I’ve lost track of the days relative to the pictures left in the camera, but I think this was about 4 hrs on Saturday.

Here’s the mess I left for myself from the night before. Notice the blue tape stuck down with indication marks that I used to locate the second middle riblet in the Kregg “fixture”.

… and here it is after just a couple of minutes cleaning up. Much better.

I took all of the upper front cabinet parts back apart, trimmed the masking tape where needed, and scuffed the poly in prep for glue.

Then I used the same techniques to fit and mask off the key catcher shelf that goes across the front wall below the front cabinet. Since there are no riblets to contend with here, I was able to use the standard Kregg pocket through the “back” of the ledger into the side wall blocking.

My original “work as you go” plan was to miter these side ledgers the same as the rear cabinets, but w/o the front wall in, and with no plan to add additional wood in the front wall, I realized that I needed to leave the front ledgers “full” to allow for the screws into the sides, and switch the already mitered (and finished) side ledgers over to a coped fit. Trimming the tips of the miters off of the side ledgers was easy enough, and the edge of the miter was the perfect pattern to follow for the copes; but the screw holes that I had added already became too close to the ends and I had to add additional holes (no harm, no foul).

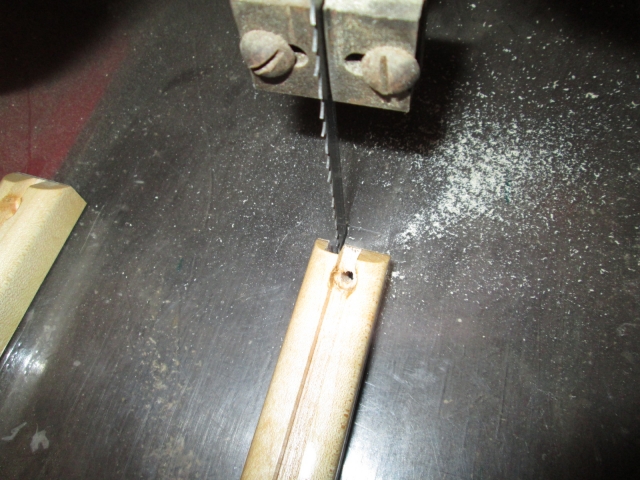

Here is a look at how I did the copes using the bandsaw.

The extra holes.

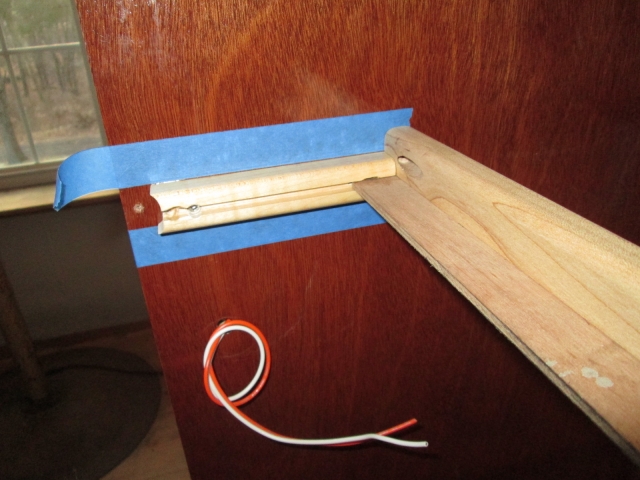

Test fitting the cope after some detail work with the 220 grit wrapped around a carpenter’s pencil.

I clamped the quick square to the wall referencing the front of the wall and the top of the front ledger, then I held the side ledgers to the square and screwed them to the walls. Once I had the side ledgers fit to the front ledger I removed the front ledger (to get it out of the way) and fit the shelf front using a piece of 5 mm scrap at each end as an alignment key.

We’re looking at the “back” (front of cabin, back of shelf) here.

The wires below the key catcher shelf are for the pillow lights (“reading” lights).

Here it is from the cabin side looking forward from the curb side doorway.

I sort of flip flopped between screwing this in and masking around it.

All the while putting many of the items I had tidied up earlier right back where they had been… only much more organized this time.

Someone on a thread I read somewhere here on the forums mentioned that their husband “had to” go use an outlet in the bath house to grind his coffee because they had not put power outlets in their camper. Well, I too prefer fresh ground coffee, but I use the classic hand cranked mill that my dad used to use.

If anyone knows the thread I am referring to, please feel free to link. Sometimes the solution to a problem is easier than we can see, but the trees for the forest. (The rubber band around the catch bin drawer keeps it from shifting open while grinding.)

I managed to get 4 hrs in on Sunday before scurrying off to Yvette’s surprise B-day dinner (her B-day is actually today).

Started by cleaning the bench again and removing the key catcher parts that had been fit and masked. Then I rubbed natural oil on all of the maple parts, avoiding areas where there will be glue.

I found a couple of areas where I could have done a better job of sanding (saw marks and router chatter), but they are not going to be prominent so I will probably let them slide.

After trimming out the mask for the key catcher where I had traced some areas, I scuffed the poly in prep for glue.

Then I transferred the front ledger locations to the side walls so that I can snap screw lines for the front wall/ceiling panels later.

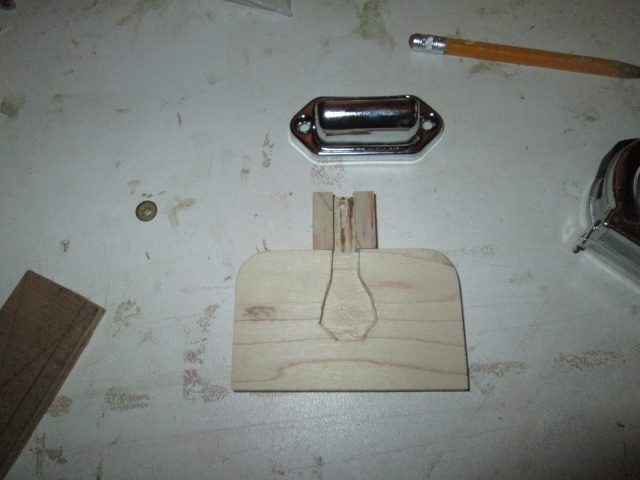

I still had a little time left, so I started working on the little trim base for the red night light that will be mounted under the rear cabinet (at our feet facing the bulkhead). I resawed a piece of 1x4 maple to match the thickness of the wire chase trim (same as the reveal between the lower edge and groove under the cabinet face frames); trimmed it to length; traced and cut the radii on the band saw; sanded the radii to the line using the small oak block; and laid out and chiseled the wire way relief in the top side. Here it is mocked up with the lamp bezel, and a scrap of the wire chase trim, as well as with a chunk of the cabinet face frame material.

Top side that will fit up against the bottom of the lower rear cabinet floor panel.

Bottom view (looking up) representing what it will look like on the underside of the cabinet.

The front edge will be coped to blend into the radius of the cabinet face frame, and the trailing edges will be rounded over to match the face frame and the wire way chase trim.

And that’s about when Karl called me on my cell (from inside the house) to remind me that I needed to go get ready for Yvette’s party… I was engrossed in my work.

No hassle. I got home in plenty of time to casually get ready and get her to the party on time… she was surprised!

Coincidentally, my good friend Dale’s sister in law (…Dale is the one with the boat) was our waitress at the

Steak Loft in Olde Mystic Village. They have a great salad bar, my usual is their teriyaki strip steak, and a twice baked stuffed potato. BIL Rene made a killer 6 layer carrot cake with coconut and cream cheese frosting; Yvette’s favorite (… “the French girl likes some wine and cheese, go figure!” …. one of her favorite self-descriptive sayings).

Took tonight off to share more b-day time with Yvette.

Weather is supposed to be warmer, so maybe polyurethane on Wednesday.

.... and testing !

.... and testing !

...I am totally crazy...

...I am totally crazy...