I was looking at how I did the holders for the galley hatch the other day, and thought it could be better than how I made them the first time. The holders were two 1 inch pieces of wooden dowel rod, and they folded up into the center of the inside of the galley lid, and were placed on some formed aluminum flat bar. They looked ugly hanging there, and I wanted to keep the inside of the galley hatch clear.

So I had to do some more thinking

on how to remedy this problem. I wanted some struts that would curve with the shape of the galley lid, and fold away nice and clean, plus I wanted to carry the weight of the galley lid from the furthest point from the hinge for stability.

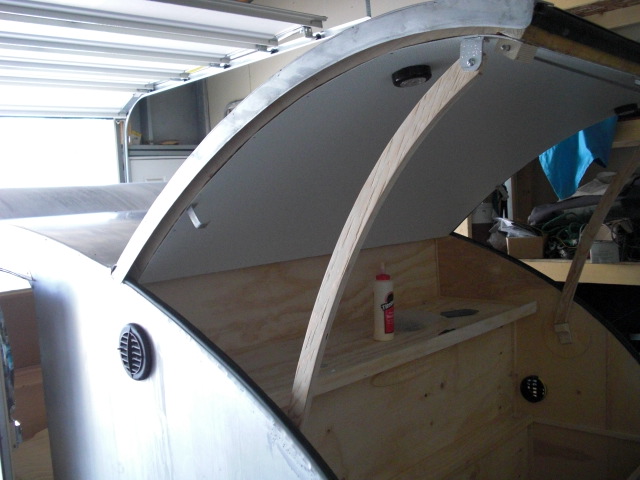

I then realized I had already cut the parts.....sort of. I had 2 pieces of 3/4" plywood that i did not use for the galley internal framework. they had the right curve need to set tight against the inside of the inner wall of the galley when folded, and they had a nice curve that would compliment the curves of the Tear Drop. This is what I came up with.

In this first photo this is a piece of pine with a 1 inch hole drilled 1 inch deep into the pine block. the curved piece of 3/4" plywood has a 1 inch piece of dowel rod screwed and glued to the end, so it will sit inside the holder.

In the next 2 photos it shows the galley hatch struts in the open and closed positions. The first pair of struts when folded closed pointed inward instead of how I have it now.

It's a funny thing about these trailers. You work on them, then a few days later you look at them and see a entirely different way of doing something on them.

I had the same question; but it sure looks great from here.

I had the same question; but it sure looks great from here.