I think that this project may be cursed. Every time i get myself into full construction mode, something comes up and stops me. This time it was a flooded basement. 2 weekends of work with a small backhoe and lots of pipe and gravel, and i'm ready to fiberglass some more.

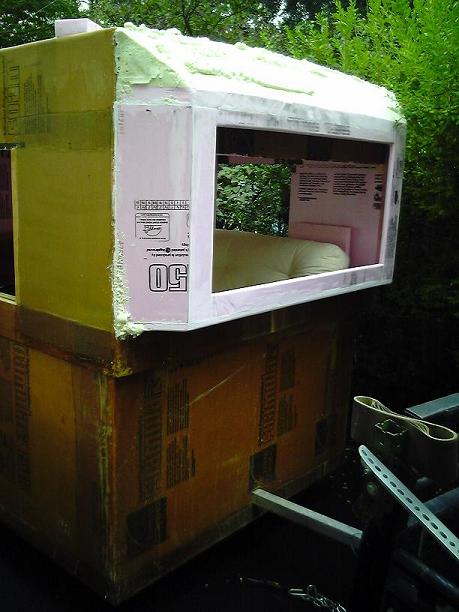

before starting work, i took a couple of pics of BUB in its "ready to camp" position.

the 2 batteries in the last pic are the group 31 Optimas i'm going to use to run the refrigerator and microwave. I have to toss them in the back every time i move BUB to get the tongue weight down to something that my back doesn't complain about.

This is what the view is like sitting on the futon and looking out what will be the front window.

After 2 beers worth of laying on the futon dreaming about BUB's first camp out, i was ready to begin work. A passing neighbor helped me remove the cap and flip it upside down in my driveway. He looked at me, then at BUB, then at the mess in the garage, then silently shook his head. No one in my neighborhood can wrap their heads around the concept of a travel trailer that weighs less than 10,000 LBS.

Without the base unit in the way, fiberglass application went pretty quick. Since there were no large expanses of foam to cover, i was able to use 12" wide fiberglass "tape" instead of cutting fiberglass off of the 5' wide roll. I was able to wet out the fiberglass on the ground before placing it on the camper and smoothing it out with a squeegee. This ends up being about 5 times as fast as trying to wet out fiberglass that is already in place on a vertical surface.

Here is one of the 12" wide 5' long rolls of tape about to be wet out.

The front fairing is now completely covered in fiberglass and ready to handle freeway speeds.

The bottom edge of the cap has also been shortened, rounded, sanded, and covered with 2 layers of fiberglass tape.

The top edges of the side window frames, and the inside roof edges have also received 2 layers of fiberglass.

I think i may only have one more good outdoor building day left before it starts to rain over here followed by getting too cold for fiberglass to flow. hopefully, i will be able to finish framing the window openings during that time.

I'm getting a 4 x 8 sheet of tinted plexiglass to cut into windows. I'll make up some poplar frames for them and hinge everything from the top. The windows will open awning style. With the windows closed, i should be able to heat the inside of bub pretty easily this winter and be able to finish all of the interior fiberglass work.

I'm hoping that BUB will be camp-able (if not quite complete) for deer hunting this year.

3 days of work, 30 beers drank.

Not a bad little bit of progress.