interesting to see how you waterproof it.

Regarding the weight issue: The sliding hatch will be a piece of 5 mm flexible triplex with a 0.8 mm aluminium skin. A hinged hatch of the same size has the same piece of 5 mm triplex/aluminium plus a frame with two curved side timbers and at least 4 cross-members of 44 x 27 mm (or similar size). The gas struts to support it would also add weight. My target to to build a sub-250 kg tear, so every kilogram saved helps.

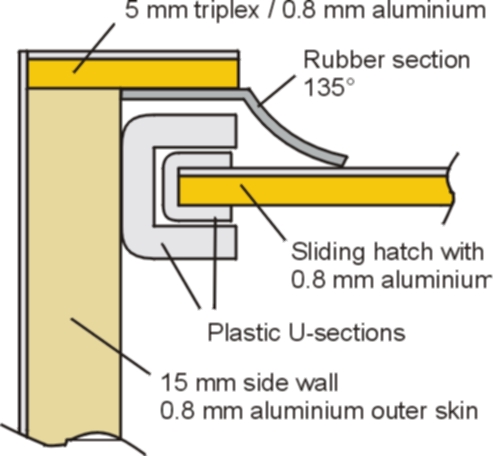

The waterproofing is an issue. Here's my provisional idea. The curvature of the hatch (made from 5 mm flexible triplex with an aluminium skin) gives it some rigidity. Edges are finished with a plastic u-section glued in place. A larger plastic u-section (loose fit over the u-section on the hatch) formed to an arc is secured to the inside of the side panels left and right. These channels extend into the cavity in the roof. A rubber section (normally used in automotive applications) can form a loose seal as shown in the diagram below. A similar construction would be used at the top.

I realize this may not be totally water tight, but since I have no plans for fitted kitchen elements, I can seal the galley area and use waterproof surfaces. Some water entering here will not be critical.