Ok, these are the changes I made for the foam wall. I got some 1/8" ply for both sides of the side walls. I will make a SPS panel, and then I will glue the

cedar strips to the 1/8" wall. This should make a very lightweight and strong wall.

Possible woody wall for foamie??

Moderator: eaglesdare

28 posts

• Page 2 of 2 • 1, 2

Re: Possible woody wall for foamie??

- Attachments

-

- woody wall section.jpg (144.41 KiB) Viewed 910 times

-

R. W. Alexander - Teardrop Master

- Posts: 108

- Images: 77

- Joined: Wed Jun 02, 2010 9:45 am

Re: Possible woody wall for foamie??

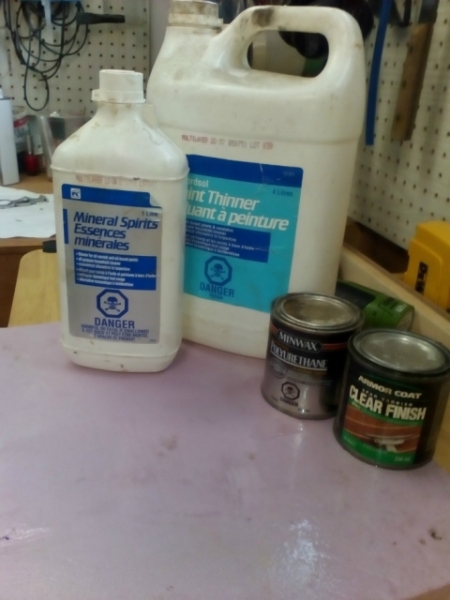

Here is the components for "the mix" I used: spar varnish(polyurethane based) and/or Minvax polyurethane and oil paint solvents like mineral spirit and/or recordsol(same stuff). I did the same test as GPW did above here. The photo below shows that the foam does NOT dissolve by these solvents, minvax or spar varnish mix within half an hour or so as the mix and solvent dry:

But when I had used this very same mix on the trailer build last year, the mix apparently remained wet for an extended period of time as I put some generous amounts on the surface of the internal compartment made of baltic birch. Some of the mix had leaked from one compartment towards the foam. It hapenned only in one out of three compartments and within a few days the foam started to soften in the area outside of that compartment bottom. It must be noted that the foam did NOT dissolve like if it would be by an acetone. It just started to loose its rigidity and became "spongy" and structurally unsound to the point that I decided to remove the damaged soft foam area and replace it with the great stuff foam. See below the finished repair area already covered with fiberglass:

Since we started this discussion I decided to look up the XPS chemical resistance properties of XPS foam online and found one refence where it has a table of chemical resistance of Polysterene foam against various hydrocarbons, not exactly mineral spirits, but petrol and diesel are close enough to it, see it on Page 3 of this document - http://www2.basf.de/basf2/img/produkte/kunststoffe/styrodur/downloads2/en/styrodur_chemical_resistance.pdf

Looks like the XPS foam may not get the effects of mineral solvent exposure immediately, but when, like in my case, the exposure was long enough, the damage in a form of softening can appear.

Hope this information will help others on this forum.

Cheers everyone!

But when I had used this very same mix on the trailer build last year, the mix apparently remained wet for an extended period of time as I put some generous amounts on the surface of the internal compartment made of baltic birch. Some of the mix had leaked from one compartment towards the foam. It hapenned only in one out of three compartments and within a few days the foam started to soften in the area outside of that compartment bottom. It must be noted that the foam did NOT dissolve like if it would be by an acetone. It just started to loose its rigidity and became "spongy" and structurally unsound to the point that I decided to remove the damaged soft foam area and replace it with the great stuff foam. See below the finished repair area already covered with fiberglass:

Since we started this discussion I decided to look up the XPS chemical resistance properties of XPS foam online and found one refence where it has a table of chemical resistance of Polysterene foam against various hydrocarbons, not exactly mineral spirits, but petrol and diesel are close enough to it, see it on Page 3 of this document - http://www2.basf.de/basf2/img/produkte/kunststoffe/styrodur/downloads2/en/styrodur_chemical_resistance.pdf

Looks like the XPS foam may not get the effects of mineral solvent exposure immediately, but when, like in my case, the exposure was long enough, the damage in a form of softening can appear.

Hope this information will help others on this forum.

Cheers everyone!

-

OP827 - Donating Member

- Posts: 1596

- Images: 414

- Joined: Fri Apr 25, 2014 7:27 pm

- Location: Bruce County Ontario

, I do need foam GPW, but I am open to hear your and all others ideas on this board about how a trailer build could be made ligher and stronger, please do share. That is why I am still here. The thickness of wood you see in the picture is only 1.5 inch deep to attach access doors. After that it is 3mm or 4.5mm think plywood for compartments that hold items inside as batteries and gas bottle, so that bumping them into the wall will not create a hole in the foam.

, I do need foam GPW, but I am open to hear your and all others ideas on this board about how a trailer build could be made ligher and stronger, please do share. That is why I am still here. The thickness of wood you see in the picture is only 1.5 inch deep to attach access doors. After that it is 3mm or 4.5mm think plywood for compartments that hold items inside as batteries and gas bottle, so that bumping them into the wall will not create a hole in the foam.