by Bruue1 » Tue Mar 27, 2018 8:16 pm

by Bruue1 » Tue Mar 27, 2018 8:16 pm

Another 12 hours on the camper today. Today I was flying solo, LilBruue was at school. Our wall panels keep going up. I have three panels for each side wall. Two panels are now attached to each side wall and the third panel for each side wall is all glued up, weighted down and drying in my the basement. Barring any unforeseen complications I should have all of the side wall panels on tomorrow.

I also got the first, bottom rear (back/boat tail) panel on today. I have the second one glued up, weighted down and drying in the basement with the two side wall panels. That should go on tomorrow too.

I had to make some long angled cuts in the pink styrofoam for that first boat tail panel. I made a jig to hep me do this well. When I first traced and cut the side panels that cover the boat tail I saved the triangle pieces that I cut off of the corners. Two ends of this triangle happen to be the two angles of my boat tail side rail on top and bottom. Each angled board does have two different cuts, its not a perfect 45 each on my tail. Its more like 41 and 49. I actually built two jigs today one for 41 degree cuts and one for 49 degree cuts. I only had to use one so far.

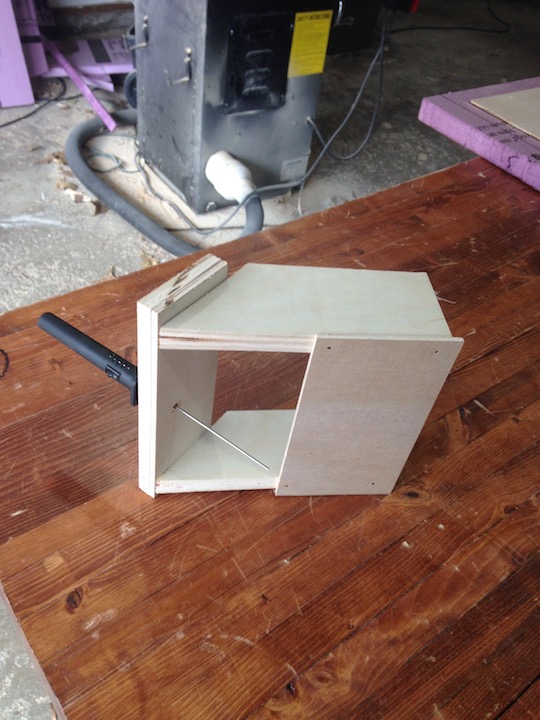

So I laid the triangle (as shown in pic 1) against the fence of my cross cut sled (you could use your mitre saw too, just place the other end of the triangle against the blade and adjust until it sits flush on the blade, or trace the triangle onto the board and cut the line with a jig saw or a skill saw). I placed a scrap piece of the 3/4 strips I had around against the triangle and this gave me the angle of cut I needed. I made two of these boards, one for each side of the jig.

I made a 3/4 top cross board the and drilled a the right size hole through it to tightly hold the collet chuck of my little $11 Nordstrand hot knife from Amazon. I drilled the hole lower in the board to increase cutting depth, it was barely deep enough the way I made this, the knife could be lower.

Then I took some scrap 1/4 for the bottom slide piece and just for fun I nailed another piece of 3/4 on the top to rest my hand on. Make sure the back edge of the bottom slide is at least straight, this tool doesn't have to be perfectly square just close, the hot knife blade moves a little anyways, because it is bendy, the knife handle should be very tight in the board and shoudn't move, otherwise there will be too much slop. If the hole holding the knife is too big and the handle doesn't sit tight just drill a new slightly smaller hole.

It was very quick to make this jig. Very easy, kind of a down and dirty or easy hack way to put this together, it works great. I ended up making two, one for each end of the triangle just because I wasn't sure which angle cut I would need when. Turned out today I only needed one angle cut for the bottom of that boat tail's two cuts, I'm guessing Ill use the same jig for the top panel too. (I only need the one jig because I'm really just transferring the profile of the flat floor up to the top of the bottom rear panel so that the middle rear panel can sit on a falt surface parallel to the floor)

Pic1 is the angle cut

Pic 2 is the jig.

Pic3 is the jig in action

- Attachments

-

- CamperWalls25 copy.jpg (75.26 KiB) Viewed 1475 times

-

- CamperWalls26 copy.jpg (111.61 KiB) Viewed 1475 times

-

- CamperWalls32 copy.jpg (116.47 KiB) Viewed 1475 times

Stumpy, Lefty and One Eye all agree: experience is the best teacher.

Wood skin inside , canvas outside … It’s GOTTA' be Strong !!!

Wood skin inside , canvas outside … It’s GOTTA' be Strong !!!