Shadow Catcher wrote:As a long time weld inspector on everything from the space shuttle to logging equipment, I gotta say ya done a good job, I have seen pro's whose welds did not look as good.

Well I was not expecting that reply, that means so much thankyou Shadow Catcher.I might look at changing jobs on that response.

Heifer Boy wrote:Hey Lukey. Nice to see another Aussie on this site and looking forward to following your build. Do you have any sketches of your final design? A slide-out camper sounds really cool and I'm interested in how you are planning to join the monopan panels together. I've had a breif look at it but being a wood and epoxy guy I can't get my head around it. I'm sure you will be showing how it all comes together so keep up the photos and stories. Good luck

HB

Thanks Heifer Boy

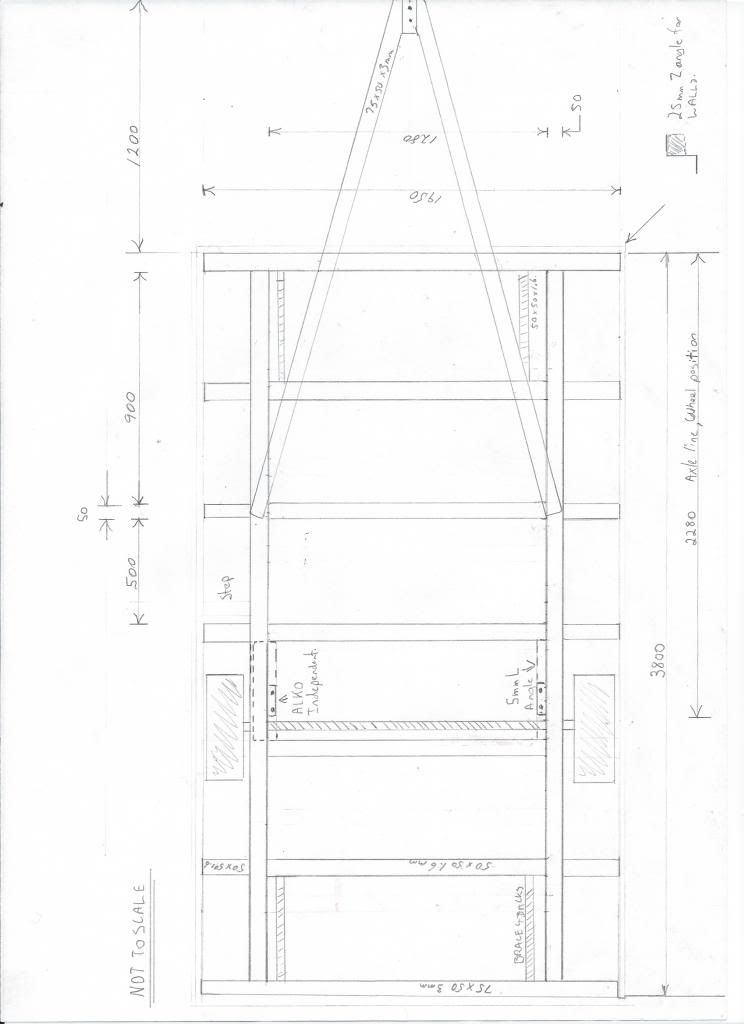

There are a few of us popping up. I have a few rough drawings but I keep changing my mind. Go with the simple shape or a bit more complex. It can bent and shaped into many ways.Being the first one I don't want to stuff up the profiles and experiment with the monopan as it could be expensive. I may not have explained myself fully. I have designs/ides for slide out/fold out but its a bit too much considering this is my first build. The kitchen on the other hand will slide out from under the bed.Joining methods well there are many

wayshttp://www.monopan.ca/about/ I'l be using there special glue,aluminum angle and rivets they supply. The rivets can hold some amazing weight the best ones 1400n pull out. I have some friends who have been there done that on another site and it seemed to work well. Its not a common product so it has been hard to get info. I was considering

http://www.Vanglass.com.au but Monopan seems easier to use.I did look at the tried and true method of wood but weight, time and life span has lead me to the later.I must keep remembering to take photos. Once the mask is on its head down bum up.

KCStudly wrote:I have to agree with Shadow Catcher, you welds look really good. I'm a little surprised that you did not grind or flap wheel sand the paint off first. Paint and other coatings make for very nasty fumes while welding and can cause contamination (tho it did not appear to do the later for you).

Nice work!

Keep up that enthusiasm, the best way I have found to do that is to put in lots of hours and post lots of pic's. We love da' pics!

Thanks KCStudly my head is not going to fit through the door anymore.

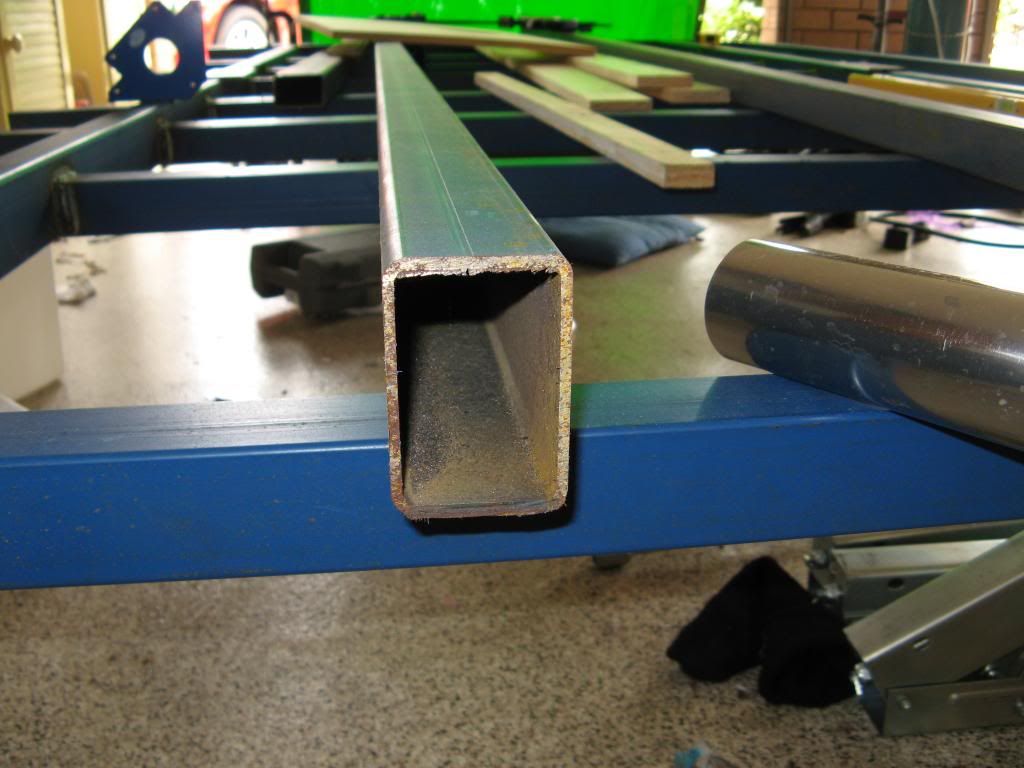

The grinding I see your point. I did a bit of looking around and the paint is special, made for welding and grinding is not needed. That is what the supplier said anyway. I did ask a fabricator on what to do which was like getting blood out of a stone. Anyway he said takes too long and if a dirty flap or grinder is used it can contaimentate the weld. I also found with practice blue painted verse bare was easier to weld as I could see the heat line better so I knew to slow it down or speed it up to get better penetration into the metal. This is evident with the white lines either side of the weld.Hours, I would love to put in more hours and photos.I'l try my best.There are more photos to come just take so long to upload. I have spent about 7-8 days so far from start to now over the last couple of months.Just have not had the time to start this thread. November and December have been so busy. But family first, toys later. Though once built it will be more family time in the van.

Cya Lukey

There are a few of us popping up. I have a few rough drawings but I keep changing my mind. Go with the simple shape or a bit more complex. It can bent and shaped into many ways.Being the first one I don't want to stuff up the profiles and experiment with the monopan as it could be expensive. I may not have explained myself fully. I have designs/ides for slide out/fold out but its a bit too much considering this is my first build. The kitchen on the other hand will slide out from under the bed.Joining methods well there are many

There are a few of us popping up. I have a few rough drawings but I keep changing my mind. Go with the simple shape or a bit more complex. It can bent and shaped into many ways.Being the first one I don't want to stuff up the profiles and experiment with the monopan as it could be expensive. I may not have explained myself fully. I have designs/ides for slide out/fold out but its a bit too much considering this is my first build. The kitchen on the other hand will slide out from under the bed.Joining methods well there are many  The grinding I see your point. I did a bit of looking around and the paint is special, made for welding and grinding is not needed. That is what the supplier said anyway. I did ask a fabricator on what to do which was like getting blood out of a stone. Anyway he said takes too long and if a dirty flap or grinder is used it can contaimentate the weld. I also found with practice blue painted verse bare was easier to weld as I could see the heat line better so I knew to slow it down or speed it up to get better penetration into the metal. This is evident with the white lines either side of the weld.Hours, I would love to put in more hours and photos.I'l try my best.There are more photos to come just take so long to upload. I have spent about 7-8 days so far from start to now over the last couple of months.Just have not had the time to start this thread. November and December have been so busy. But family first, toys later. Though once built it will be more family time in the van.

The grinding I see your point. I did a bit of looking around and the paint is special, made for welding and grinding is not needed. That is what the supplier said anyway. I did ask a fabricator on what to do which was like getting blood out of a stone. Anyway he said takes too long and if a dirty flap or grinder is used it can contaimentate the weld. I also found with practice blue painted verse bare was easier to weld as I could see the heat line better so I knew to slow it down or speed it up to get better penetration into the metal. This is evident with the white lines either side of the weld.Hours, I would love to put in more hours and photos.I'l try my best.There are more photos to come just take so long to upload. I have spent about 7-8 days so far from start to now over the last couple of months.Just have not had the time to start this thread. November and December have been so busy. But family first, toys later. Though once built it will be more family time in the van.