OK, so we bought a Commercial Cool (Haier) portable 8k btu a/c unit via Home Depot. It is a single hose unit, meaning (once I did my research after I bought it... too typical of me

) that apparently it isn't as efficient as a two hose unit. Apparently the difference between the two is that a single hose unit exhausts hot air that has passed over the condenser to the outside via a hose. Feed air is drawn in through the back of the a/c unit via a large open to the CT interior vent/grill. What that does is create a vacuum within the CT so that any nooks and crannies in the CT that are not adequately sealed, of which there are many no matter how water tight you think your CT is, well those nooks and crannies allow hot outside air to be sucked into the CT (because you have a vacuum created by the single hose a/c unit, making them less efficient than dual hose unit). As I understand, a dual hose unit exhausts hot air through one hose and draws in out side air from another, no vacuum is created within the CT so the CT is positively charged with cool air from the a/c unit and that creates a positive pressure within the CT pushing cool air out of those nooks and crannies. Makes sense to me now that I understand how both a/c unit types function.

OK, that said, so you, like me, plunked down your hard earned money for a single hose unit and find it struggles to keep your CT cool because all those nooks and crannies are letting hot outside air sneak into our CT and making your a/c unit work harder, hence less efficient. What to do about that?

I believe I found the answer and the answer is "Fat Daddio's" baking pans.

I measured the back open grill area of my a/c unit and found that a 14x14 cake baking pan would cover the area. So I got on the internet and went in search a 14x14 pan with sufficient depth to meet my perceived needs. Bingo! Fat Daddio's sell multiple size cake baking pans. I found they had a 14"x14"x 2" deep pressed aluminum pan. Perfect!

I ordered one for $15. It arrived today. With pan in hand now, my next trip was to Home Depot to find suitable flanges (standard 4" dryer vent stuff) to connect a 4" hose to the pan and then to an external inlet in the CT wall (or floor), along with a Milwaukee 4" hole saw. I found everything I needed at Home Depot.

The sequence of pics below are of the back of my portable a/c unit, and the Fat Daddio's cake pan vent fabrication. The fabrication will be described above each pic.

Back of the portable a/c unit showing the exhaust tube outlet (the round hole), and the inlet vent (the big square grill area) to be covered by the Fat Daddio's cake pan:

The Fat Daddio's cake pan after I drilled the 4" hole with the Milwaukee 4" hole saw, something I learned with this experience about cutting a 4" hole in a cake pan, make sure you have a solid backing such as a big chunk of wood underneath that you are cutting against.

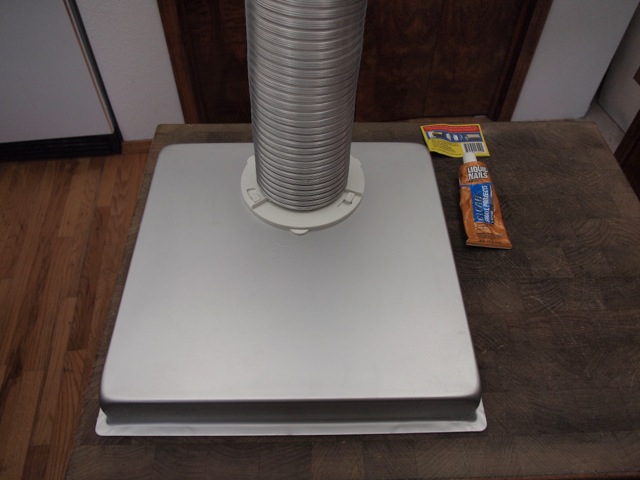

While at Home Depot wandering about trying to figure out what I needed to connect the inlet line to the "Fat Daddio's" cake pan I came across this item: "DryerDock, The Dryer Hose Quick-Disconnect" (made in the USA by VentPro, Inc.). Basically it is a very short turn quick-disconnect dryer hose adapter. It has a 1" long flange on both sides to attach a standard 4: dryer hose to. I cut the flange down to 1/4" with a hacksaw on the flange side that inserted into the "Fat Daddio's" cake pan. I drilled three 3/16" holes through the cake pan to match the flange attachment holes, then used liquid Nails clear adhesive to seal the flange to the cake pan then used 3/16" aluminum pop rivets to permanently attach the flange to the "Fat Daddio's" cake pan.

By the way, yes I know the flange is not properly centered (left to right) on the "Fat Daddio's" cake pan. It was 100 degrees here in Boise today and seemed hotter in my closed garage. I was sweating bullets and wasn't too concerned with centering since it makes no real difference in efficiency and anyone that cares to get behind the a/c unit to look and tell me so, well they can kiss... uh oh. Be nice Don.

The next two pics show the air inlet tube quick-disconnet flange attached and the air inlet hose attached to the quick-disconnect flange (the tube will be clamped to the flange with a 4 1/2" hose clamp). The hole idea of the quick-disconnect is so we can detach the exhaust and inlet hoses and strap the portable a/c unit to the CT wall for travel.

Next up will be attaching the "Fat Daddio's cake pan to the back of the portable a/c unit and then cutting a hole in the CT sidewall or floor (I am undecided at this point where to take the inlet from i.e. through the sidewall of the CT or the floor). I would prefer the floor but am concerned about inlet air sucking in hot exhaust air if I go through the floor so am thinking going higher up through the sidewall would be better for a/c unit efficiency. Any thoughts would be appreciated.

Don

I'm rapidly learning that different BBQ grills cook differently... a whole lot differently.

I'm rapidly learning that different BBQ grills cook differently... a whole lot differently.

) that apparently it isn't as efficient as a two hose unit. Apparently the difference between the two is that a single hose unit exhausts hot air that has passed over the condenser to the outside via a hose. Feed air is drawn in through the back of the a/c unit via a large open to the CT interior vent/grill. What that does is create a vacuum within the CT so that any nooks and crannies in the CT that are not adequately sealed, of which there are many no matter how water tight you think your CT is, well those nooks and crannies allow hot outside air to be sucked into the CT (because you have a vacuum created by the single hose a/c unit, making them less efficient than dual hose unit). As I understand, a dual hose unit exhausts hot air through one hose and draws in out side air from another, no vacuum is created within the CT so the CT is positively charged with cool air from the a/c unit and that creates a positive pressure within the CT pushing cool air out of those nooks and crannies. Makes sense to me now that I understand how both a/c unit types function.

) that apparently it isn't as efficient as a two hose unit. Apparently the difference between the two is that a single hose unit exhausts hot air that has passed over the condenser to the outside via a hose. Feed air is drawn in through the back of the a/c unit via a large open to the CT interior vent/grill. What that does is create a vacuum within the CT so that any nooks and crannies in the CT that are not adequately sealed, of which there are many no matter how water tight you think your CT is, well those nooks and crannies allow hot outside air to be sucked into the CT (because you have a vacuum created by the single hose a/c unit, making them less efficient than dual hose unit). As I understand, a dual hose unit exhausts hot air through one hose and draws in out side air from another, no vacuum is created within the CT so the CT is positively charged with cool air from the a/c unit and that creates a positive pressure within the CT pushing cool air out of those nooks and crannies. Makes sense to me now that I understand how both a/c unit types function. I ordered one for $15. It arrived today. With pan in hand now, my next trip was to Home Depot to find suitable flanges (standard 4" dryer vent stuff) to connect a 4" hose to the pan and then to an external inlet in the CT wall (or floor), along with a Milwaukee 4" hole saw. I found everything I needed at Home Depot.

I ordered one for $15. It arrived today. With pan in hand now, my next trip was to Home Depot to find suitable flanges (standard 4" dryer vent stuff) to connect a 4" hose to the pan and then to an external inlet in the CT wall (or floor), along with a Milwaukee 4" hole saw. I found everything I needed at Home Depot.

I majored (BS) in Home Ingenuity and went for my MS in Southern Engineering.

I majored (BS) in Home Ingenuity and went for my MS in Southern Engineering.