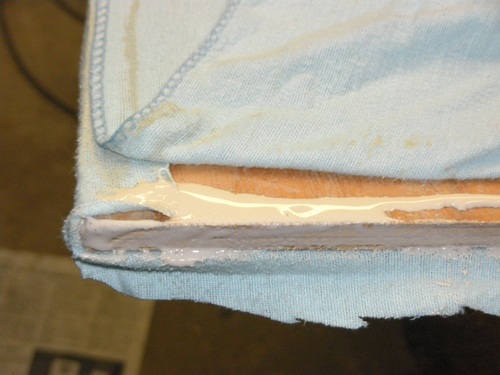

fabric/glue table (not foam, but it could have been)

I was inspired by the fabric/glue methods being used here, and decided

to test it out. I posted this way back in the Big Thread, reposting it here

hoping someone might find it useful. I am a big fan of creating multi-

purpose elements to save weight, and I think things like this could be

incorporated nicely into a foamie design...

I chose plywood for my table because I had a scrap of the perfect size,

and because I did not expect foam to provide a surface that was sturdy

enough for food prep and a big knife. Now I wish I had tried foam,

because the finished surface is solid, durable, waterproof, chop-proof, etc.

Materials I used were Titebond 3 and a old flannel sheet. I chose T3

because after reading the specs I was convinced it would best handle a

spill of boiling liquid. I did not want to paint it, since the T3 is

supposedly suitable for contact with food, but it was so ugly that I

brushed on a coat of exterior paint. The table held up well to grease

drips, blazing sunshine, hot tea cups, and even a pot of beans that

boiled over on it.

The table remained attached to the side of the trailer when camped,

and even in extreme winds, I just weighted it with rocks and/or jugs of

water. If it were made of foam I think wind would be tricky, but that

would be the only drawback.

My table attaches vertically to the front of the cabinet for travel, and it

slides into supports under the cabinet for use on a rainy day as a laptop

shelf for watching movies.

to test it out. I posted this way back in the Big Thread, reposting it here

hoping someone might find it useful. I am a big fan of creating multi-

purpose elements to save weight, and I think things like this could be

incorporated nicely into a foamie design...

I chose plywood for my table because I had a scrap of the perfect size,

and because I did not expect foam to provide a surface that was sturdy

enough for food prep and a big knife. Now I wish I had tried foam,

because the finished surface is solid, durable, waterproof, chop-proof, etc.

Materials I used were Titebond 3 and a old flannel sheet. I chose T3

because after reading the specs I was convinced it would best handle a

spill of boiling liquid. I did not want to paint it, since the T3 is

supposedly suitable for contact with food, but it was so ugly that I

brushed on a coat of exterior paint. The table held up well to grease

drips, blazing sunshine, hot tea cups, and even a pot of beans that

boiled over on it.

The table remained attached to the side of the trailer when camped,

and even in extreme winds, I just weighted it with rocks and/or jugs of

water. If it were made of foam I think wind would be tricky, but that

would be the only drawback.

My table attaches vertically to the front of the cabinet for travel, and it

slides into supports under the cabinet for use on a rainy day as a laptop

shelf for watching movies.

and the hinge squishes into it and gives under the

and the hinge squishes into it and gives under the