lonerider wrote:Why does everybody even put windows in Cargo trailers? Doesn't that kinda' defeat the "Stealth" concept? I understand "to let light in", but are you really inside that much?

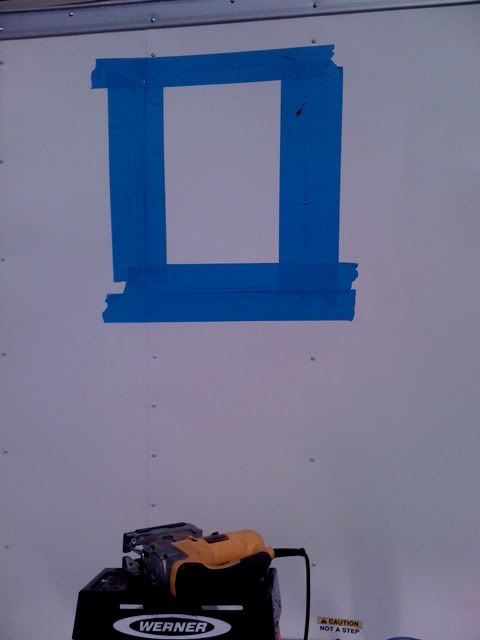

I'm putting in windows for ventilation. Not planning on AC. Also, to check for bears. ;-) Besides, you'll spend about a third of your day in the trailer, more if it rains. To me, it's worth the money to be able to see out on a rainy day while sipping a nice Costa Rican coffee AND have the cross ventilation. JMO. YMMV.

That said, no windows does contribute more to the 'stealth' appearance, and, if that is your goal, great! Go no windows. It's all about what you want. That's why we build instead of buy. You get what you want that way.

Best,

WA