Thanks Hank & Earnest!

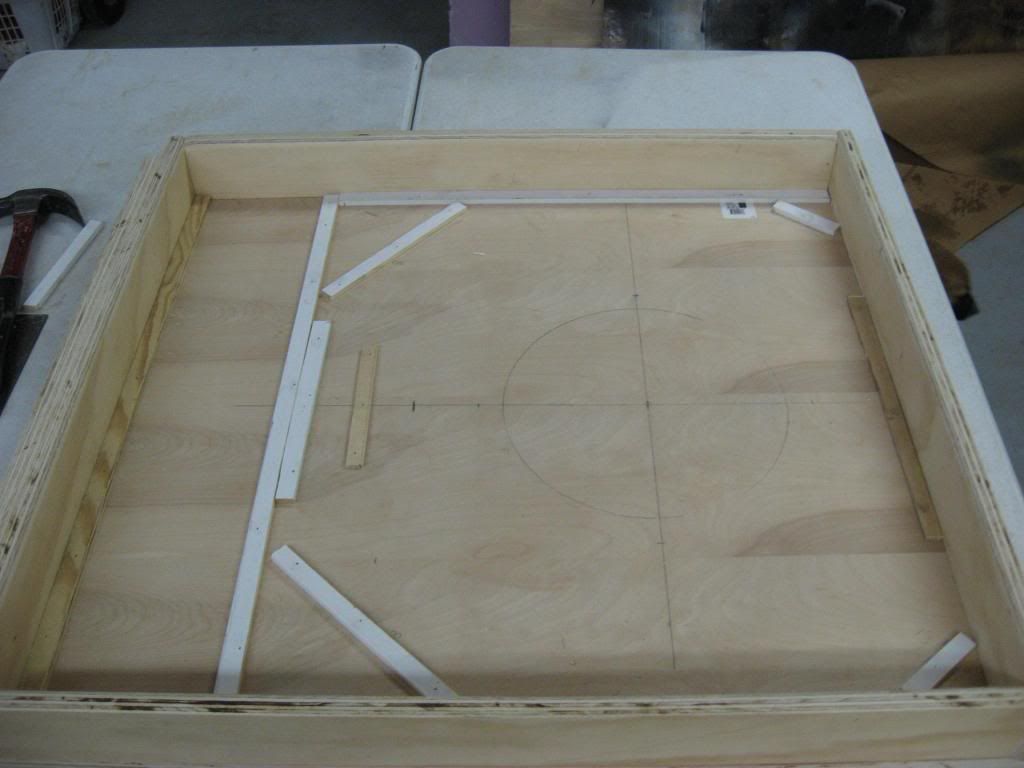

Today, I reworked the pan and fixed the slope problem. First I ground off all the bondo and roughed up the wood. You can see the cuts I made in the wood when I tried the first time to fix it.

Then I pulled the pan into the correct position with a 7" round piece of wood on the other side, screwed into the cross beam. I then laid two fiberglass mats down. When it hardened the pan stayed in position and now has the correct 1/4" slope.

The drain hardware is a generic fitting which I could only find at jazzsales.com pn#721342. It is plastic and almost not long enough. I am going to silicon rtv it in place. The drain connects to a HepVo trap, and abs connector.

I didn't want a conventional 4" drain shower drain assembly because it would put the exit pipe too low.

So here's how I SHOULD have built it:

- instead of a 3/4" base piece, use several 1" cross beams and screws like above to hold the panel in position.

- cut panel partway through as above to make it more flexible if necessary

- lay one mat on the top surface.

- lay two mats on bottom surface

- remove cross beams, screws - surface should not spring back

- cut 3" drain hole all the way through fiberglass and wood

- lay more mats on top surface, fill holes, and build up flange underneath

- gel coat (should have used the waxed type which cures hard where exposed to air)

- fill remaining space underneath with thinset mortar for support

at a nice steady 160 watts

at a nice steady 160 watts

Lots of work for what fits your needs is worth every minute. I enjoy the effort that folks here put into their projects to make it theirs.

Lots of work for what fits your needs is worth every minute. I enjoy the effort that folks here put into their projects to make it theirs.