Back at Mecca this evening we have a couple more very small cracks that have formed on the street side of the front radius.

One at the top of the wood washer on the 2nd row of screws.

And another thru the screw hole just below the fiberglass patch.

These don’t bother me so much by themselves, but do give concern that they might propagate into something more severe, or even catastrophic.

Ben happened to be by when I arrived and recommended wetting the surface to help prevent the cracking, but also said it would probably do whatever it was going to do no matter what. I guess this has been my thoughts all along, but since he is a professional carpenter, I decided to go ahead and wet the outside surface as I proceed.

I’m not sure if it helped any, and some of the moisture wicked around the lower edge, as well as thru one of the screw holes and bled onto the inside slightly. I hope it does not leave a water mark, or at least not one that shows thru the stain.

I changed the backers around a little, hit the ratchets a few more clicks and drove another row of screws; the third row.

Progress to this point.

Taking my time and fussing around in the meantime, eventually I took another click or two on the ratchets and made some adjustments to the backer bars.

I kept spritzing with water and ran a 4th row of screws.

Slowly but surely. The ratchet straps were getting close to bearing down on the upper portion of the curve in areas that were not directly supported by the front riblets, so rather than just cinching them up more I started using wedge shims between the straps and backer blocks. That got me down under an inch to go…

Where I was able to add a 5th row of screws.

The straps were starting to sing pretty good, yet off key, when twanged; they were tight. And while trying to shift the stack of backers and shims the piles popped off of the backers. (Dagnabbit

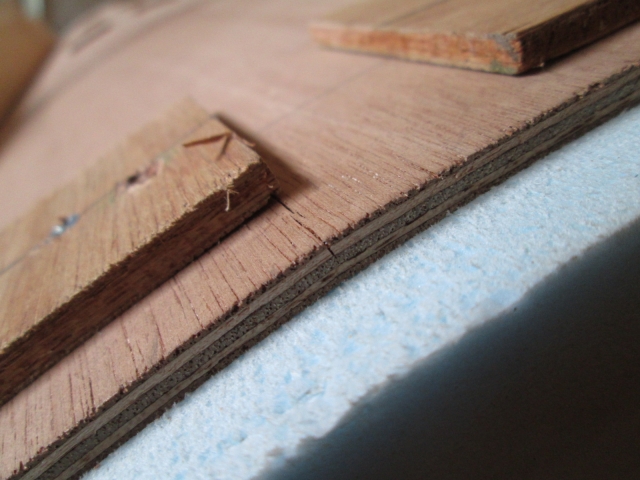

.) So I stuffed them back in there and screwed them in solid to the 2x4. Here they are after they popped out.

I’m not sure if you can see it here, but the tension in the straps looked like it was trying to torque the vent frame down into the roof. The next forward spar and the panel has a slight bow that I expect to spring back once the tension is off, but I am keeping a close eye on this for now.

So all along the cracking has only been on the street side, and I think that side of the panel is stiffer. The strap on that side twangs at a higher note and despite more tension has not pulled down quite the same as the curb side in this last go. The street side is at about 3/4 inch, and the curb side is at 5/8.

In this shot I am looking just slightly off line to show that the ceiling panel is overlapping the front wall by about 1/8 inch; no problem to shave that in place.

In this straight on shot you can see that the side edges of the panels match very well.

On the street side the overlap is a mere 1/16 of an inch; which is about what I had allowed for trimming. I know that doesn’t sound like much, but by using the strip of scrap as a story pole, I was pretty confident in the final measurement, and already knew that the curb side was different by about 1/8 inch (1/16 at the bulkhead and another 1/16 variation in the length of the wall, as best I can tell).

Side to side on the street side the ceiling ran off by only about 1/16, so overall I am thrilled with the outcome (so far).

. My heart sank a mile and I was instantly on the verge of despair, turning quickly to see the impending doom. However, that didn’t happen. It wasn't a loud snick, but it wasn't too quiet either. I gave it a good once over paying particular attention to the fiberglass patch, but everything looked okay. I guess it was just settling in (fingers crossed).

. My heart sank a mile and I was instantly on the verge of despair, turning quickly to see the impending doom. However, that didn’t happen. It wasn't a loud snick, but it wasn't too quiet either. I gave it a good once over paying particular attention to the fiberglass patch, but everything looked okay. I guess it was just settling in (fingers crossed).

)

)

.) So I stuffed them back in there and screwed them in solid to the 2x4. Here they are after they popped out.

.) So I stuffed them back in there and screwed them in solid to the 2x4. Here they are after they popped out.

... and that was wood treated with the mix ( it didn’t rot, just split ) and that, well primed and painted. Disappointing

... and that was wood treated with the mix ( it didn’t rot, just split ) and that, well primed and painted. Disappointing  ... Had I even just skinned it after bending , it probably would have been fine , or at least not show the splits ...

... Had I even just skinned it after bending , it probably would have been fine , or at least not show the splits ...  ... if it’s gonna’ do it , then fill it eh ?

... if it’s gonna’ do it , then fill it eh ?