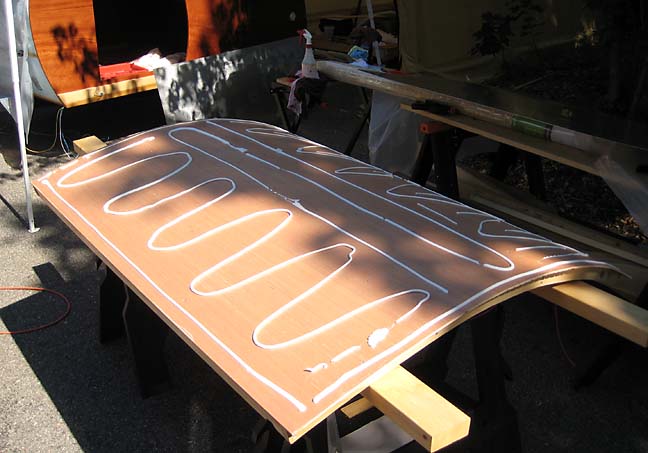

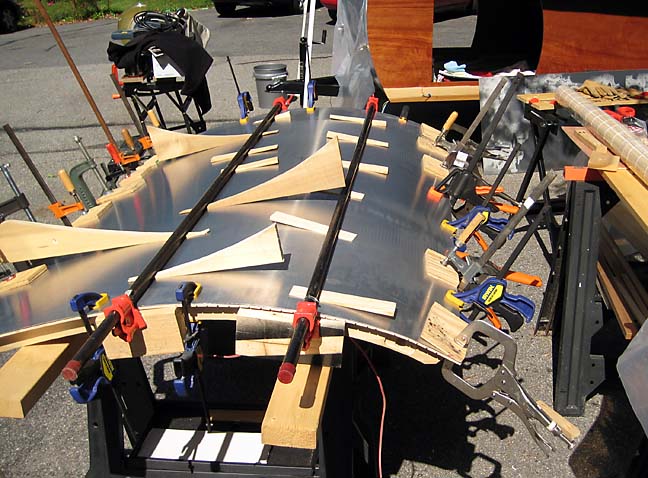

Ran kitchen light wiring inside of hatch. Glued and clamped aluminum skin to kitchen hatch.

Cut and attached bamboo rollup blinds to interior ceiling

Unpacked aluminum on pallet and discovered it had white stains or corrosion marks on it from sitting inside of wet cardboard

A call to the company I bought the aluminum from and some web research revealed I had stored it improperly. Luckily the back side of each piece was salvageable, only have marks from the wet cardboard on them.

Removed clamps from hatch aluminum skin, drilled holes in aluminum skin for latch and mounted T handle latch mechanism.

Cut aluminum strips for galley hatch inside edges. Cut aluminum for rear section below countertop.

Used Dremel tool to cut out bamboo ceiling for vent opening, and used pieces of duct tape to keep it the thread/binding from unravelling (they'll be covered by the vent facia)

Cut and attached piece of plastic corrugated panel below bamboo ceiling at “headâ€

Great trailer!!!!!!!!

Great trailer!!!!!!!!  Like your hatch latches.

Like your hatch latches.