Thanks, Geep. I hope I can do as good a job as you are doing on the FS.

Okay, where do we start?

Monday I took care of a couple of divots that needed some filler. First, when I flushed off the toe board and door seal flange to the sill on the street side wall I didn’t remember my prior instructions to myself and forgot to set the depth of the bottom bearing to clear the countersunk screw holes or wire way holes in the bottom of the wall sill. When the bearing found the wire way hole for the foot light it dropped in and so did the cut, creating a “donkey track” (or as I like to call it, an “Eeyore”). It’s not quite filled in perfectly, but it will be under the Wiremold and mattress, and my goal was only to ensure against water migrating … which would have to come thru the barrier of the canvas any way, so...

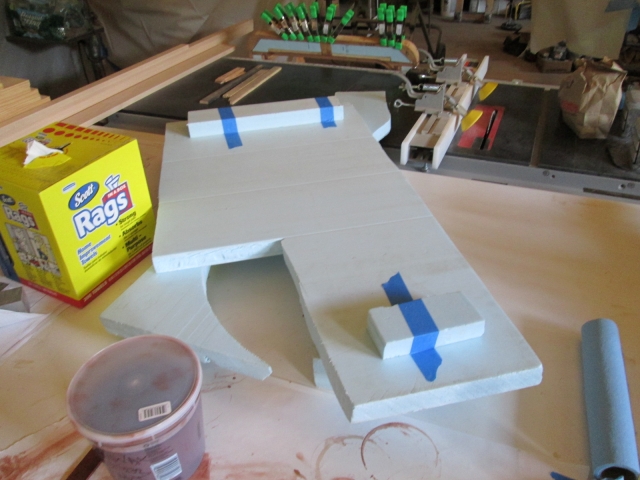

This is the back of the galley arch. The laminated wall edge was just shy of the CNC template by a whisker so when I cut the profile the inner skin was just a tad past the laminated part. A touch of filler knocked down with the Surform, a quick pass over with the small sanding block and it was good. The light colored patch in the middle is the filler.

Next I tried to scale up a big batch of the dye to color the wall inner panels. I wanted to make up a large enough batch to do the whole camper (inner walls, bulkhead, floor, ceiling, shelves, cabinet bottoms, etc.). However, when I did a color sample it was looking pink again.

Seemed like a good place to stop for the night.

Wednesday I tried adding some more dark brown to the dye batch and did another color test, but I realized that throughout all of the dye testing it was very hit or miss on the color stability. YMMV if using proper aniline wood dyes, but my luck with the fabric dyes was iffy (maybe if I had heated it up as for fabric?); too much risk and wasted time.

The maple sample stained with Minwax natural has a bit of yellowing effect to it, and the poly over that just makes it a bit more yellow. The Gunstock that I thought I would like as a contrast to the maple was a bit too orange/yellow and did not contrast enough for my taste. I wanted a richer (darker) red or the royalty of purple in an earthy brown tone to contrast with the lightness of the maple.

I had brought some small sample size cans of stain that we were checking out for the window trim selections we had been trying to make for the house, but had not tried the Red Chestnut on the Okoume since we did not like it on the pine samples we had made up for the windows at home.

Well, in a fit of frustration with the dyes, and feeling stuck, I tried the Red Chestnut on a piece of the Okoume and, lo and behold, it was about as close to what I had originally envisioned as I could hope for; a deep red brown. Maybe a little dark, but that will just make it easier to sleep in! Like I said, if it becomes overwhelmingly dark, I can always scuff and paint the ceiling between the cabinets in a lighter color.

Up early(er) on the 4th and on to the hardware store. Hmm, just one quart can of the stain. With the little can that I have it might be enough coverage, but I would rather have two cans from the same color lot, just to be sure that I don’t run out. Guy looked it up for me and found that the next Ho-de-po up the road had multiple cans (7, supposedly). Made the extra trip to find 4 cans, all dented with color oozing out the lids. The 2 cans from the same color lot were the ones with the worst dents.

Oh well, have to build on. Got them, some mixing cups with lids, some PL375 (planning for wall and bulkhead erection), some of the OSI for later use sealing exterior fittings, stir sticks, 1-1/4 x 18 ga pneumatic brads, and more 3/4 inch blue tape (except they are only stocking 0.94 inch now… make you buy more than 3/4, but cheat you on full 1 inch… what is the world coming to).

Can you see where this is going?

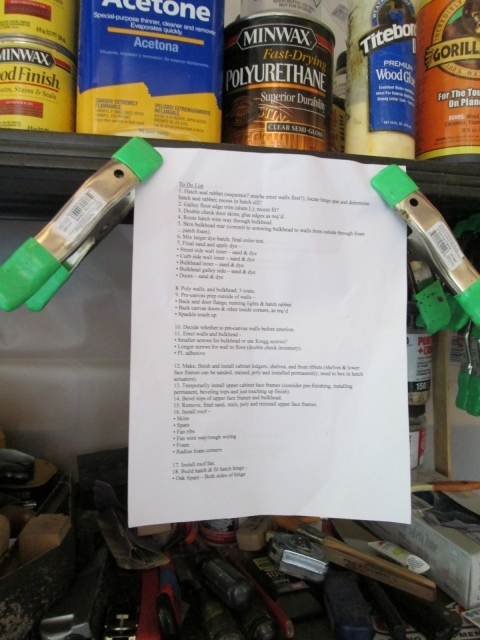

Hung a copy of my knock list in plain sight (with a few things added that I had forgotten, like galley counter, hatch handle blocking and handle, and wing tables).

Taped a piece of the freezer paper to the bench, stirred each of the cans of stain, and mixed them into a common 2-1/2 qt plastic bucket (with lid). I wanted to make sure that the stain colors are all the same throughout the project.

And here you go, street side wall inner skin stained with Minwax Red Chestnut oil stain.

I found that some of the door skin edges had lifted a bit, so I used the technique that Doug Hodder recommended to Becky for the corner of her hatch (except I used TB2 instead of epoxy); stick a thin knife in the seam and drizzle glue down in, drag the glue down in with the knife and/or a thinner razor knife, then clamp.

Did that in a few spots. Not sure if it was a dry glue issue (rolling glue on over a big area in the heat), a lack of level situation with the foam, or a lack of squeeze during the vacuum bagging process. The fix was easy enough but took some time to cycle thru the different areas that needed attention.

Moving on back to the curb side wall. I decided to take a minute and tape the foam spacer blocks that I have been using to hold the walls up off of the floor/table, rather than continue chasing them around in the wind of the fan.

Loft was up to 91 deg F and 65/ct humidity when I was happy with the coloration on the curb side inner, and finally turned the fan back on.

And one more of the street side wall peeking out.

Here is a sample of the Red Chestnut on Okoume (no poly yet) next to the sample of the maple with “natural” stain and poly. First on a white paper back drop with flash.

Then on the stainless steel drain pan of our kitchen counter w/o flash in low light.

Off to moms for a family get together. Put your feed bag on.

Melon kebobs: cantaloupe, prosciutto, mozzarella balls and a basil, scallion, olive oil pesto drizzled on top, yum. Nice ripe melon and an interesting variation on std. pesto.

Vegetable crudité: blanched asparagus, sweet peas, and baby carrots with a mild dip.

Mixed olives with feta (I didn’t actually get any of these, but they looked good).

The bowl and pick holder appear to be some of Yvette’s pottery creations.

Curried deviled eggs.

Enjoying the 4th on the deck at moms with family (me, Bill, Heather’s friend Matt, and my sis, Heather). The hanging quilt was inspired by mom and Bill’s trip to New Zealand last year.

That was the apps. Main course was BBQ chicken breast with a citrus marinade; quinoa salad with dried cranberries, almond slices and scallions; and a killer broccoli salad with hard boiled egg whites, bacon, and a sweet and sour mayonnaise and vinegar dressing (a big hit). I had stopped taking pics at this point and was concentrating on food and

.

Aunt Sandra had attempted to make ice cream, twice, but found that her fridge/freezer was failing; so she brought local dairy ice cream (fabulous vanilla), with fresh blueberries and strawberries for a lovely red, white, and blue dessert.

Sis and I talked a bit and she is no longer dead set on making the trip this year. Her situation has changed again (tho still somewhat the same) and she may choose to put it off. We will decide for sure by next week.

Sooooo, that's about a 95/ct reprieve. In about a week Yvette and I may once again have to decide what we will do for a short notice vacation here in New England; probably go north and stop in to visit her elderly aunt in Nashua; the best meatloaf sandwich ever at the cafe next to the church.

.

.

... using several different kinds of glues for different jobs , on the same trailer (or Home ) . The right glue for the right job, as exemplified by KC’s build...!!!

... using several different kinds of glues for different jobs , on the same trailer (or Home ) . The right glue for the right job, as exemplified by KC’s build...!!!  ... all glued with T2 , after a good drying out (and proper sanitizing) there were no discernible glue joint failures ... That’s pretty water resistant in my book ...

... all glued with T2 , after a good drying out (and proper sanitizing) there were no discernible glue joint failures ... That’s pretty water resistant in my book ...  or three.

or three.