quote="E. Aaron Scott"]Thank you for providing such detailed pics. We love

So far it looks pretty outstanding and you are still on the frame, can't wait to see the rest of it come together.[/quote]

Thanks for your encouragement makes the hours put into it worth it

Hey Everyone it has been awhile since I have posted. I had a little bit of a setback which put a dampener on the project. Weeks and a lot of phone calls where put into how to fix the problem. Which I hope will work. Mind you its only metal and it can be fixed. So here was my problem. It was right in front of me and was known to my supplier of the Axle and neither of us realised it. I surpose its one of those things that happens when you build something from scratch and no experience. Can anyone else see it??

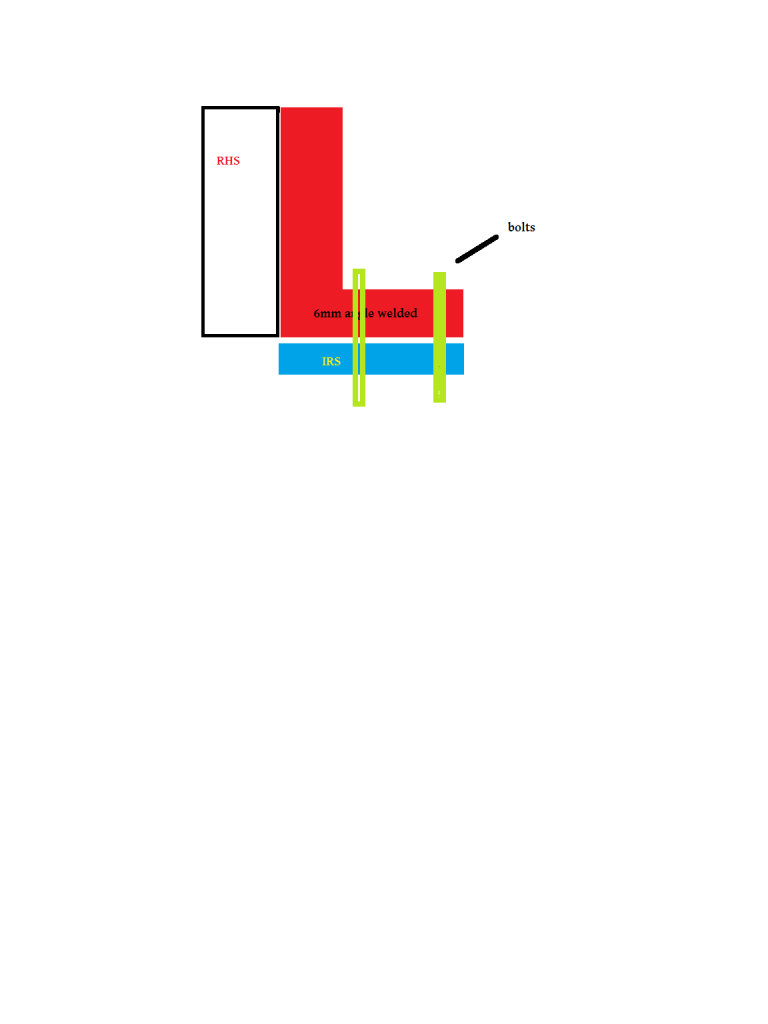

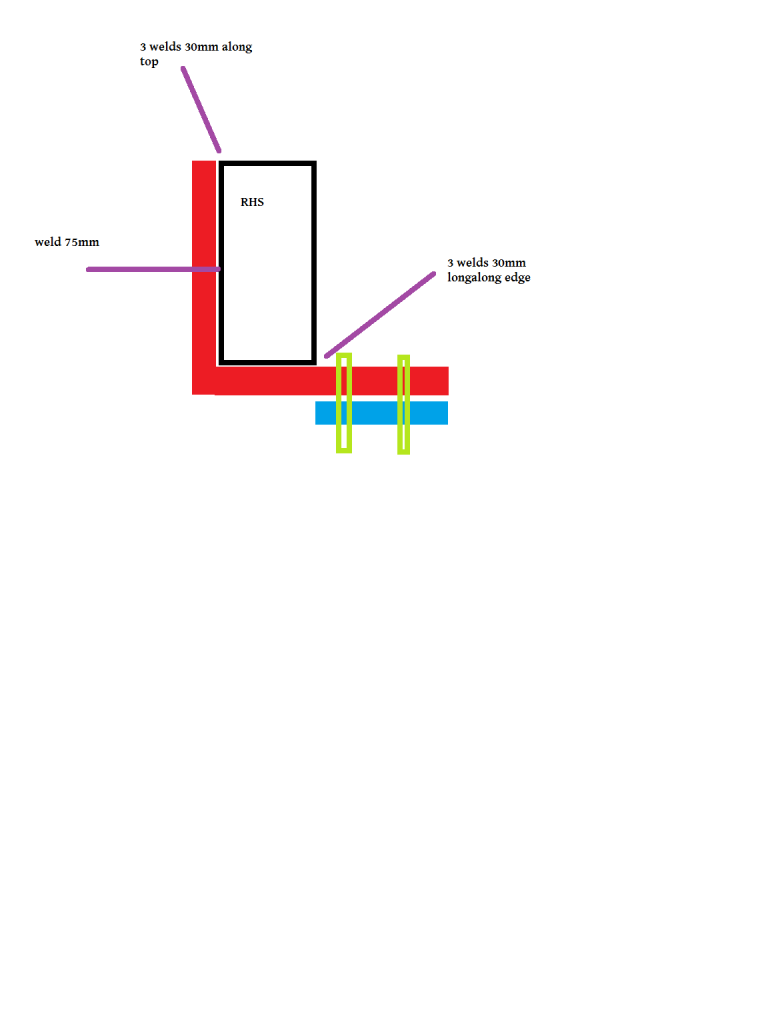

When I came to drill the holes for the bolts to hold the axle it hit me. The swing arm will hit my 6mm angle when it hits a bump or is loaded. The black rubber which is apart of the suspension sticks out 6mm and that is the same amount my angle is. Now if I had done things like everyone else, it would not be a problem as they recommend the use of the angle on the inside and the axle is bolted to that which means the weight of the van is on the welds not the chassis rails. Now if I had of known the tolerances of the swing arm where so close I would have changed my dimensions. My supplier knew I had added the angle and when I asked what dimensions he need to get the axle correct for the chassis he said I need outside rail to outside rail and inside rail to inside rail. And the axle was made to that. But I needed to know that the tolerances where so close as I would have added the 12mm to my outside measurement to have a 6mm gap from swing arm. This really ticked me but I got over it and came up with this solution. Rant over

The fix it was either chop the chassis ( not happening) order a new axle (can't afford that) or grind the plate back. I choose to do the last.

Uploaded with

ImageShack.comI have a 3mm gap. And 3mm plate still left

http://imageshack.us/a/img43/3991/rlmt.jpghttp://imageshack.us/a/img543/874/8ifo.jpg5 grinding discs

http://imageshack.us/a/img90/7929/nicp.jpgAnd heres the pile of metal.

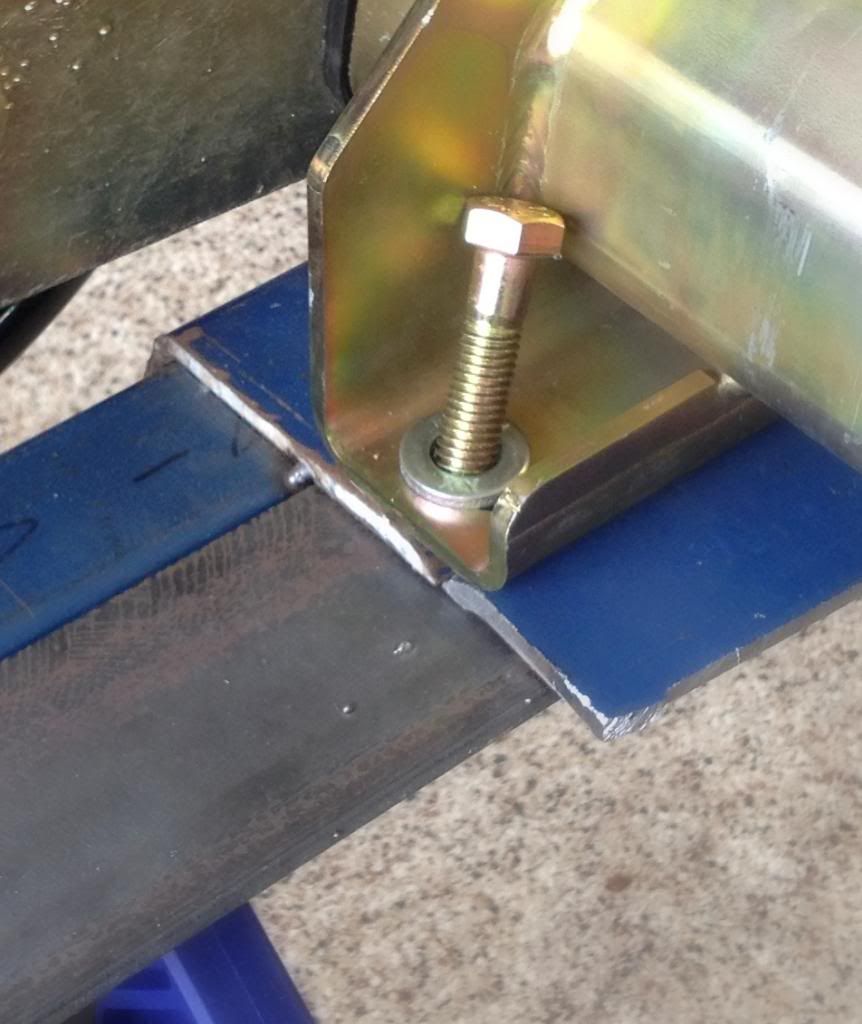

Once done and I was happy with my solution, I drilled the holes. So off the hardware I go. $50 later for 3 drill bits I quickly learnt how to sharpen them. Drilling though 12mm of steel blunts them very quickly.

Now the axle was mounted (roughly) I as able see where the handbrake cable would go and I found this happened.

http://imageshack.us/a/img824/7030/p4fj.jpghttp://imageshack.us/a/img15/3171/d5yg.jpgThe cables will rub on the rails. Nothing major but from the vans I have looked at over time rub through the chassis rails and may weaken them. So my solution was this.

http://imageshack.us/a/img46/8959/i9pi.jpgA bit of fiddling was involved to get this right but it worked.

http://imageshack.us/a/img16/8115/nxvu.jpghttp://imageshack.us/a/img407/9932/vbfq.jpghttp://imageshack.us/a/img856/8962/8753.jpgNow it wont rub

Cya Lukey

But there are so many different builds styles here that we all fit in here . . . EHH !

But there are so many different builds styles here that we all fit in here . . . EHH !