I started constructing the doors, first working the small rear doors then I'll move to the main bedroom doors once I know it is working well. The core of the doors is the same aluminum honeycomb panel as I used for the floorboards for light weight and stiffness (don't want a warped door that won't seal). The buildup of the door layers are:

* 0.063" 6061 skin

* 0.48" aluminum honeycomb

* 0.56" foam insulation (not for small rear doors)

* 0.18" birch plywood (not for small rear doors)

1.28" total (0.54" for small rear doors if I don't include insulation and plywood)

Last year I had first planned to use the bare aluminum honeycomb panel for the external face of the door but decided to add an extra skin over it because the honeycomb panel would not match the exterior skin since it is anodized. Here's the layout of the door with hardware sitting on it as I cut it last spring along with the template I used to cut it (yes, over a year ago!)

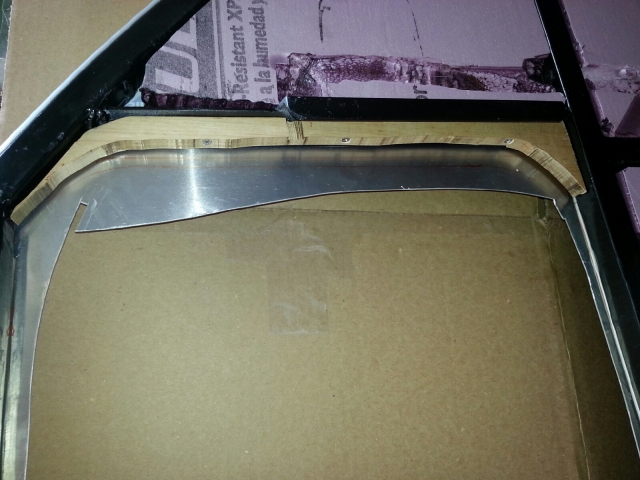

The honeycomb panel will now sit flush with the trailer exterior skin and the aluminum door skin will overlay the door opening with a Trim-Loc seal. I made a door jamb for the top to account for the curved top then trimmed the exterior skin to be slightly bigger than the honeycomb panel core:

I didn't think about my pictures when I took them but you may that some are of the left door and some are of the right (no one is not backwards, and there is a mix of pick and blue insulation). Next I clamped the door skin over the door opening to see how it fits. I had planned on a plain corner with a radius sightly larger than the core for the seal overlay but it would interfere with the trailer skin top trim so I had to find a different shape. I settled on shape to mimic the eventual jeep-style fenders that will be next to it. Here it is with the latch but no seal or hinges yet. to test the fit.

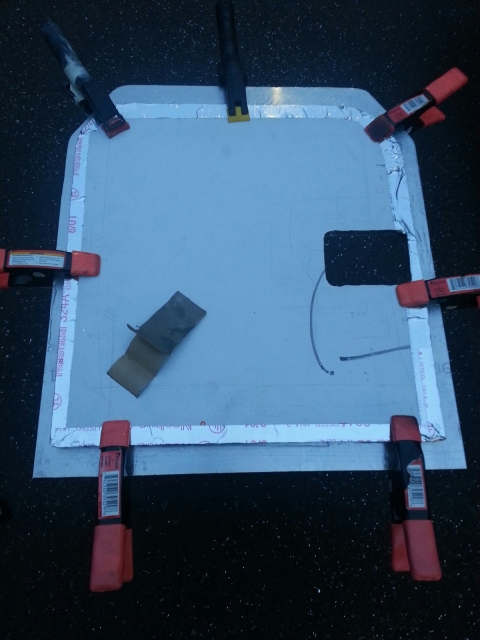

Once I confirmed the fit, I traced the outline of the honeycomb core on the inside of the door skin so I could align it and epoxy the skin on the core.

I did that work on parts of Sunday and Monday then went to work Tuesday and Wednesday. Last night I checked on one of the panels thinking I might show it to a friend but noticed that the outer door skin no longer sat flush against the trailer skin! I pushed on it a bit then saw that the epoxy between the layers was failing and after a few knocks with my bare hands it came off!

Based on my research I thought the epoxy would work but apparently not.

I had roughed up (sanded) and wiped down both surfaces before applying the epoxy, but maybe it would have helped to use a solvent to condition it before the epoxy was applied. I wonder also how much the anodized surface may have interfered with the bonding.

Next I will have to clean up the surfaces and try another method. I will try other adhesives first, plus it will eventually have 10 fasteners (3 for each of 2 hinges and 4 for the latch) to hold it, but I might have to resort to a few rivets too as a last resort. I will try

Sika on a sample or consider 3M 8115 panel adhesive (but its $50 per tube plus $60 for a tool). Good thing I'm refining this on the small doors before the big bedroom doors. I have enough extra material to make one or maybe 2 new small doors if it goes badly, but I don't have enough extra materials to redo the big doors.

I had roughed up (sanded) and wiped down both surfaces before applying the epoxy, but maybe it would have helped to use a solvent to condition it before the epoxy was applied. I wonder also how much the anodized surface may have interfered with the bonding.

I had roughed up (sanded) and wiped down both surfaces before applying the epoxy, but maybe it would have helped to use a solvent to condition it before the epoxy was applied. I wonder also how much the anodized surface may have interfered with the bonding.