BTW... I've been playing with the Styroplast and it sticks very well to most anything. I've made some small samples just to get a feel for it and it adheres well to a lot of the covering materials we've mentioned on this site. Hopefully pictures and a post tonight... ( I kinda just snuck on here at work waiting for a conference call to begin) The tests are going well enough that I am starting a larger scale test to see if I've finally settled on a material and method

Teardrops n Tiny Travel Trailers

or t n ttt for short (tnttt.com)

https://www.tnttt.com/

Web Sites w/ Foam Info For Tools, Techniques, Sources Etc..

Page 9 of 14

oh i can't wait.

Cool !!! More to play with ...  ... Thanks for the test !!!

... Thanks for the test !!!

... Thanks for the test !!!

... Thanks for the test !!!Thank you. I'll be interested to read your observations.

Well I'd like some real data on coverage and how thick it needs to be to give a good protective hard coating.

Sorry to disappoint. Just as I went to snap the photos, the flash (batteries) died. Tomorrow, I swear!!!

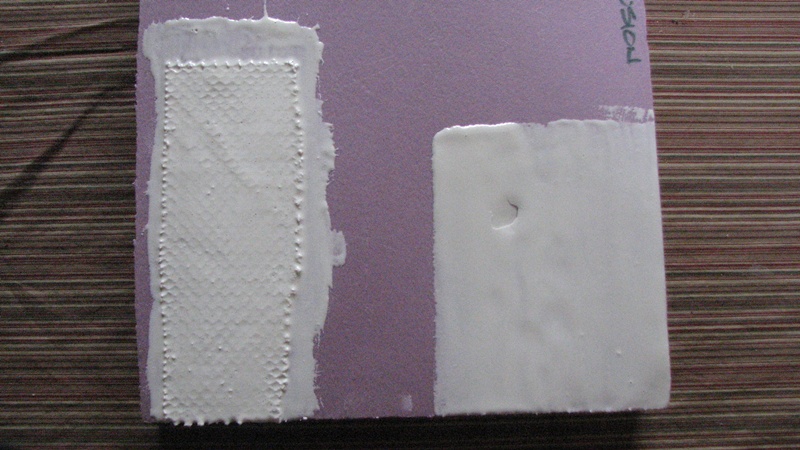

As I promised, here are the photos of my first Styroplast samples.

This picture is Styroplast over several of the different "cloths" that have been mentioned as possibilities for the "sock"

I brushed on a real thin coat of Styroplast (maybe 1/64th or /32nd of an inch) over each of the different materials. Each swatch of material is glued down with Foam Fusion from the Hot Wire Foam Factory. I'm pretty pleased with that product. The Styroplast sticks like crazy and won't be coming off unless you destroy the foam. The end result is a very smooth coat but somewhat uneven. I asked hwff about this and they replied that there is a bit of technique (artistry) involved in getting it even and they do recommend the use of a trowel to apply the Styroplast. You can also use a brush. You'll need to use acetone to clean your tools or just buy disposable tools and don't worry about it. I used a cheap china bristle brush on the sample and that's pretty apparent.

The next picture is of a corner of the foam I applied the Styroplast to. I also glued down some mesh with the Styroplast. It works, but not my favorite method. I'll use the Foam Fusion.

I let the sample cure about a day and a half and gave it a good thump with my knuckle. As you can see on the sample, my knuckle broke through the thin layer I had put on. I tried to do the same thing with the samples laid over fabric and all I got was a sore knuckle. The Styroplast is flexible though. I squeezed the corner of the foam to see if the Styroplast coat would crack and it does not.

So here are my thoughts. I will glue down fabric (probably fiberglass) with the Foam Fusion. I'll put a layer of Styroplast down over the top of that and that should provide me with a strong, flexible and smooth outer shell.

I'm playing with a larger sample and going to do my roof to wall join and see if I can get everything to work out nicely. Pics on that as I get that done.

In the meantime if you have Styroplast questions, go ahead and ask away...

This picture is Styroplast over several of the different "cloths" that have been mentioned as possibilities for the "sock"

I brushed on a real thin coat of Styroplast (maybe 1/64th or /32nd of an inch) over each of the different materials. Each swatch of material is glued down with Foam Fusion from the Hot Wire Foam Factory. I'm pretty pleased with that product. The Styroplast sticks like crazy and won't be coming off unless you destroy the foam. The end result is a very smooth coat but somewhat uneven. I asked hwff about this and they replied that there is a bit of technique (artistry) involved in getting it even and they do recommend the use of a trowel to apply the Styroplast. You can also use a brush. You'll need to use acetone to clean your tools or just buy disposable tools and don't worry about it. I used a cheap china bristle brush on the sample and that's pretty apparent.

The next picture is of a corner of the foam I applied the Styroplast to. I also glued down some mesh with the Styroplast. It works, but not my favorite method. I'll use the Foam Fusion.

I let the sample cure about a day and a half and gave it a good thump with my knuckle. As you can see on the sample, my knuckle broke through the thin layer I had put on. I tried to do the same thing with the samples laid over fabric and all I got was a sore knuckle. The Styroplast is flexible though. I squeezed the corner of the foam to see if the Styroplast coat would crack and it does not.

So here are my thoughts. I will glue down fabric (probably fiberglass) with the Foam Fusion. I'll put a layer of Styroplast down over the top of that and that should provide me with a strong, flexible and smooth outer shell.

I'm playing with a larger sample and going to do my roof to wall join and see if I can get everything to work out nicely. Pics on that as I get that done.

In the meantime if you have Styroplast questions, go ahead and ask away...

Can you get a closer shot of the first one so we can see how it looks like laying over the weave of the screen and different things?

RE: HWFF Styroplast and Other Tests

Thanks for the testing Mel! We'll all await your further experiments with it.

It looks extremely promising!

Cheers,

Norm/mezmo

It looks extremely promising!

Cheers,

Norm/mezmo

the foam fusion dries clear?

have you tried a foam to foam joint yet? or is that what you said you will be testing next? i will be interested in that.

thanks for doing this. what i don't like is the "skill" needed to apply and get that even coating. i don't think i have the "skill" or patience needed for that skill.

but i like what you have, that i am seeing so far.

have you tried a foam to foam joint yet? or is that what you said you will be testing next? i will be interested in that.

thanks for doing this. what i don't like is the "skill" needed to apply and get that even coating. i don't think i have the "skill" or patience needed for that skill.

but i like what you have, that i am seeing so far.

can the coating be sprayed? that should leave a very even thickness, unlike a brush or trowel.

eaglesdare wrote:the foam fusion dries clear?

have you tried a foam to foam joint yet? or is that what you said you will be testing next? i will be interested in that.

thanks for doing this. what i don't like is the "skill" needed to apply and get that even coating. i don't think i have the "skill" or patience needed for that skill.

but i like what you have, that i am seeing so far.

I have tested the Foam Fusion before using it to glue down the fabrics and I really like this stuff. When I glued foam to foam and tested the joint to failure, it was the foam that broke. The glue held and it does dry clear.

Below is a quote from the HWFF website about Styroplast. So it is sprayable, but I would think (I'm guessing here) that you would need pretty good equipment to spray it. It is fairly viscous after you mixed the 2 parts. Maybe someone who knows spray equipment can give us an answer about that. I'd say it is the thickness of a good maple syrup. Definitely thicker than paint...

#024-GAL - Styroplast (Gallon)

Amazing new brushable and sprayable encapsulant with fast set time that provides an impact, water, and fire resistant shell for EPS foam and Styrofoam. Whether you are producing signage or protecting detailed forms for themed scenery, or delicate RC models, Styroplast will outperform all other coatings. For industrial use.

swampjeep wrote:can the coating be sprayed? that should leave a very even thickness, unlike a brush or trowel.

On the Hot Wire Foam Factory website, they state that it is sprayable. It's pretty thick so I think you'd need pretty good equipment. I agree with you that you should get pretty nice coverage doing it that way. I'm going to send a question to my contact at HWFF and ask about spraying. I'll post their answer here.

atahoekid wrote:swampjeep wrote:can the coating be sprayed? that should leave a very even thickness, unlike a brush or trowel.

On the Hot Wire Foam Factory website, they state that it is sprayable. It's pretty thick so I think you'd need pretty good equipment. I agree with you that you should get pretty nice coverage doing it that way. I'm going to send a question to my contact at HWFF and ask about spraying. I'll post their answer here.

thinking about this, I think it was discussed, a cheap HF sprayer will work fine, and I think the HWFF person on here talked about thining it with something to spray it, but I can't seem to find where that was.

linuxmanxxx wrote:Can you get a closer shot of the first one so we can see how it looks like laying over the weave of the screen and different things?

Here are the closer photos. Sorry, I don't have the best camera, but hopefully you can get an idea...

In my opinion, the very thin coat of Styroplast did a very good job of filling in the weave of all the fabrics except for the mesh material. A thicker coat of the Styroplast would probably cover the weave of that as well.

The samples of fiberglass and the canvas that I used are much heavier than I would use in "real" life.

The thin spots in the coat could be reduced by the proper use of patience, a fine touch and the right tools/methods.

If you need any other specific observations or pics, let me know.