and I did just have my eyes checked, too.

and I did just have my eyes checked, too.

Moderator: eaglesdare

and I did just have my eyes checked, too.

and I did just have my eyes checked, too.

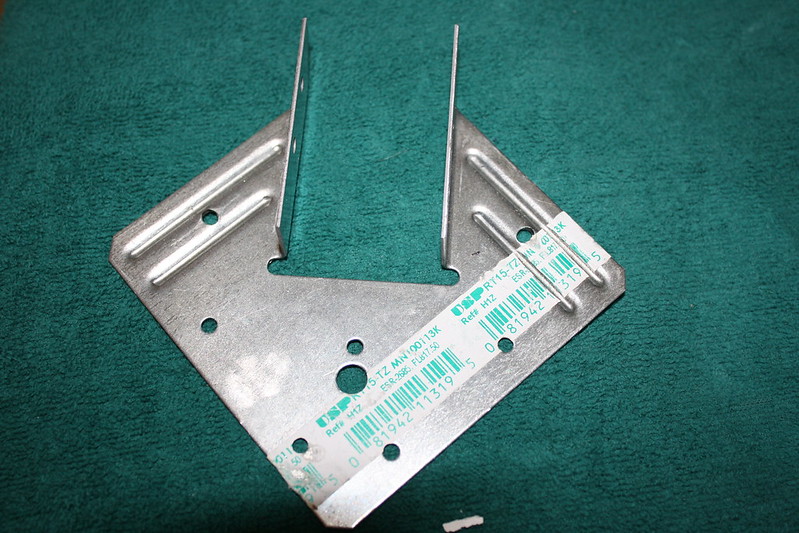

tac422 wrote:The more expensive one sign states " for use with treated wood "

KCStudly wrote:Just a hunch...

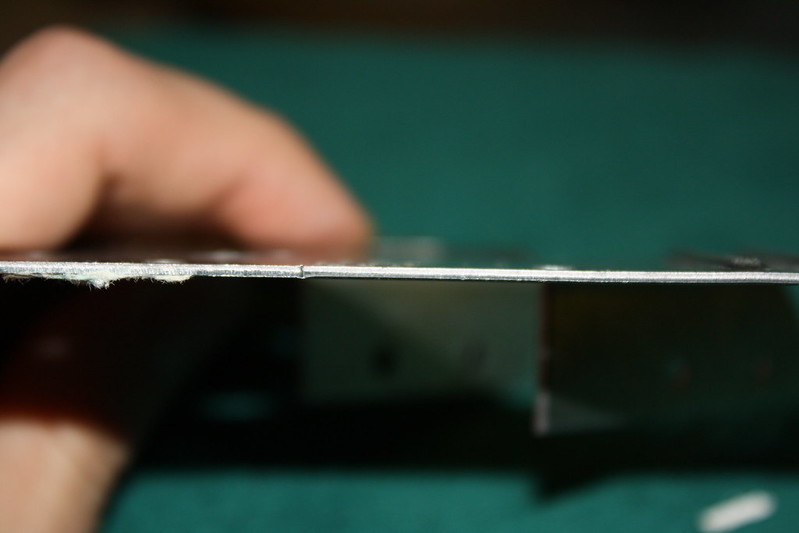

Look at the edges of the galv'd ones. I suspect you will see that the edges also have galv. on them as if they were plated after stamping and forming. If this is the case I would use them.

If the edges are raw that means that the part was stamped out of galv. sheet stock and they did nothing to treat the edges. In the later case you will get rust from the untreated edges.

The "gold" may be a zinc chromate plating (or something inspired to look like it). If the galv. ones are raw on the edges this second treatment is probably the OEM's way of solving the rusty edge problem.

KCStudly wrote:I think, more to the point, if either are not finished on the edges, you will probably want to paint them.

I would go with the regular galvy, give them a good wash in soapy water to remove residue, install, then blast them with spray bomb (aerosol spray paint in disposable can).

KCStudly wrote:Suit yourself. If it will bug you fix it, if you want to get on with it, build on.

Sounds like you have a pretty good grasp of the situation.

You could get crazy detailing every part (lord knows I do), but I would be reluctant to recommend that as a normal habit, lest you spend two years (like me) building and still not have a roof on your cabin... let alone the cabin attached to the trailer... and have never slept in it.

My build thread should have an update sometime later tonight.

My build thread should have an update sometime later tonight.

Corwin C wrote:Just FYI on the hurricane brackets. The zinc coating on any galvanized metal will react with some of the residual chemicals in pressure treated wood. The "gold" brackets are simply using a corrosion inhibitor other than zinc or at least putting a secondary layer between the pressure treated wood and the zinc. Also, zinc protects the steel by acting as a sacrificial anode to prevent corrosion. It will protect bare steel for a considerable distance, so scratches and other defects in the finish do not compromise the protective qualities. The untreated edges of the stamped metal are still protected by the zinc on the two faces. I have seen these brackets that are hot-dipped which would be the ultimate in protection because of the thickness of the zinc coating.

.. so might you’d paint that eh ? .. over the galv.

.. so might you’d paint that eh ? .. over the galv.  Hmmm?

Hmmm?  Just as much as you’d want to protect the timbers, so the plates too eh ?

Just as much as you’d want to protect the timbers, so the plates too eh ?

GPW wrote:OK, what about a thorough spray of undercoating before installation ? We’ve found with things sitting out in the weather , corrosion sets in eventually and so some type of protection must be applied , now or later ... admittedly I do live in a very WET environment , which hastens this process... so some type of coating is mandatory here if you want any metal to last ...

Besides if you sprayed them black , they’d look Cool too ...

On many farm trailers, (hay wagons are a prime example) I use heavy chain to secure wooden bodies to steel chassis. The reason being is that the steel frame will flex a bit while in use. By allowing the body of the trailer to float a bit, this should help keep things from breaking.

Also, wood expands and contracts at a much greater rate than metal. It should be allowed to move a bit. I suspect that bolting it down will lead to warping, loosening of the bolts and poor long term durability. I'd just use wooden blocks to prevent the body from moving fore/aft and side to side and the chain to keep it from lifting off.

BTW, I'm NOT an expert in the department. FWIW. I don't even play a doctor on TV. YMMV.

Users browsing this forum: No registered users and 11 guests