Happy mother’s day to my mom, and all of the mothers out there in TNTTT land!

GPW wrote:Getting close now KC !!!

Thanks GPW. We all keep thinking that, and I keep being asked, “when do you think you’ll get (insert: walls up... box done... just plain done, etc.)?”

I’m too busy trying to think 2 and 3 steps ahead that I can’t even begin to think of the time frames in the bigger picture.

Here is my to-do list for the near term, not necessarily in order:

- Fair both wall outside surfaces with spackle

- Finalize the hatch actuator switch mounting and fail-safe circuit

- Skin both wall inner surfaces

- Layout and predrill the floor for the wall mounting screws

- Fair the radius corners of the floor

- Seal the bottom and sides of the floor (I will probably use slightly thinned TB2 since I have a bunch of it on hand)

- Make cut outs in inner skins for electrical stuff (light switch pockets and bulkhead fan)

- Trim walls to final finished profile

- Apply finish to top of floor, inside of walls and bulkhead (decide whether to mask all the little spots where the cabinet frames should be glued to the walls)

And on it goes.

Stopped and got some fresh spackle and plastic putty knives. Also stopped at Goodwill and got stuff for mixing and storing dye: pot for heating; measuring spoons for accurate measuring; large soup (or small serving) spoon for stirring; and a large sealed top aluminum drink bottle for storing). The only thing I couldn’t find was a funnel.

Pulled the weights, trimmed the excess, and sanded the Dutchman patch down fair.

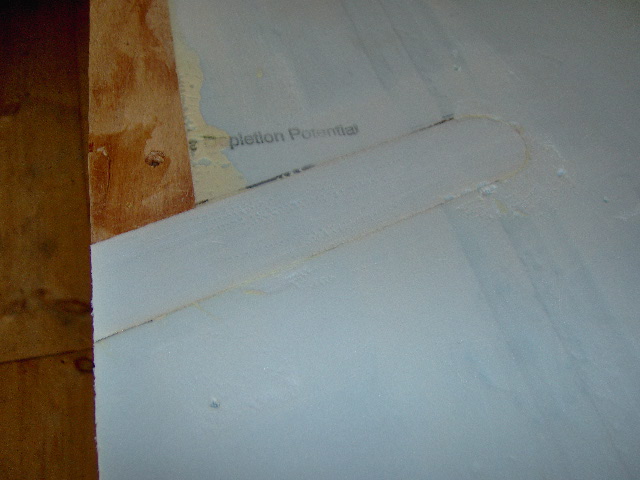

The fresh spackle behaved much better, light and fluffy, and, after making a pass with the sanding block on the stuff I put down earlier, I was able to lay down a first pass on the rest of the street side wall.

The area around the Dutchman took a little bit.

The dark area is something that I haven’t seen with the GG. I expected it to be gooey, but it was solid, and not very foam like.

The repair seems to have worked. The wall still has a slight “wave” there but no longer flexes like it did with the crack.

Here’s a shot looking up from the bottom of the front section of the street side wall showing how the fairing work is going.

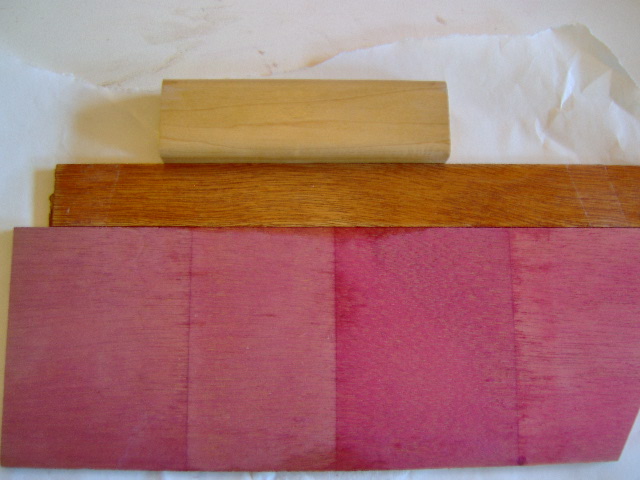

Next I experimented with the dyes. I didn’t bother heating it, nor did I add any more salt or vinegar. I used the plastic mixing cup (that I had bought previously) to measure 4 oz of water into a Dixie cup. Then I added 1 tsp of the Wine color dye. I did the same for the cherry color, and then I mixed “quarter” samples from each of these by taking 8 tsp from one and 2 tsp from the other, both ways.

Using white paper Scott towels I saturated sections of a scrap test piece of the Okoume.

I had some bleed under the tape between the sections, and the pictures look blotchier than it does in person, not to mention that the colors are not even close to what I want. They’re neat colors, just not what I want for the camper.

Here is the test piece. It is barely dry without any top coat. From left to right is: straight wine; 4 to 1 wine over cherry; 4 to 1 cherry over wine; straight cherry. (Also shown are the previous test pieces with gunstock oil stain and a couple of coats of poly on the Okoume, and the “natural” oil and poly on the maple.)

First pic with flash.

Second pic without flash.

Not much difference in the quarter shades. In the pic they all look pretty much the same, but in person the wine is more toward purple (Merlot) and the cherry is more like fuchsia (a pink shade of purple).

I stopped back by Joann’s and got a bottle of the dark brown to see if I can get it a lot closer. I’ll give it another try or two, but if I still don’t have any luck getting a color I like, I’m going to go with the oil stain.

I like purple, but I don't want it (or pink!) to overwhelm me. I want that warm wood feeling inside. I guess I was thinking that the wood would contribute more of the brown color, and that the dyes would just be tone on that, but it looks like the dye took over and the wood didn't fight back much.