That travelino is fascinating alot of stuff for only 1650 lbs but the whole trailer is made of light weight fiber reinforced plastic parts. They have a cool virtual tour on their web site. the bathroom has a interestng swing in and out door to save space. I like the wrap around table set up.

Gary

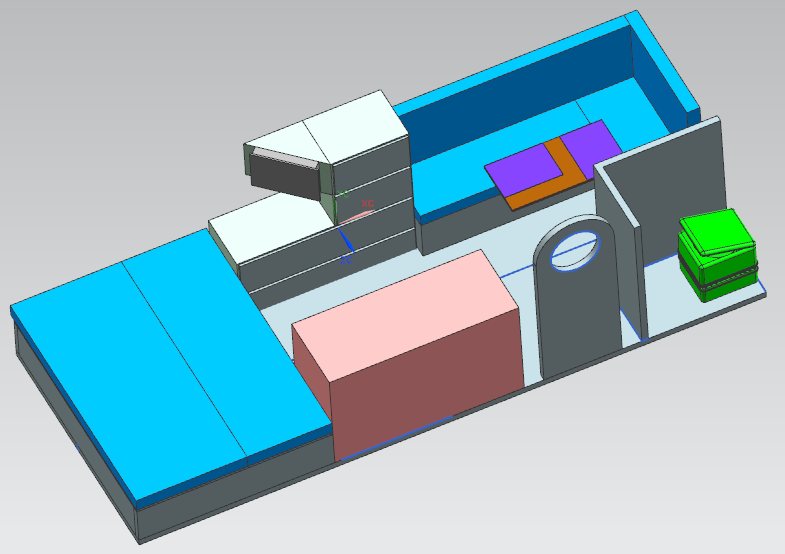

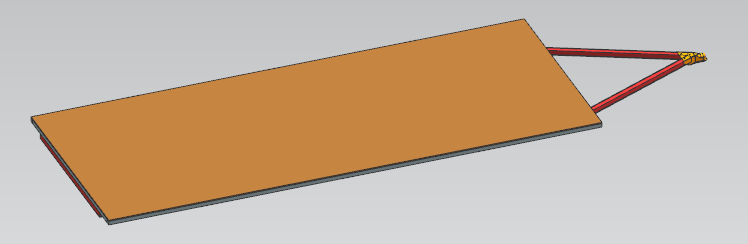

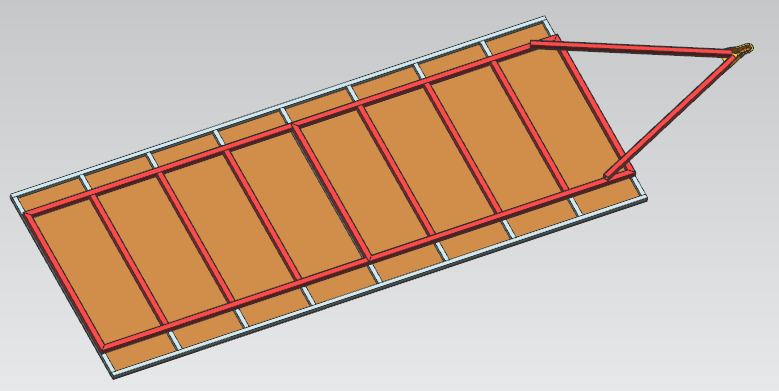

I think it's time to build another one...

Moderator: eaglesdare

-

RAYVILLIAN - Lifetime member

- Posts: 1434

- Images: 109

- Joined: Thu Aug 05, 2004 9:33 pm

- Location: Rayville MO

Re: I think it's time to build another one...

alchemist77 wrote:Why a side door? Like GPWs escape vehicle it seems like the best option is the door on the back. Opening to galley, bathroom, upright storage, half bed,bench on each side.

Sent from my Alcatel_5054O using Tapatalk

Speaking from the experience with the Ladybug WW, which had no side doors, I wished I had installed them. it was a PITA to always have to raise the hatch to get inside or crawl through the air conditioner hatch. Side doors make a quick and easy access to cargo and interior - Plus if you need a quick nap time while travelling, you really don't need to raise the hatch!

-

starleen2 - 5th Teardrop Club

- Posts: 16272

- Images: 224

- Joined: Sat May 12, 2007 8:26 pm

- Location: Pea Ridge ,AR